Lubrication system for podded propulsor bearings

A technology of lubricating system and propeller, applied in the field of lubricating system, can solve problems such as detection of impurity content in oil, poor bearing cooling effect, and inability to detect whether there is leakage in oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

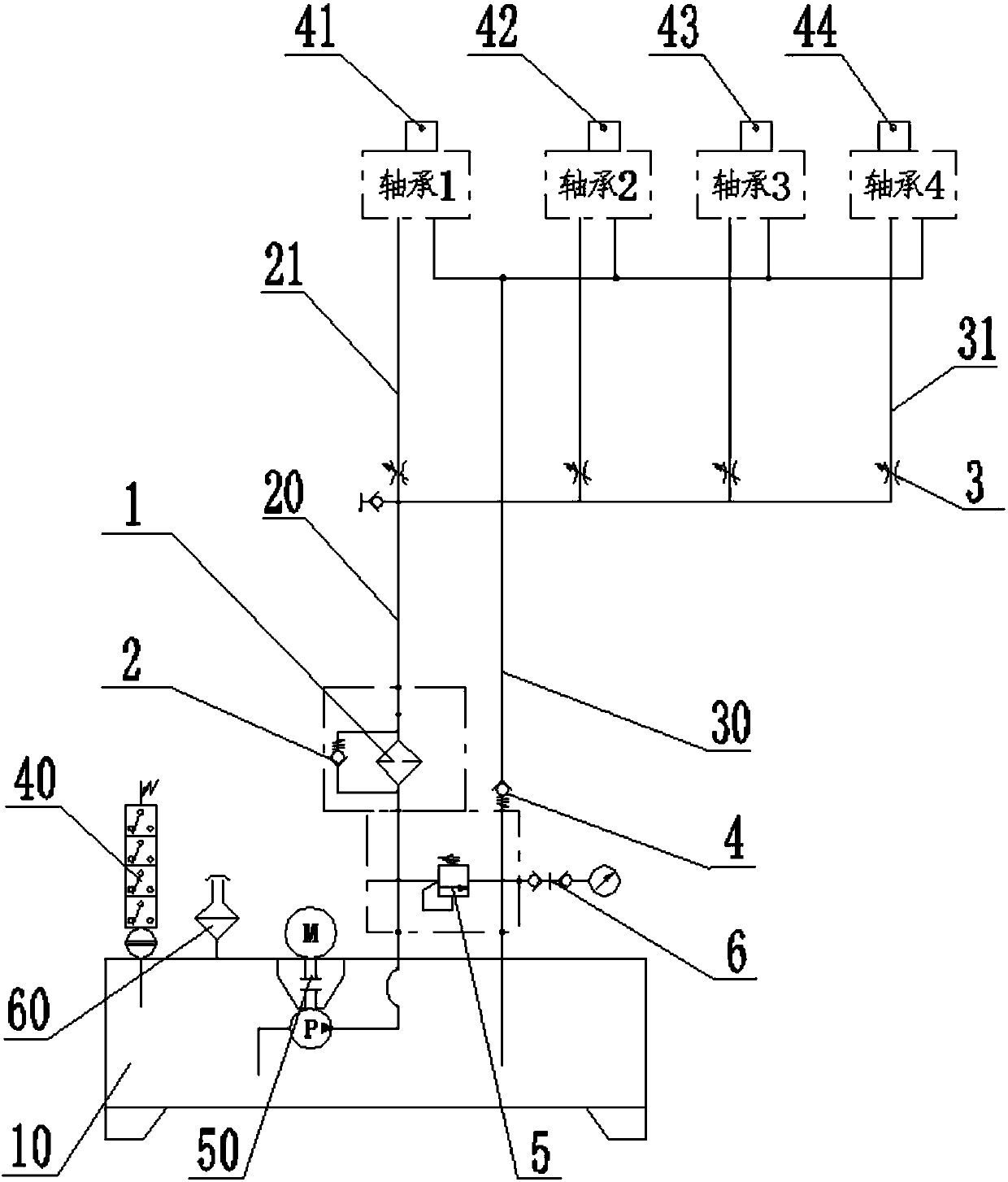

[0016] figure 1 is the structural diagram of the lubrication system for pod thruster bearings.

[0017] In this embodiment, the pod propeller has 4 bearings. like figure 1 As shown, the lubrication system of the pod thruster bearing includes: oil tank 10, circulating power mechanism 50, 4 temperature switches 40, input pipeline, output pipeline, pressure pipeline filter 1, filter check valve 2, 4 A throttle valve 3, a one-way valve 4, a pressure regulating valve 5, a pressure switch 6 and an oil detection device 60.

[0018] All lubricating oils of the whole lubricating system are all stored in the oil tank 10 . The circulating power mechanism 50 is arranged in the oil tank 10 to provide the circulating power of lubricating oil. The sensing components 41 , 42 , 43 , 44 of the temperature switch 40 are arranged at the bearing position of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com