A Loading and Unloading Equipment Scheduling Method Considering AGV Collision Avoidance

A collision avoidance, loading and unloading equipment technology, applied in the direction of transportation and packaging, control/adjustment system, two-dimensional position/channel control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

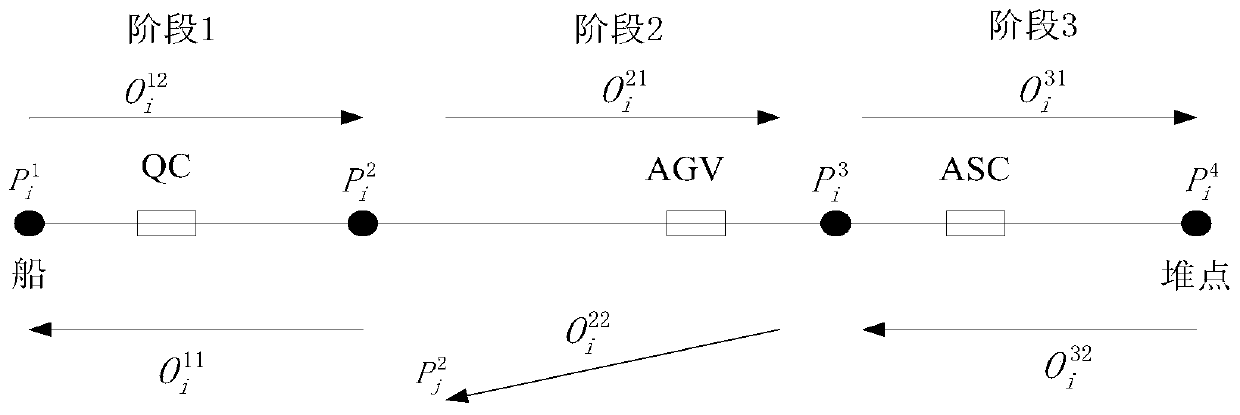

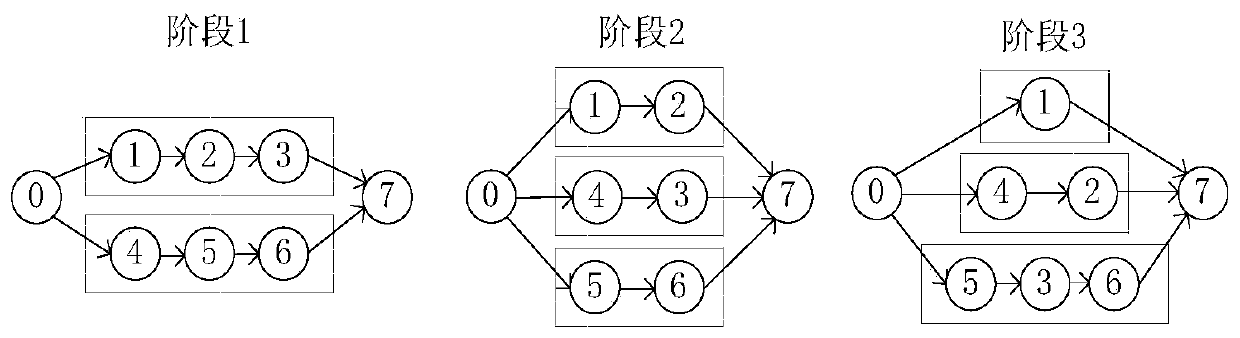

[0104] Step 1: Establish a three-stage equipment model

[0105] In the present invention, multiple QCs, multiple AGVs and multiple ASCs in an automated container terminal are considered. The operation of the three types of equipment can be regarded as a three-stage mixed flow workshop. In a mixed flow workshop, each task performed has to go through several stages of processing. The same equipment at each stage can process part of a task in parallel. The processing sequence of each task is the same and the processing time of each stage of each task is fixed. In the three-stage flow workshop, a task is defined as a complete process of transporting a container from a ship to a designated location in the storage area.

[0106] (1) Phase 1: Multiple QC

[0107] (2) Phase 2: Multiple AGVs

[0108] (3) Stage 3: Multiple ASCs

[0109] All operations of the defined three-stage mixed flow workshop are such as figure 1 Shown. P i 1 Defined as the position of container i on the ship, P i 2 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com