Ultrahigh vacuum low-temperature sample table

An ultra-high vacuum, sample stage technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of short-term exposure of samples to the air, changes in sample properties, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

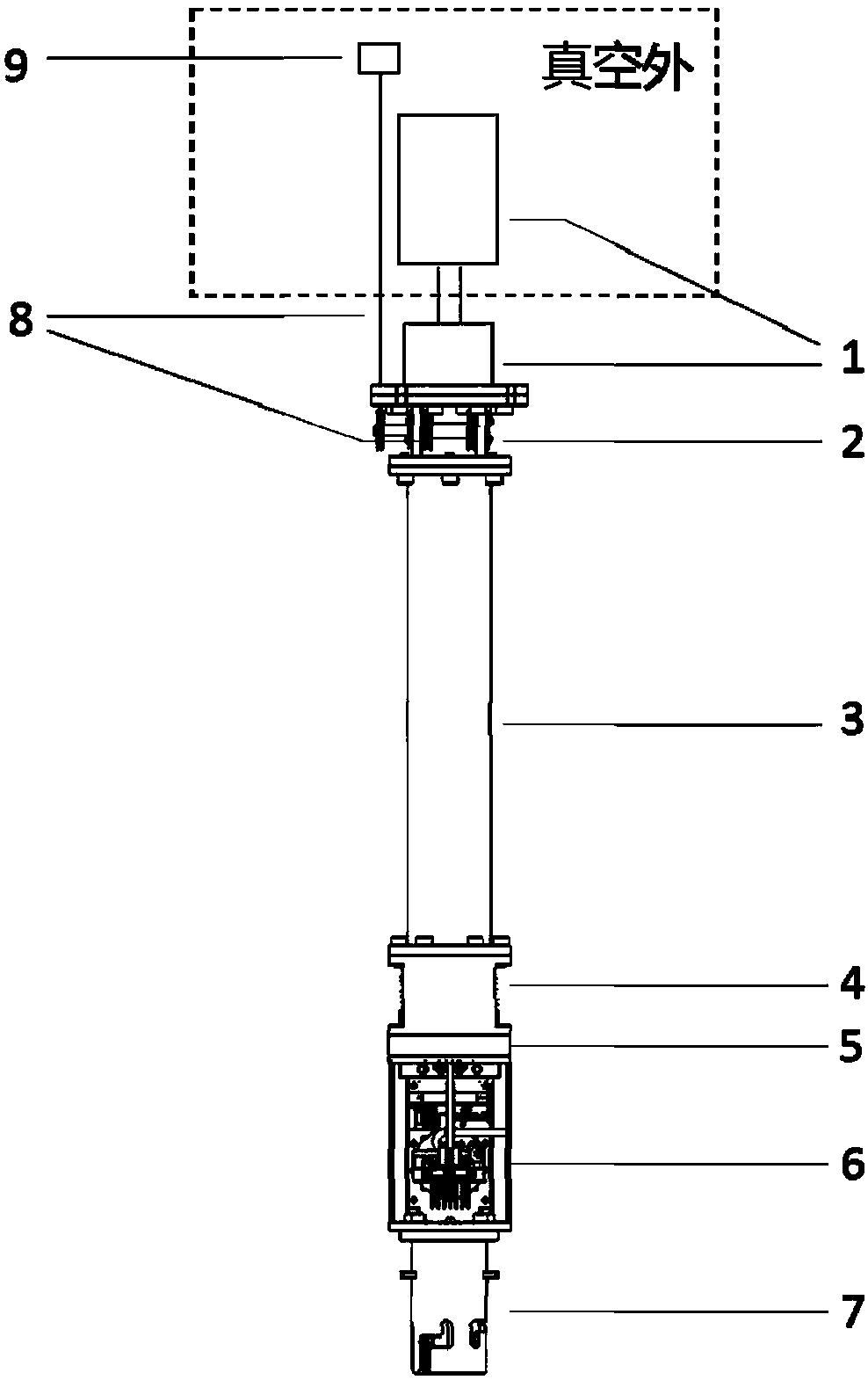

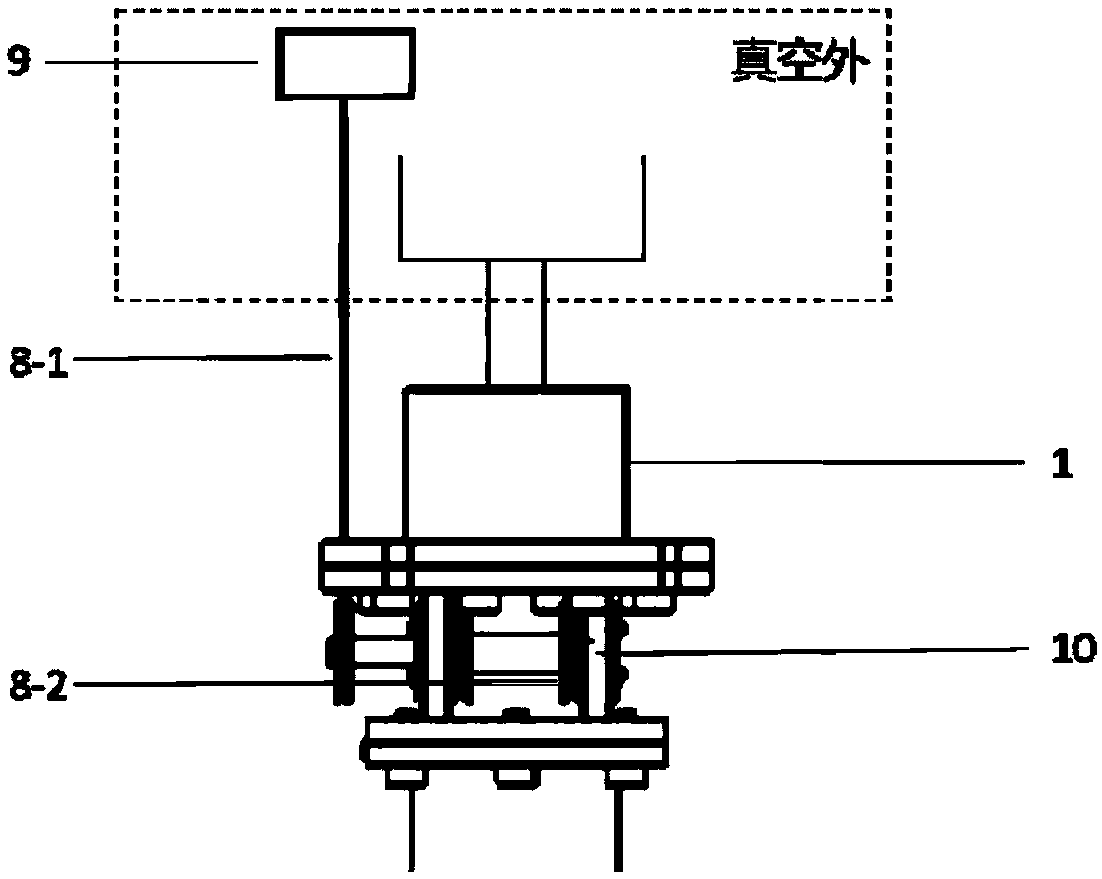

[0023] After the sample is put into the sample stage 24, the detachable shielding cover 7 is installed. On the one hand, the detachable shield 7 is used to isolate the heat radiation of the sample in the sample stage 6 from the outside; on the other hand, the movement and rotation of the sample stage 6 is completed by operating the locking structure in the detachable shield 7 .

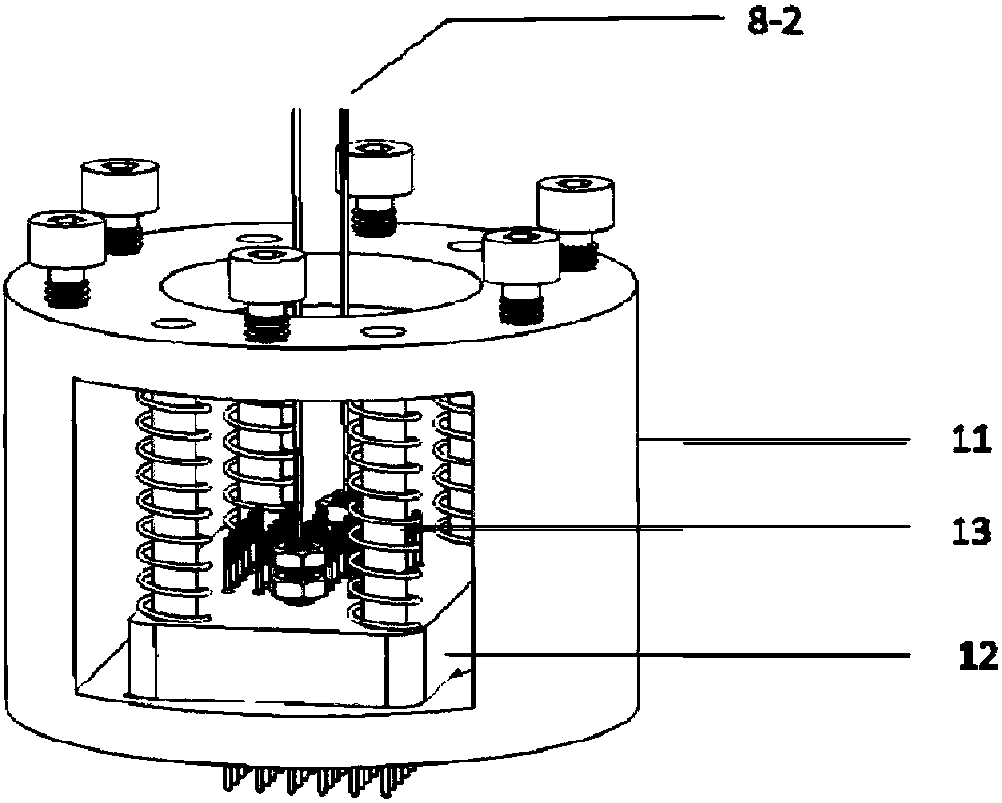

[0024] Inside the sample table body 6, the sample is fixed on the side of the sample table 24 away from the cryogenic cold head 1; the spring probe array on the probe base 25 completes the electrical connection between the sample and the probe base 25; The end of the spring probe is connected with an electric wire, and the other end of the electric wire is connected to the probe on the PAD electrode assembly 26 through the guidance of the wiring guide rod 21; one end of the copper braid group 29 is fixed on the sample stage 24 by a copper braid briquetting block 30 , the other end is fixed on the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com