Energy-saving LED warehouse lamp

An LED lamp bead and energy-saving technology, which is applied in the field of storage lights, can solve the problems of light shaking, small irradiation area, and low illumination, and achieve the effects of simplifying the structure, increasing the irradiation area, and increasing the illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

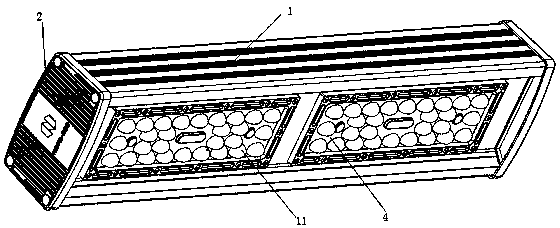

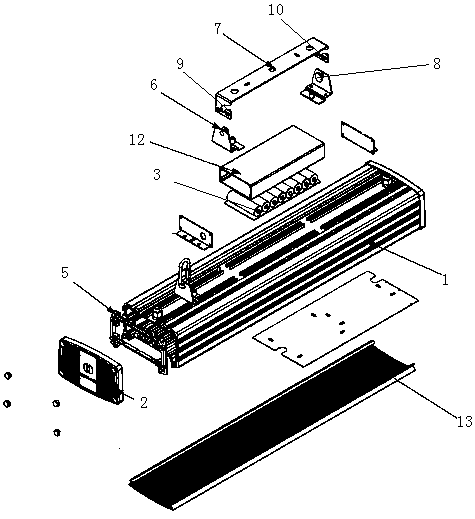

[0014] Such as Figure 1~2 As shown, an energy-saving LED storage light disclosed by the present invention includes a lamp body 1 , end covers 2 on both sides, a mounting bracket, a light source board, a driving power supply, an emergency power supply 3 and a lens 4 .

[0015] Specifically, the lamp body 1 is a cavity structure, and the two ends are sealed and fixed through the end cover 2 and the waterproof sealing ring 5. The bottom surface of the lamp body 1 has a plurality of light source openings (not shown in the figure), and the light source board is installed on the In the cavity of the lamp body, and the installation position corresponds to the light source opening, a plurality of LED lamp beads are distributed on the light source board, and when the light source board is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com