Coaxial microstrip transition device

A microstrip and coaxial technology, applied in connection devices, electrical components, circuits, etc., can solve the problems of poor high-frequency performance, poor process consistency, and low energy conversion efficiency, achieving good consistency, good microwave signal matching, Conducive to the effect of microwave signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

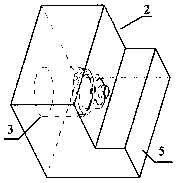

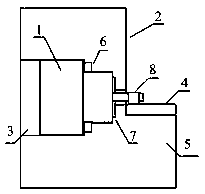

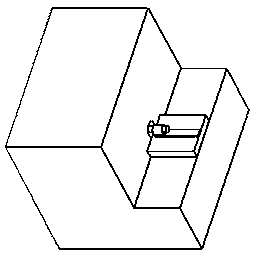

[0014] A coaxial microstrip conversion device includes: a coaxial connector 1 and a box body 2, and also includes: a solder ring 6, a cavity matching groove 7 and a gold band ring 8.

[0015] The input and output of the RF component are connected to external signals through the coaxial connector 1. There are coaxial connector mounting holes 3, cavity matching grooves 7 and solder rings 6 at the input and output positions of the RF component box body 2. The position of the mounting hole is the input of the RF component. At the output, the shape of the mounting hole matches the coaxial connector 1 used; the cavity matching groove 7 is a ring concentric with the coaxial mounting hole; the solder ring 6 is directly above the coaxial connector mounting hole 3 on the box body 2, and the shape It is the same as the installation hole 3 of the coaxial connector, and is 1mm larger than the installation hole 3 of the coaxial connector. A microstrip substrate installation surface 5 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com