Power transmission line deicing device propelled along spiral trajectory

A technology for transmission lines and transmission lines, which is applied in the installation of cables, overhead installation, electrical components, etc. It can solve problems such as short circuit, insulator string inclination, and difficulty in achieving the expected effect, and achieve the effect of avoiding damage and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

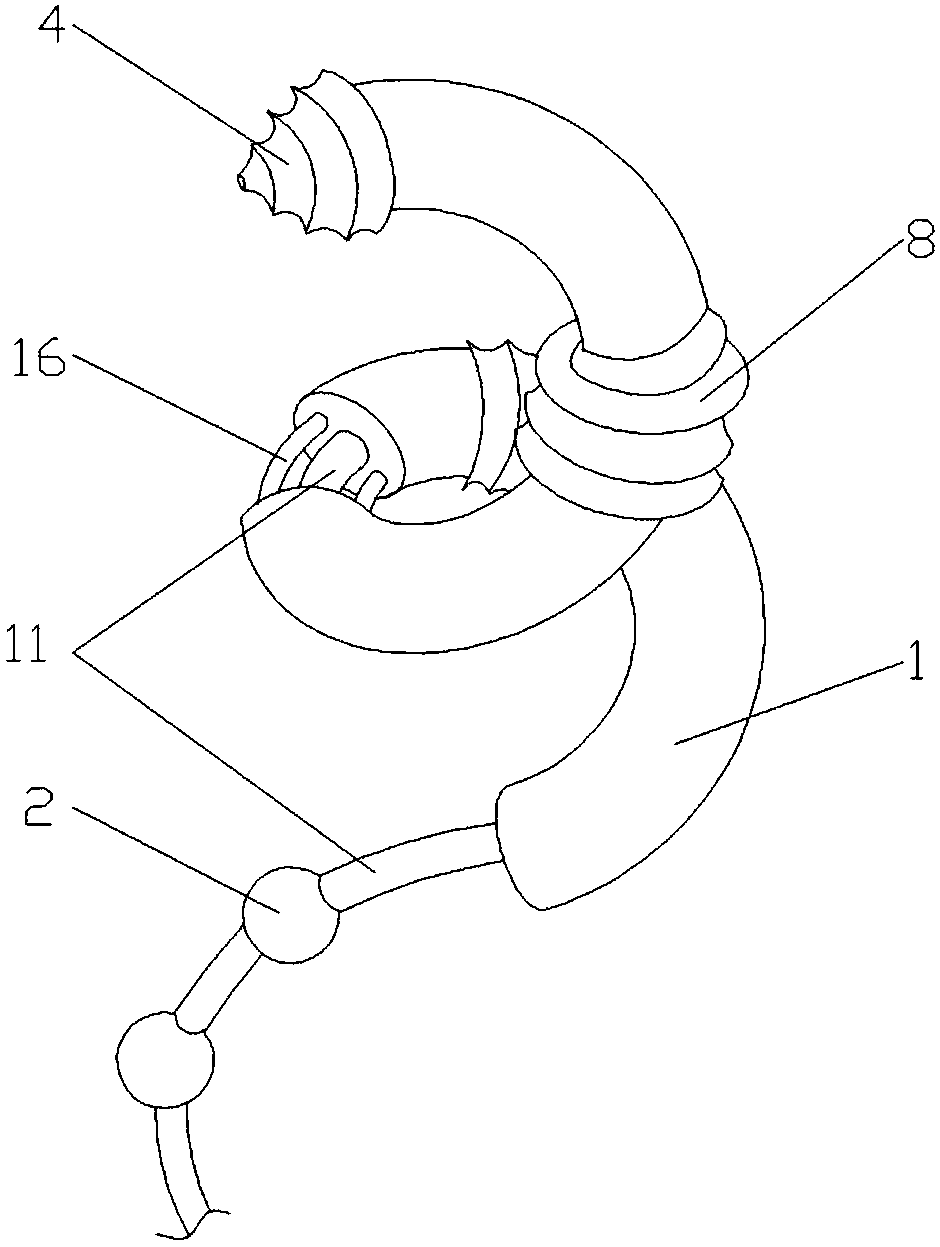

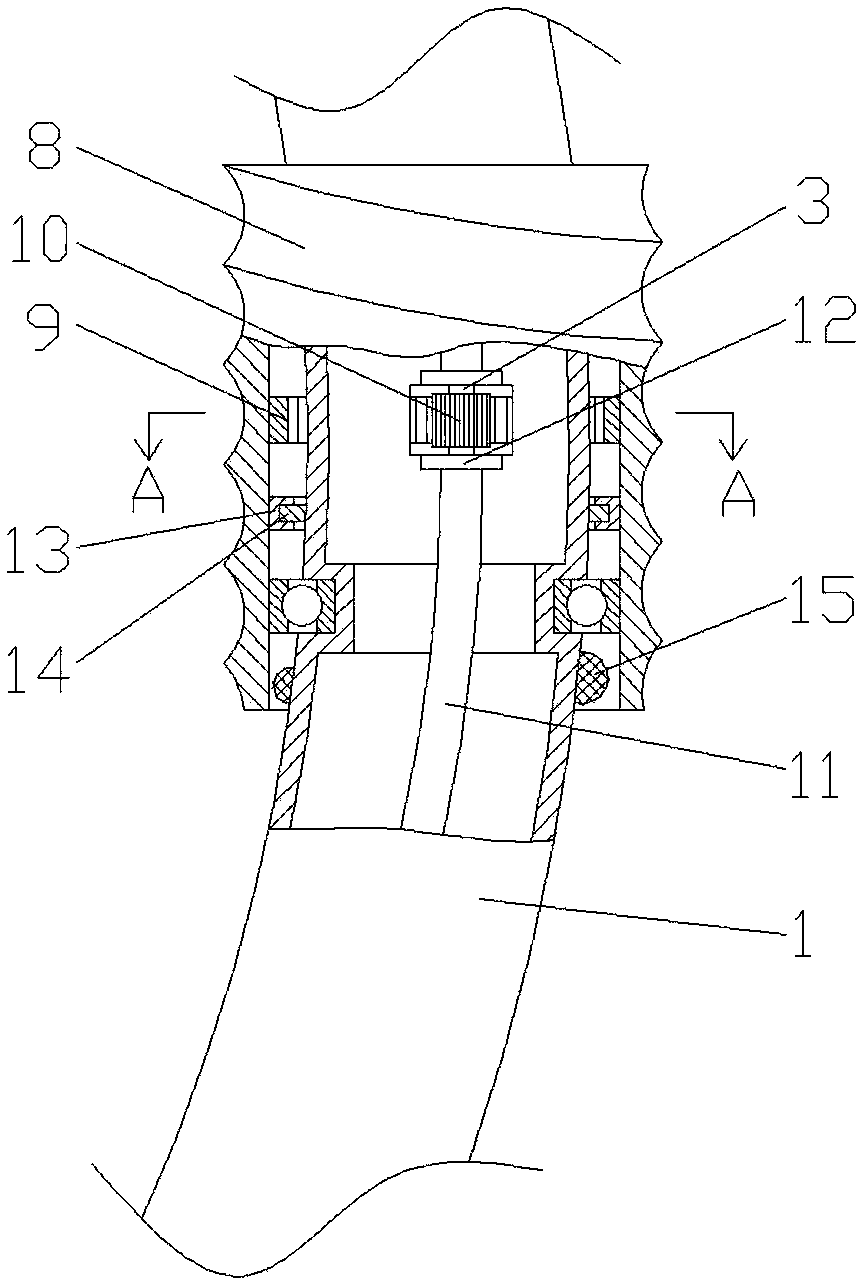

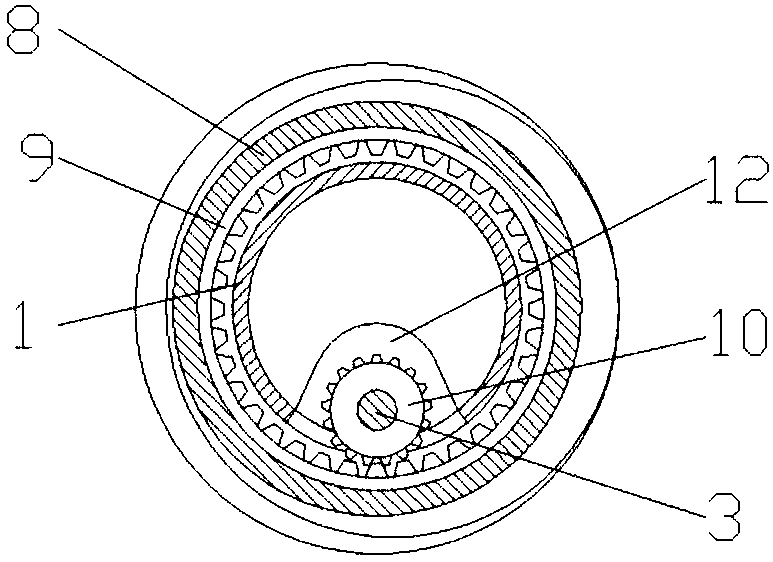

[0028] Specific embodiment 1, such as Figure 1 to Figure 4 As shown, the present invention is a power transmission line deicing device propelled along a spiral trajectory, which is used to remove the ice layer around the power transmission line. The device includes a device body 1, a blasting body 2 arranged at the tail of the device body 1, and the device The main body 1 is helical, and the head of the device main body 1 is also provided with a drill bit 4, and the device main body 1 has the degree of freedom to rotate around the axis of the transmission line by means of the drill bit 4 and the driving mechanism. The present invention is driven by the transmission shaft 3 during work, and the section of the ice layer is cleaned out by personnel on the ice-coated transmission line before use, and then the deicing device of the present invention is wound and arranged on the cleaned-up transmission line, and the drill bit is used to remove the ice. Holes are drilled in the ice-...

specific Embodiment 2

[0031] Specific embodiment 2, described drill bit comprises the drill bit 4 that is the conical structure that is connected with transmission shaft 3, is arranged on the connection structure between drill bit 4 and device body 1, and drill bit 4 has around device body 1 by means of this connection structure. The degree of freedom of axis rotation, the connection structure includes a locking ring 5 fixed to the bottom of the drill bit 4, a positioning ring 6 is clamped between the locking ring 5 and the bottom surface of the drill bit 4, and the positioning ring 6 is set Fixed on the outer wall of the device body 1, the positioning ring 6 forms rolling contact with the bottom surface of the drill bit 4 and the ring surface of the locking ring 5 by means of balls 7 respectively. The transmission shaft 3 drives the drill bit 4 to work. When the drill bit 4 advances with the device body 1, the rolling connection of the balls on the positioning ring 6 reduces the resistance and faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com