Laser marking method capable of automatically positioning products

An automatic positioning and laser coding technology, applied in the field of laser coding, can solve the problems of no detection of coding and marking information, inability to locate workpieces, and low detection efficiency, saving production time, saving labor costs, and improving accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

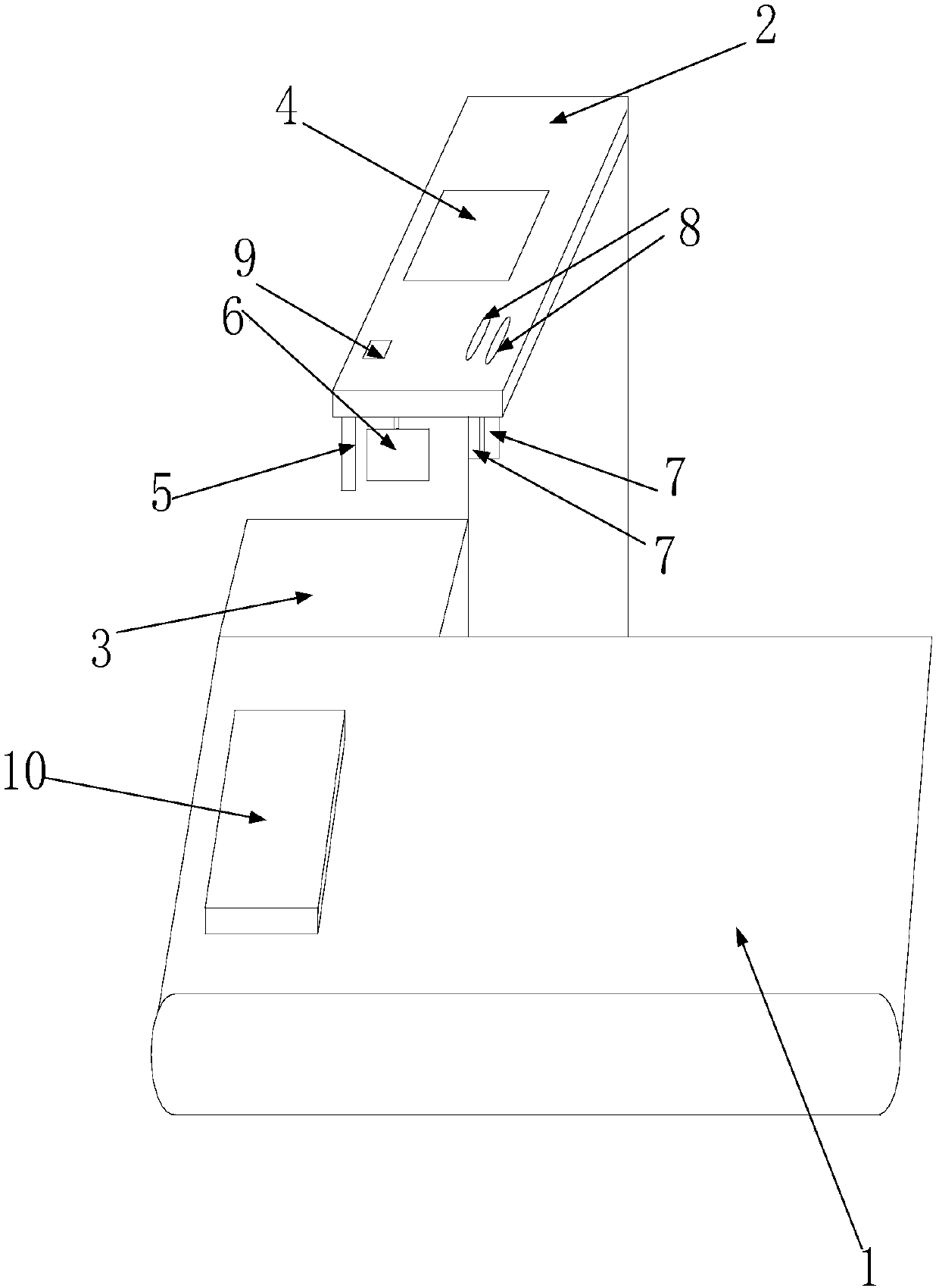

[0030] like figure 1 As shown, the laser marking method for automatic positioning of products follows the following steps in sequence:

[0031] A: Place the workpiece on the conveyor belt and move from left to right driven by the conveyor belt;

[0032] B: When passing under the positioning component, the positioning component collects the position information of the workpiece and transmits it to the control component;

[0033] C: The control component predicts the position and movement information of the workpiece according to the position information and controls the laser generator to move to the predetermined movement position of the workpiece;

[0034] D: When passing under the laser generator, the laser generator marks the set label or barcode on the surface of the workpiece;

[0035] E: When the labeled or barcoded workpiece continues to be transported to the detection component, the detection component collects the visual information of the product and transmits it t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com