Heating radiator set assembly device

A technology for radiators and bottom plates, which is applied in the field of radiator group assembly devices, can solve problems such as wall damage and inconvenience of new radiator groups, and achieve the effects of reduced occupancy, easy portability and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

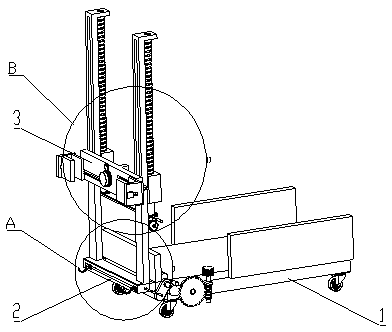

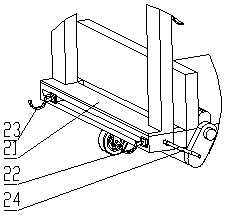

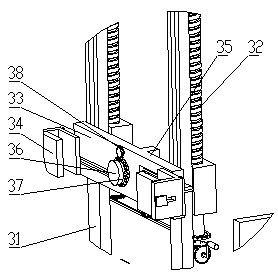

[0027] see Figure 1 to Figure 5 , the present invention provides a radiator group assembly device, including a bottom plate 1 for counterweight, loading and convenient movement, universal wheels are arranged at the bottom of the bottom plate 1, a lifting mechanism is set on the front side of the bottom plate 1, and the lifting mechanism and the bottom plate 1 Hinged, locked by pin positioning;

[0028] Baffles are vertically arranged on the two opposite outer sides of the bottom plate 1, and the distance between the two baffles of the bottom plate 1 is greater than the width of the lifting mechanism;

[0029] The lifting mechanism 2 can be placed flat on the bottom plate 1 through a hinged connection method, which is convenient for transportation. When in use, the lifting mechanism stands up and is kept vertical by the pin shaft, which is convenient for carrying the radiator group;

[0030] The lifting mechanism includes a lower support part 2 and an upper support part 3 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com