Bamboo Chipping Machine and Bamboo Chipping System

A chipper and bamboo technology, applied in mechanical equipment, multi-purpose machinery, sugarcane machining and other directions, can solve the problems of rough processing effect, unable to meet production needs, single function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

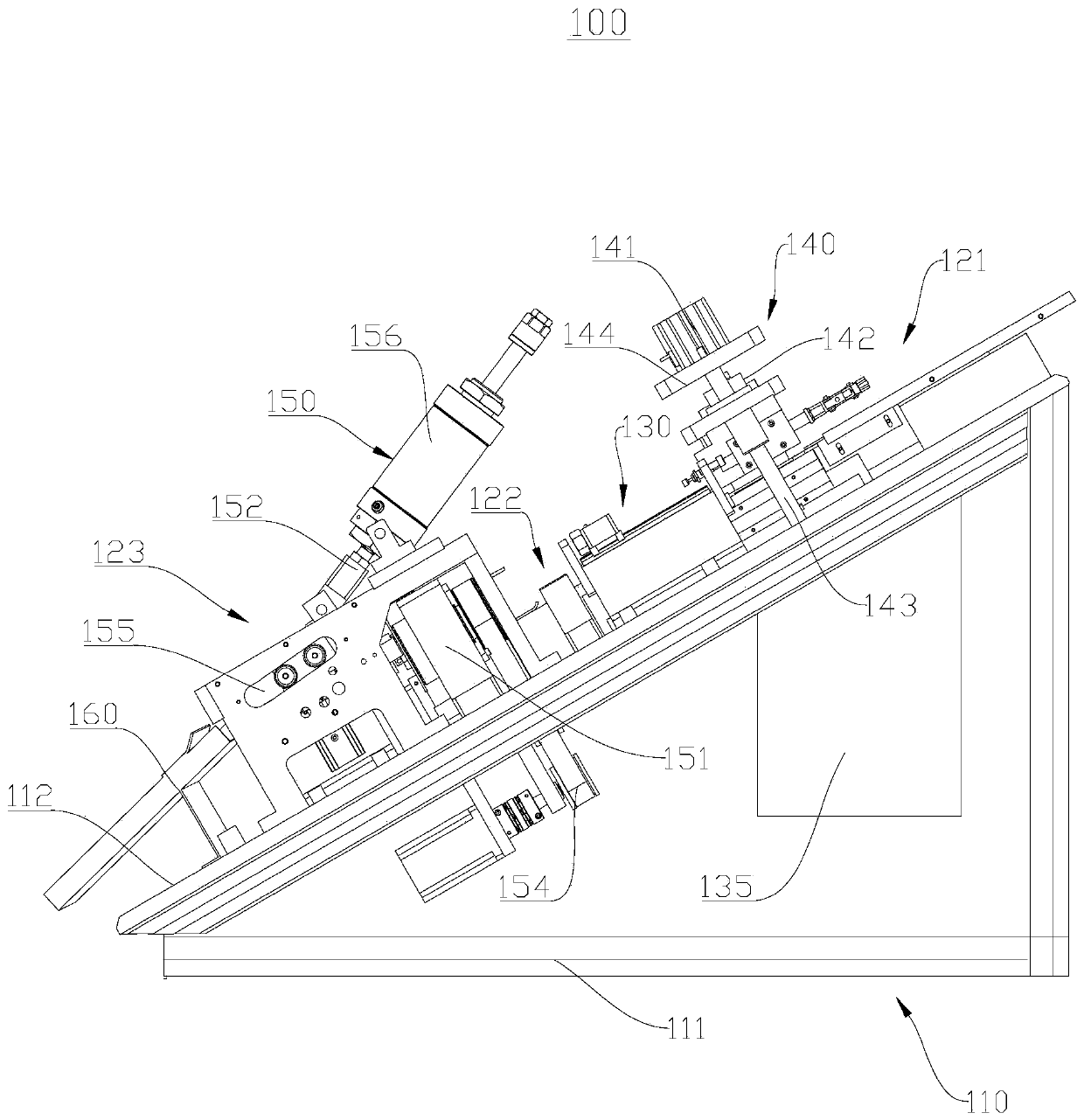

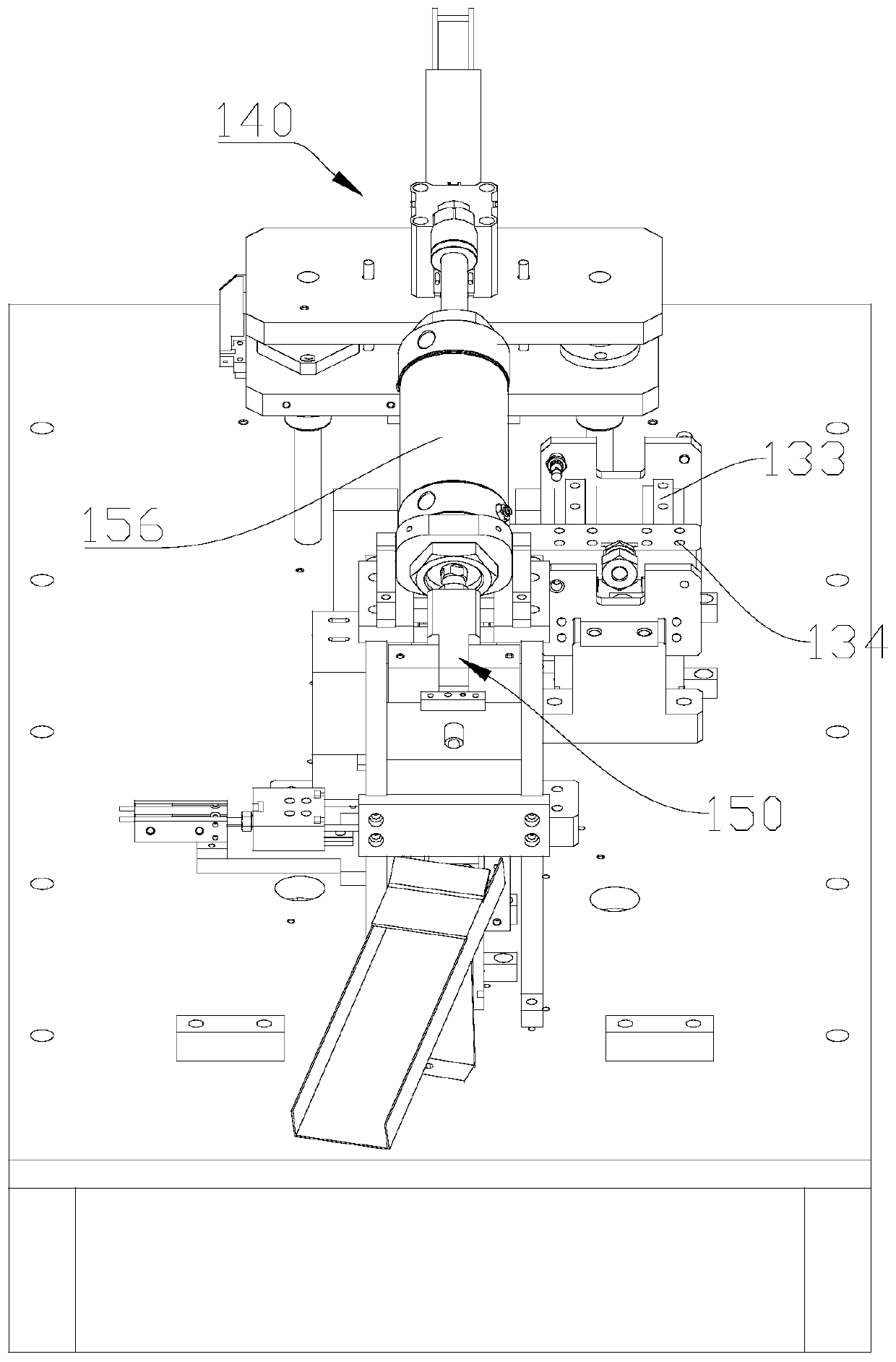

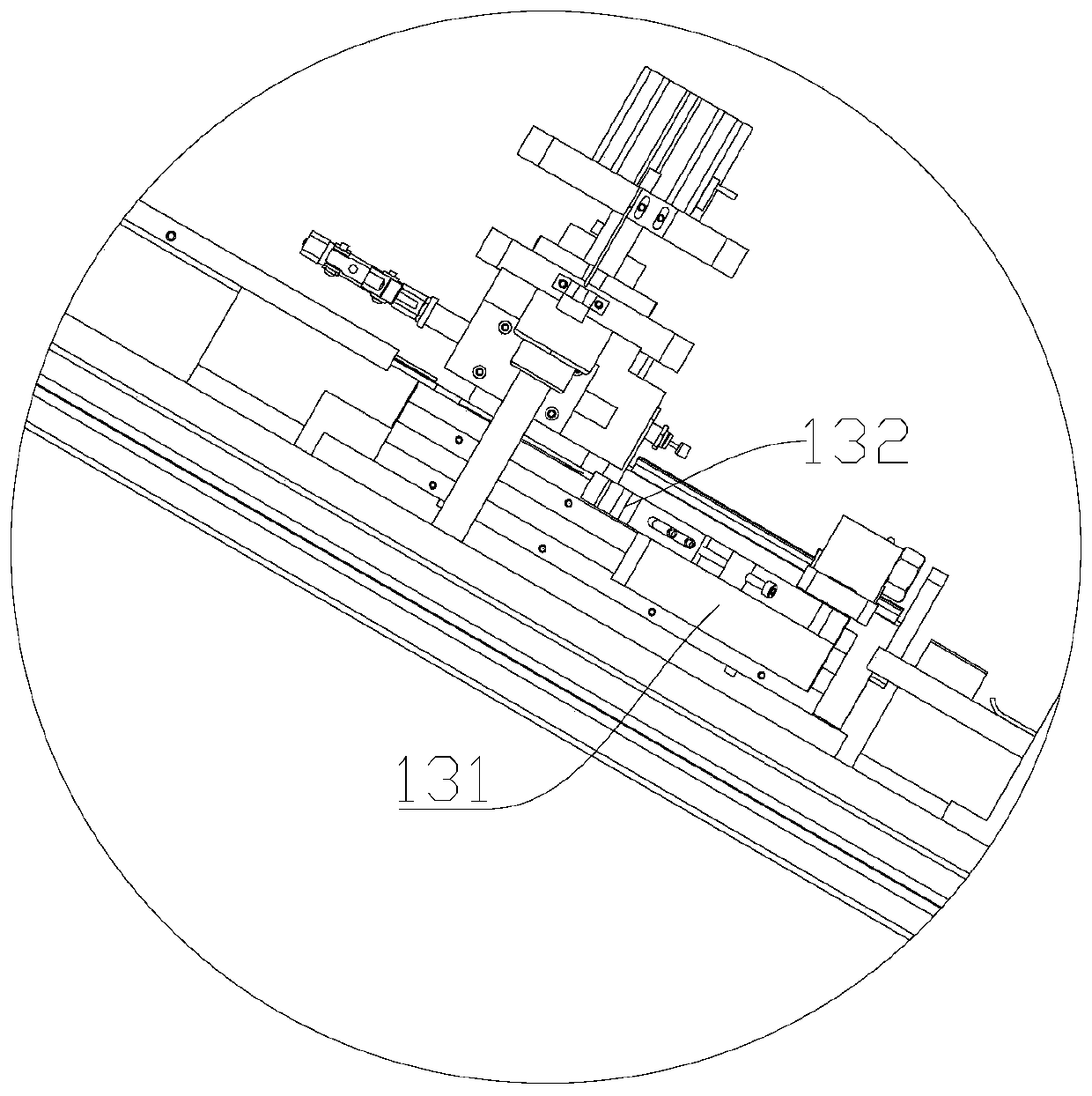

[0046] Please refer to Figure 1-Figure 4 , the present embodiment provides a bamboo chipper 100, which includes a frame 110, a conveying track, a cutting device 130 and a slicing device 150.

[0047] Further, a support platform 112 is provided on the frame 110 .

[0048] Specifically, the frame 110 includes a support column 111 and a support platform 112 . The supporting columns 111 include a plurality of supporting columns 111 connected to the bottom of the supporting platform 112 . Optionally, the support platform 112 is inclined. In other words, the heights of the plurality of support columns 111 are different. Optionally, there are four support columns 111, two support columns 111 of the same height are arranged side by side at the front end of the support platform 112, and two support columns 111 of the same height are arranged at the rear end of the support platform 112, so that The four support columns 111 set the entire support platform 112 into an inclined suppor...

no. 2 example

[0073] This embodiment provides a bamboo chipping system, which includes the bamboo chipper 100 provided in the first embodiment and an automatic feeding device. Specifically, rollers are set under the entire conveying track, and the rollers are driven by a motor, so as to realize Automatic transfer of the entire bamboo chipping system.

[0074] In summary, the present invention provides a bamboo chipper, comprising: a frame, a conveying track, a cutting device and a slicing device. Among them, a supporting platform is arranged on the frame; the conveying track is arranged on the supporting platform, and the conveying track includes the first section, the second section and the third section in sequence along the conveying direction, and the distance between the first section, the second section and the third section is horizontal The height of the ground gradually decreases along the conveying direction; the cutting device is arranged on the first section; the cutting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com