A method and device for producing synthetic natural gas

A technology for synthesizing natural gas and product gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of lack of reactor design material-energy integration optimization, limitation of energy comprehensive utilization efficiency, narrow temperature range of catalyst, etc. The effect of cost reduction and popularization and application, improvement of comprehensive energy utilization efficiency, and avoidance of overheating sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

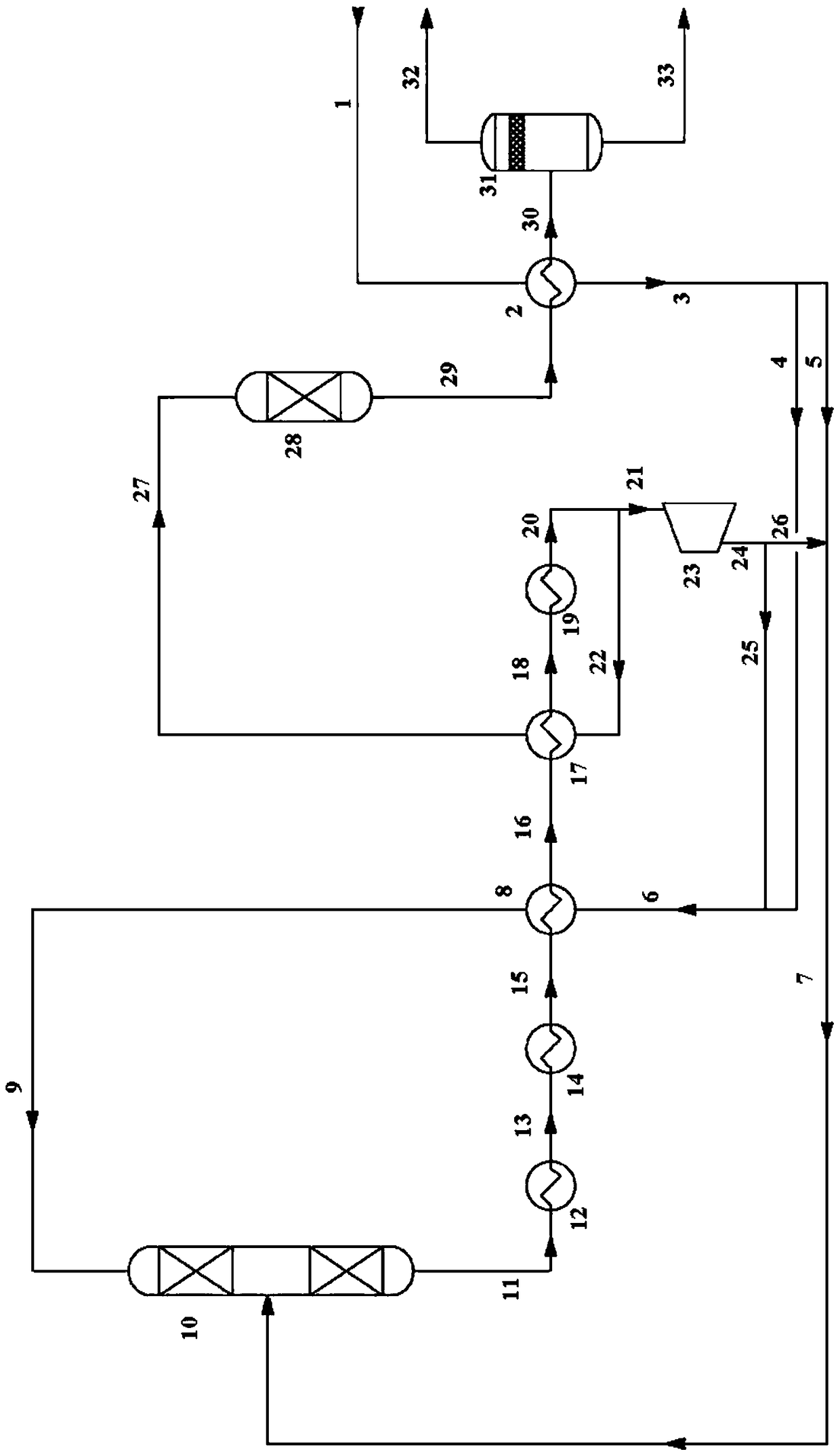

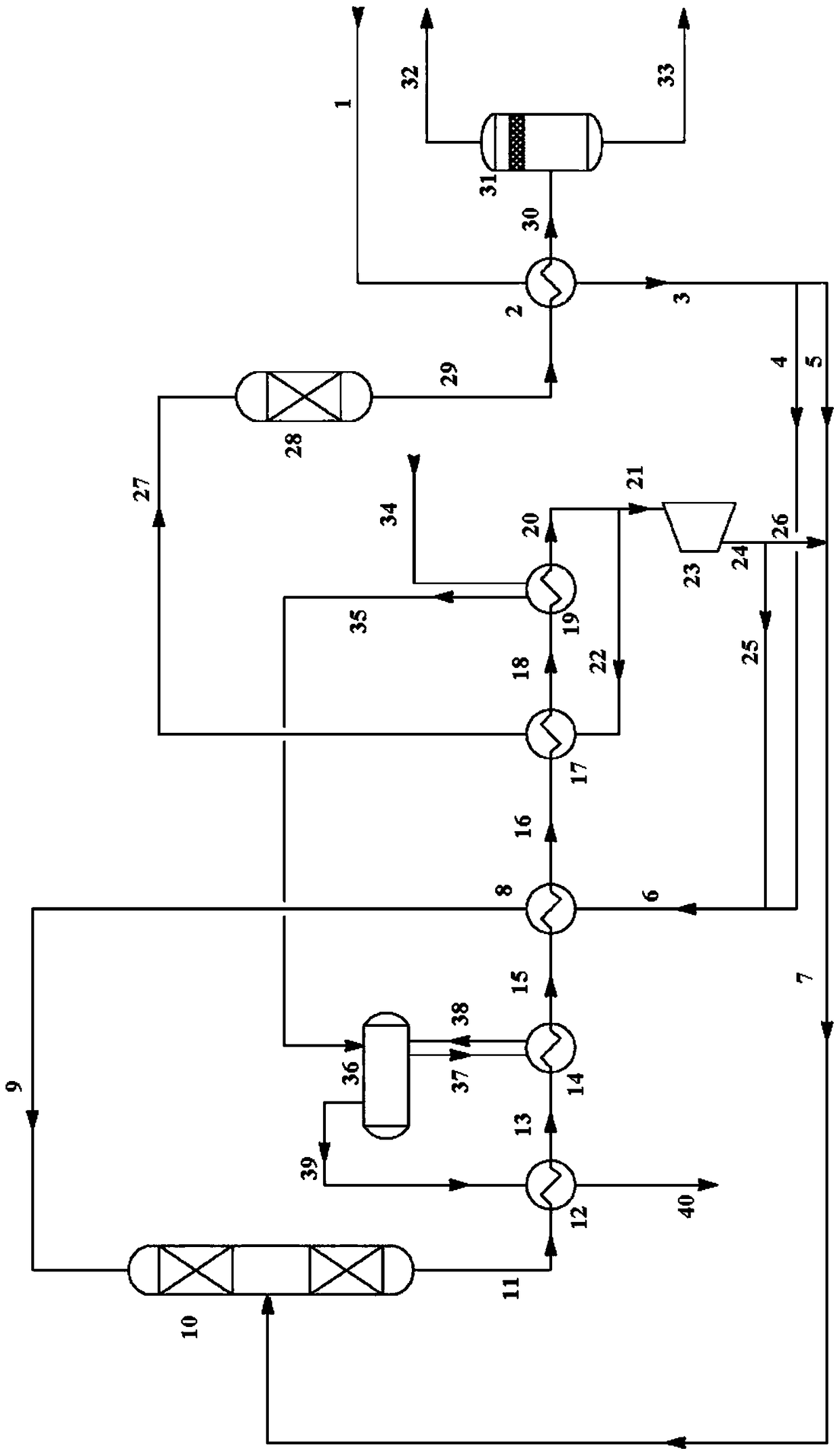

[0062] This example is used to illustrate a preferred implementation of the method for producing synthetic natural gas provided by the present invention. Specifically, such as figure 1 with figure 2 As shown, the method includes the following steps:

[0063] a) Raw material gas 1 is heated to 180-200°C through the first heat exchange equipment 2 to obtain heated raw material gas 3, and the heated raw material gas 3 is divided into the first raw material gas 4 and the second raw material gas according to the volume ratio of 1:0.25 Share raw gas 5;

[0064] b) Mix the first feed gas 4 in step a) with the first recycle gas 25 to obtain the first mixed gas 6, and the first mixed gas 6 is heated to 260-280° C. through the second heat exchange device 8 to obtain The first mixed gas 9 after the temperature rise, the first mixed gas 9 after the temperature rise is passed into the catalyst bed layer on the top of the first methanation reactor 10 for reaction;

[0065] c) Mix the s...

Embodiment 2

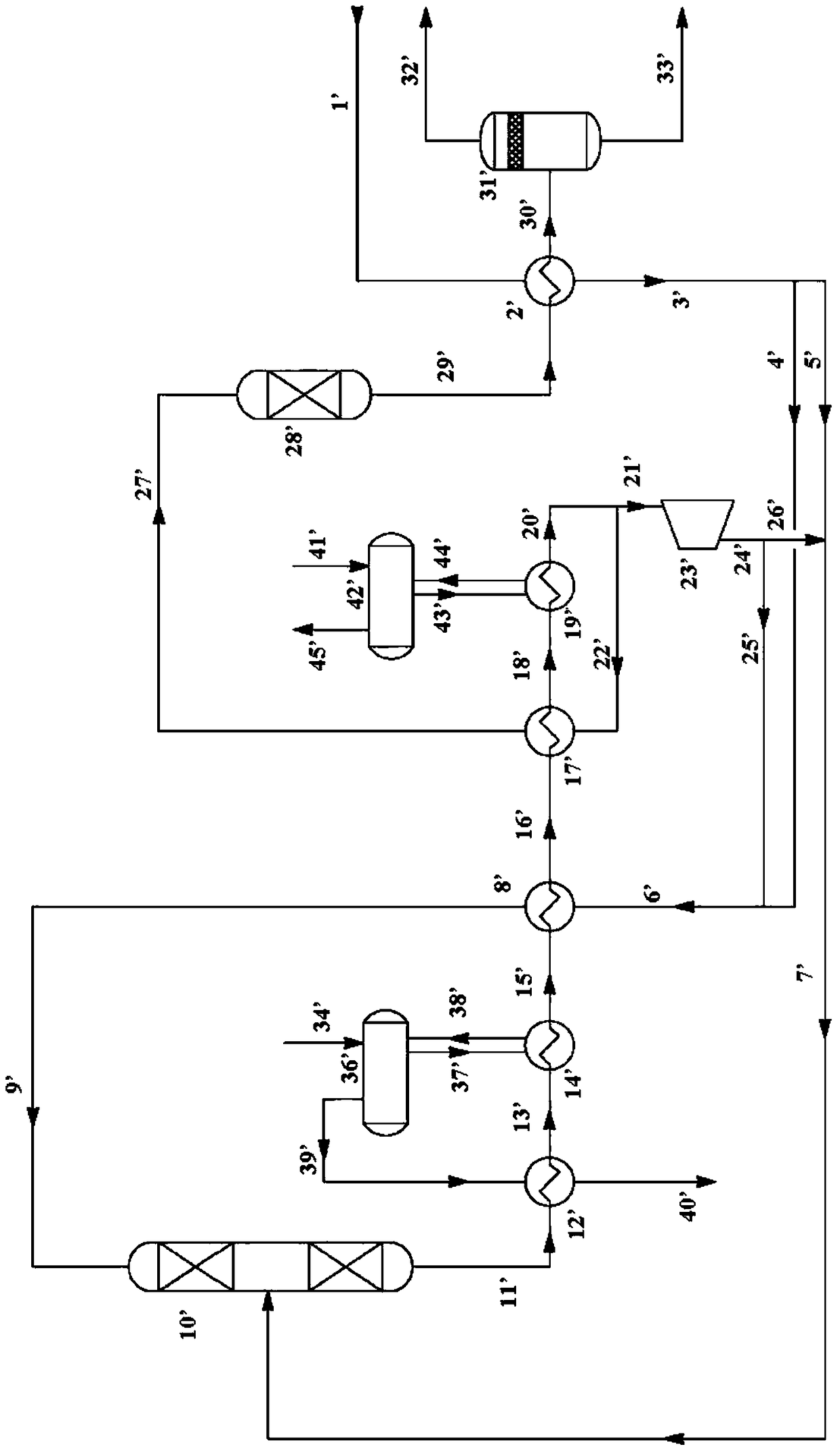

[0077] This example is used to illustrate a preferred implementation of the method for producing synthetic natural gas provided by the present invention. Specifically, such as figure 1 with image 3 As shown, the method includes the following steps:

[0078] a) Raw material gas 1 is heated to 160-180°C through the first heat exchange equipment 2 to obtain heated raw material gas 3, and the heated raw material gas 3 is divided into the first raw material gas 4 and the second raw material gas according to the volume ratio of 1:0.33 Share raw gas 5;

[0079] b) Mix the first raw material gas 4 in step a) with the first recycle gas 25 to obtain the first mixed gas 6, and the first mixed gas 6 is heated to 270-290° C. through the second heat exchange device 8 to obtain The first mixed gas 9 after the temperature rise, the first mixed gas 9 after the temperature rise is passed into the catalyst bed layer on the top of the first methanation reactor 10 for reaction;

[0080] c) Mi...

Embodiment 3

[0092] This example is used to illustrate a preferred implementation of the method for producing synthetic natural gas provided by the present invention. Specifically, such as figure 1 with figure 2 As shown, the method includes the following steps:

[0093] a) Raw material gas 1 is heated to 150-170°C through the first heat exchange equipment 2 to obtain heated raw material gas 3, and the heated raw material gas 3 is divided into the first raw material gas 4 and the second raw material gas according to the volume ratio of 1:0.3 Share raw gas 5;

[0094] b) Mix the first raw material gas 4 in step a) with the first recycle gas 25 to obtain the first mixed gas 6, and the first mixed gas 6 is heated to 290-310° C. through the second heat exchange device 8 to obtain The heated first mixed gas 9 passes the heated first mixed gas 9 into the catalyst bed on the top of the first methanation reactor 10 for reaction;

[0095] c) Mix the second feed gas 5 in step a) with the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com