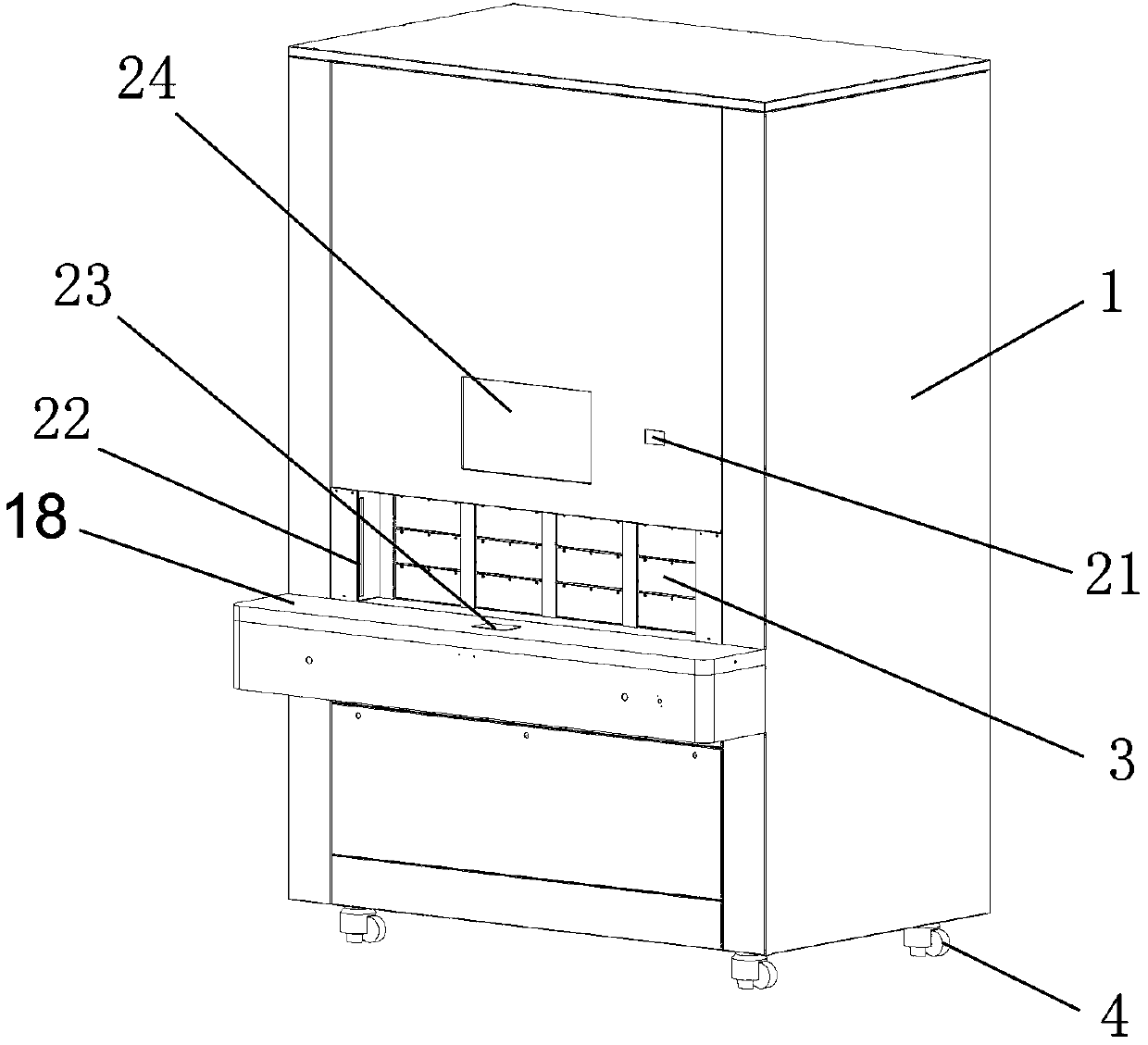

Rotating coat distributing machine

A hair dryer and rotary technology, which is applied to computer parts, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. The effect of clothing convenience, reducing labor intensity and maintaining dignity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

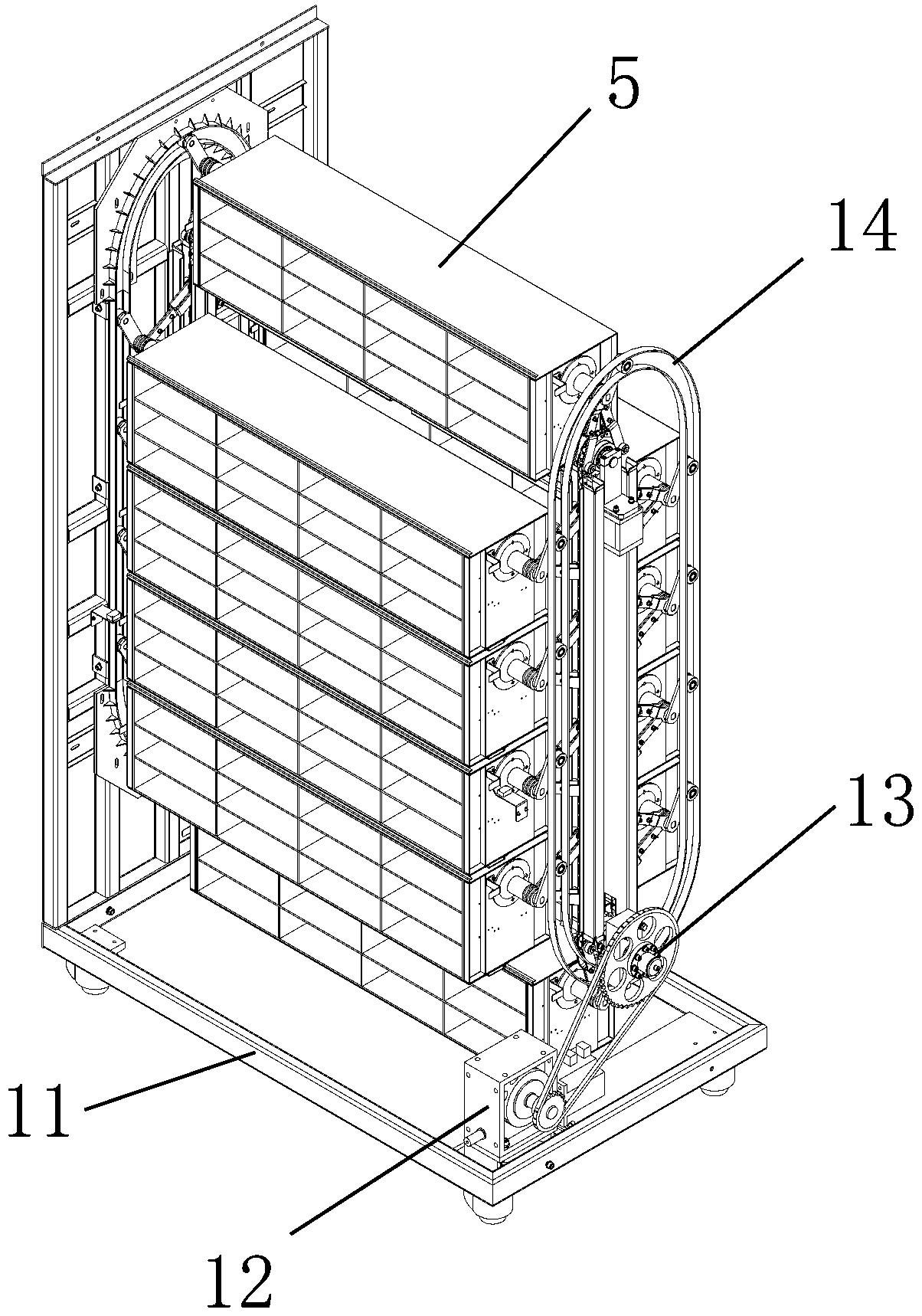

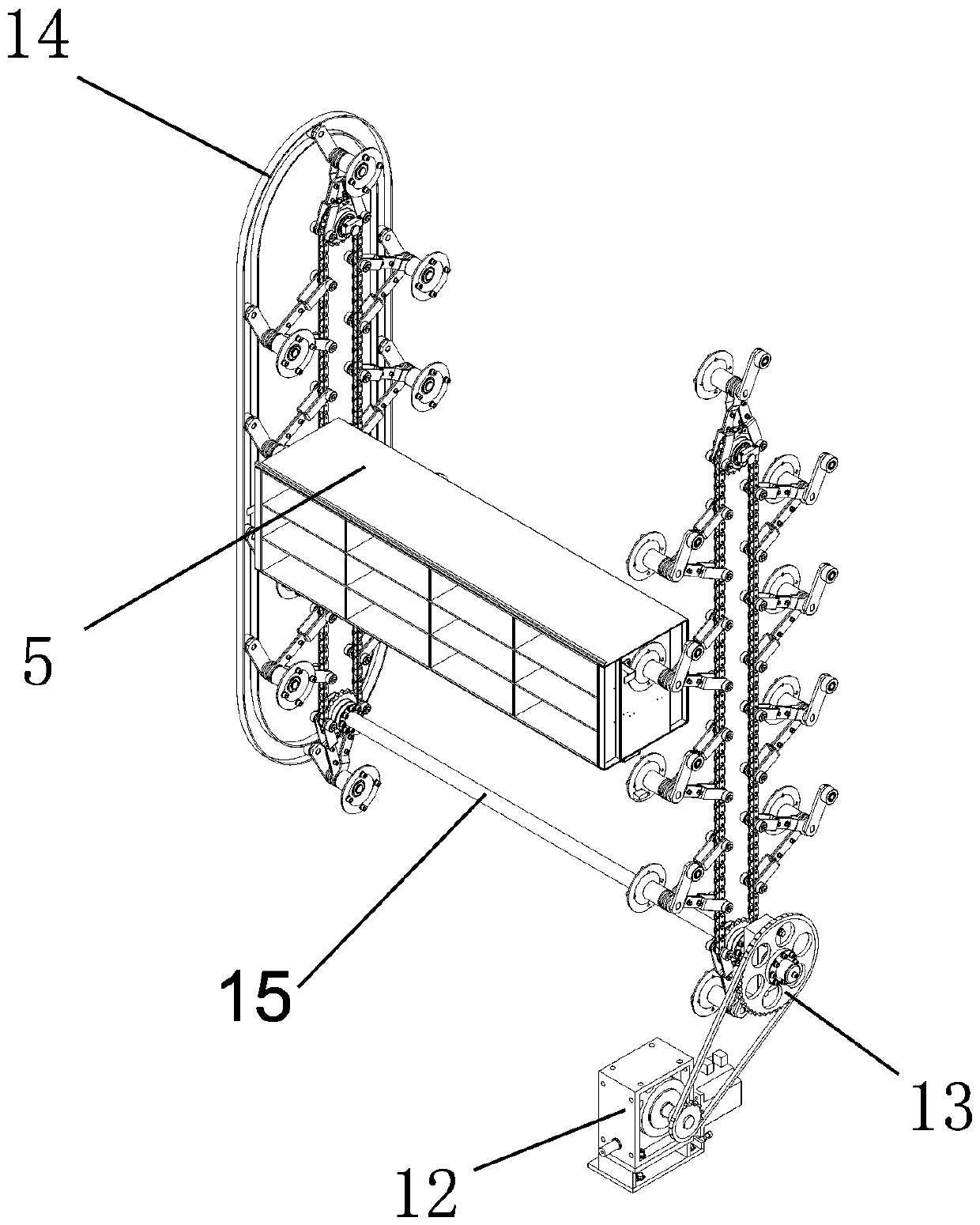

[0037] With reference to accompanying drawing, rotary hairdressing machine, comprises frame and shell, is provided with first main transmission wheel 13 below frame 11, and first main transmission wheel is connected with driving motor 12, and first main transmission wheel passes through first main transmission wheel. Chain 60 is connected with the first driven wheel 16 installed on the frame top, the second main transmission wheel is coaxially installed with the first main transmission wheel, and the second main transmission wheel is installed on the second passive wheel above the frame by the second chain. Wheel connection; between the first and second chains, several clothes bucket assemblies are fixed, and the clothes bucket assembly includes clothes bucket 5, fixed plate and connecting arm, and the two sides of the clothes bucket are respectively connected with fixed plate 6, and the outer side of the fixed plate is provided with There is an extension shaft, and two connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com