Method of sealing half-hull lift stern shaft hole or sea chest

A subsea valve box and stern shaft technology, applied in ship parts, ship construction, ship design, etc., can solve the problems of stern shaft hole casting or outer bottom plate damage, low on-site construction efficiency, and large carbon planing and grinding workload. Achieve the effect of reducing welding workload, reducing carbon planing and grinding workload, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

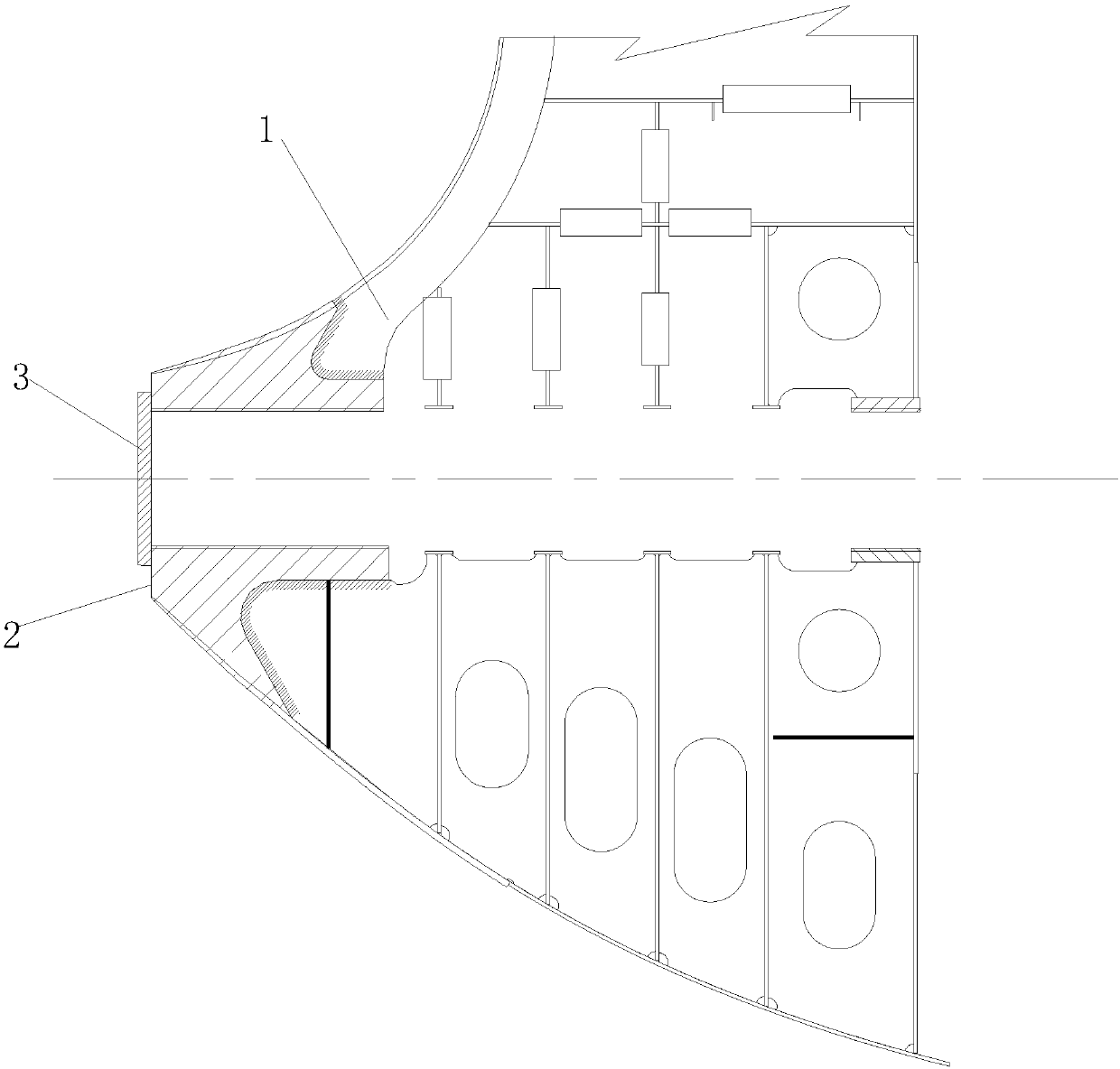

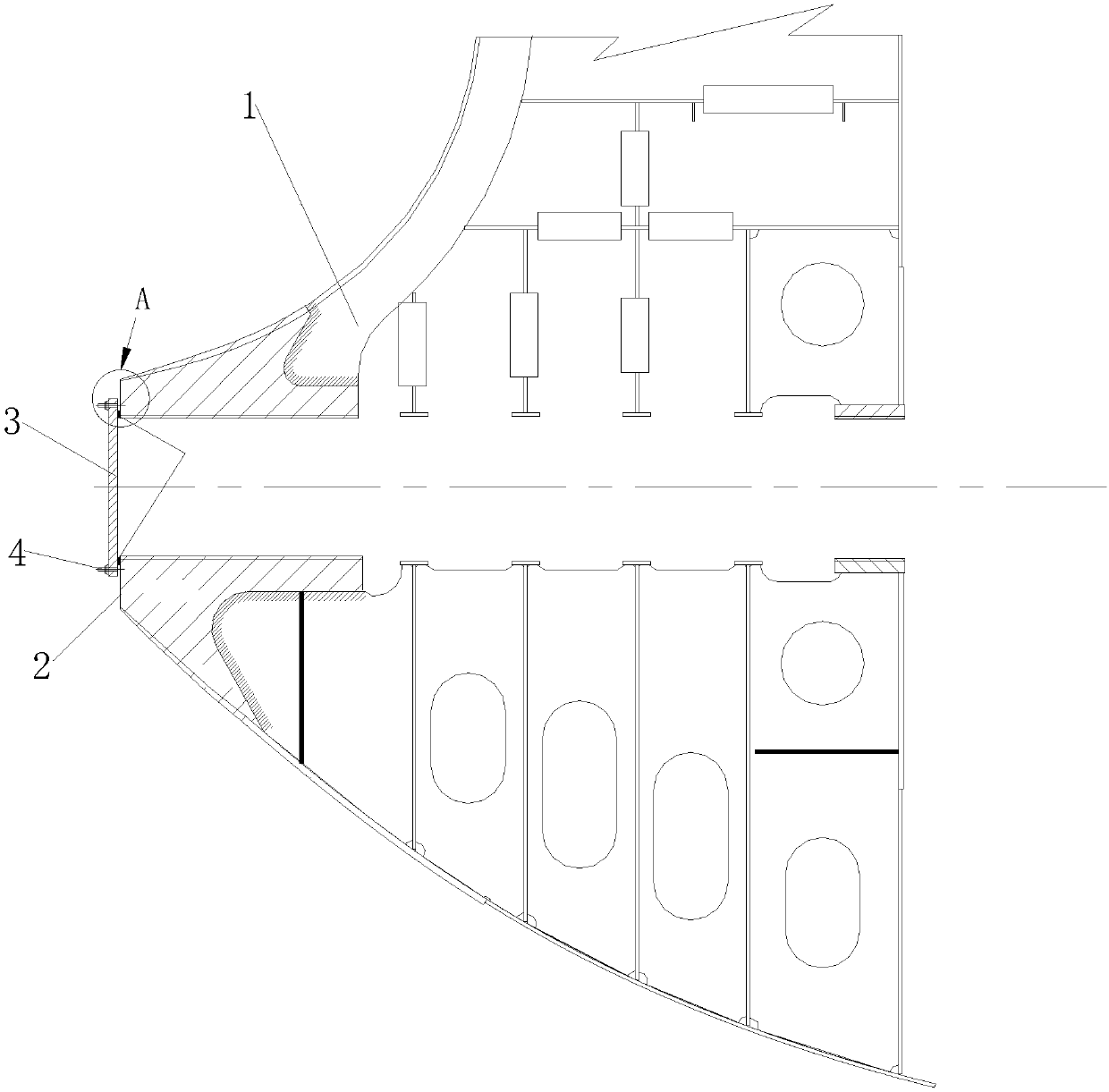

[0025] Such as figure 2 , 3 As shown, the present embodiment provides a half-ship floating stern shaft hole or seabed valve box sealing test sealing method, including the following steps:

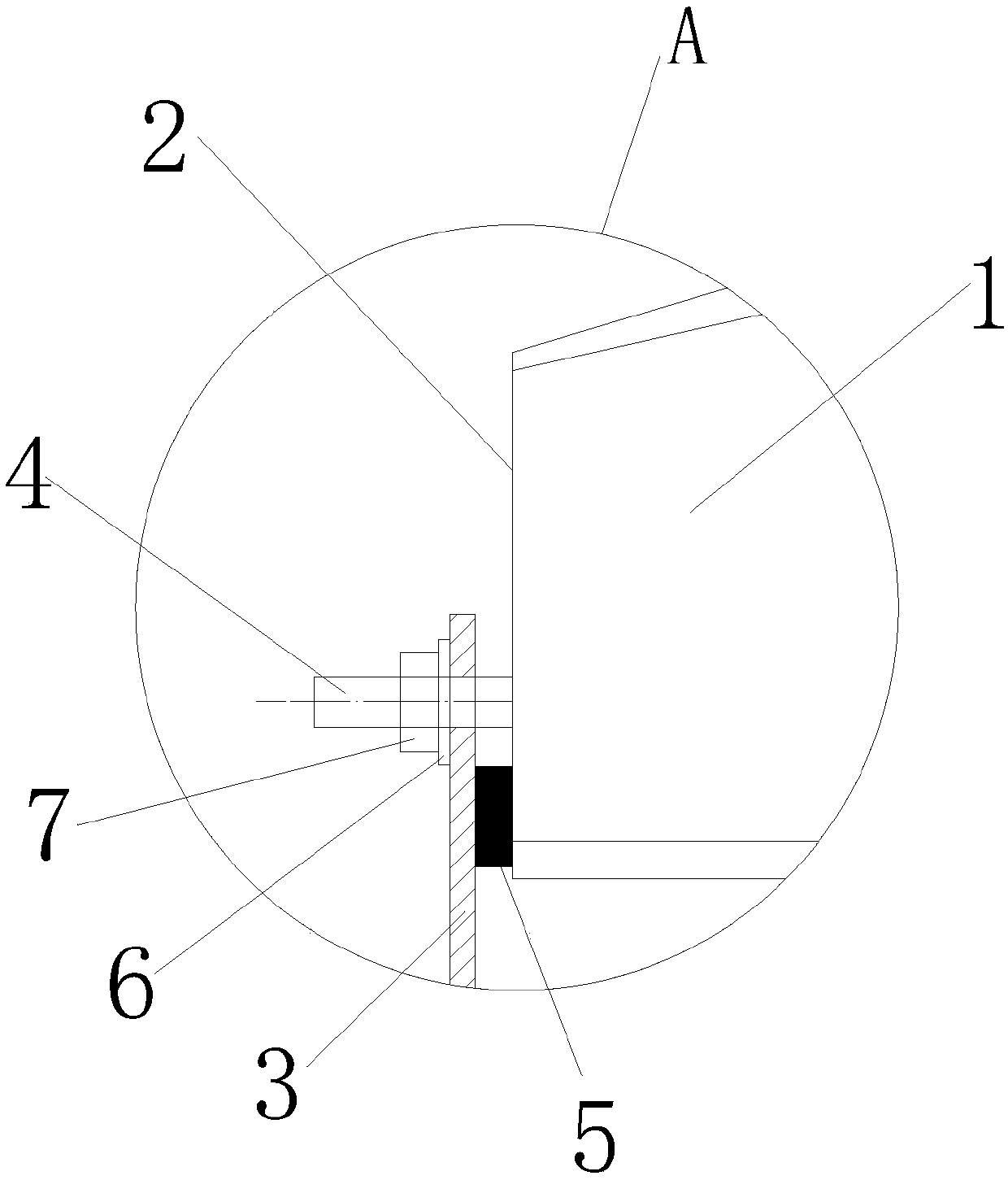

[0026] 1) Mark lines for installing bolts on the rear end surface 2 of the stern shaft hole or the outer bottom plate of the seabed valve box, and install several screw rods 4 according to the positions of the marked lines;

[0027] Preferably, the screw rod 4 is welded and fixed on the rear end surface 2 of the tail shaft hole or the outer bottom plate of the sea bottom valve box by stud welding to ensure the reliability of the connection.

[0028] 2) Select steel plate blanking to make the plugging plate 3 for plugging the stern shaft hole or the seabed valve box, and provide bolt holes corresponding to the screw rod 4 on the outer periphery of the plugging plate 3;

[0029] 3) Marking lines are drawn on the plugging plate 3 according to the size of the aperture of the stern shaft hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com