Special cable winding equipment

A technology for equipment and cables, applied in the field of special cable winding equipment, can solve the problems of high labor intensity, time-consuming and laborious manual winding of cables, slow winding speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

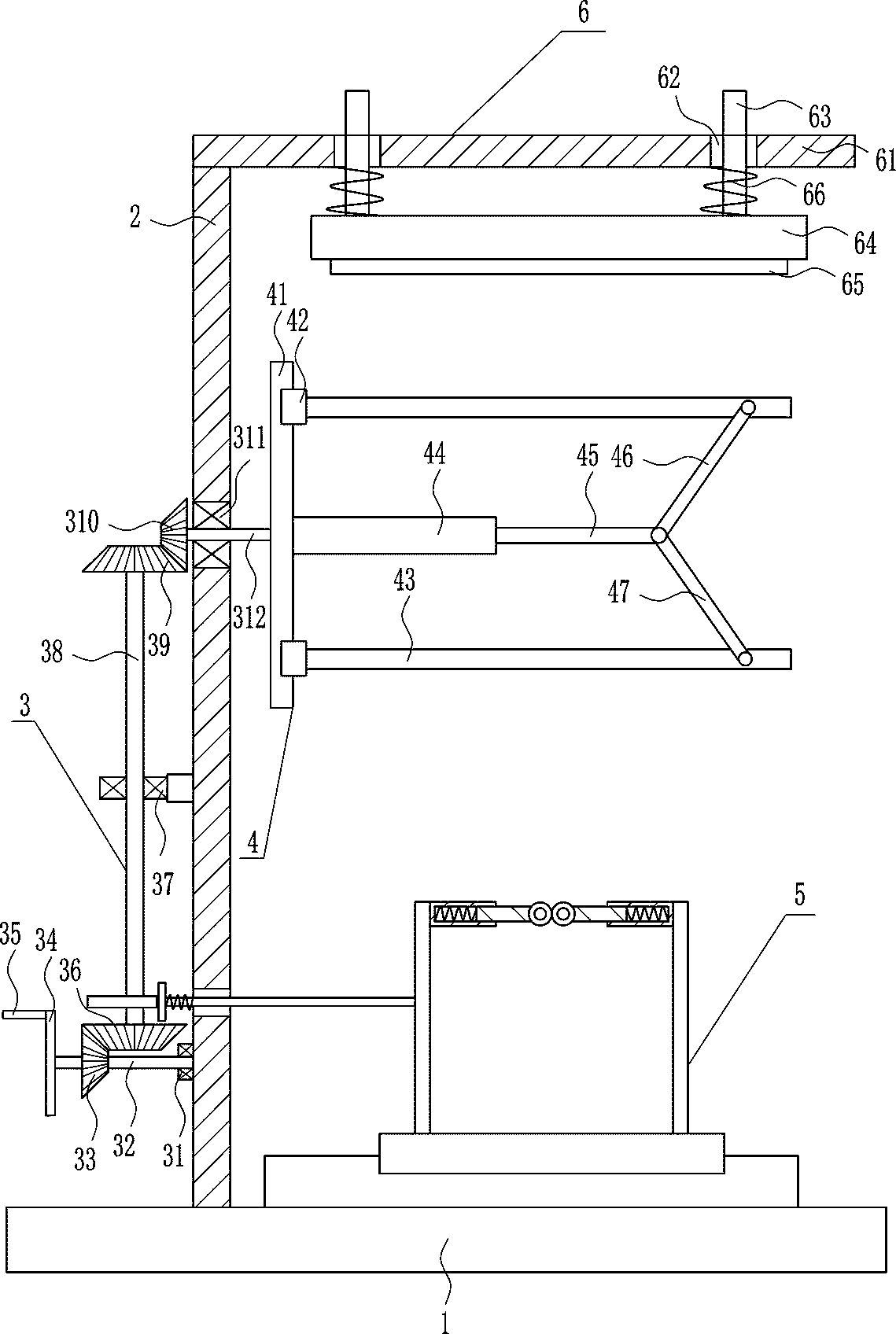

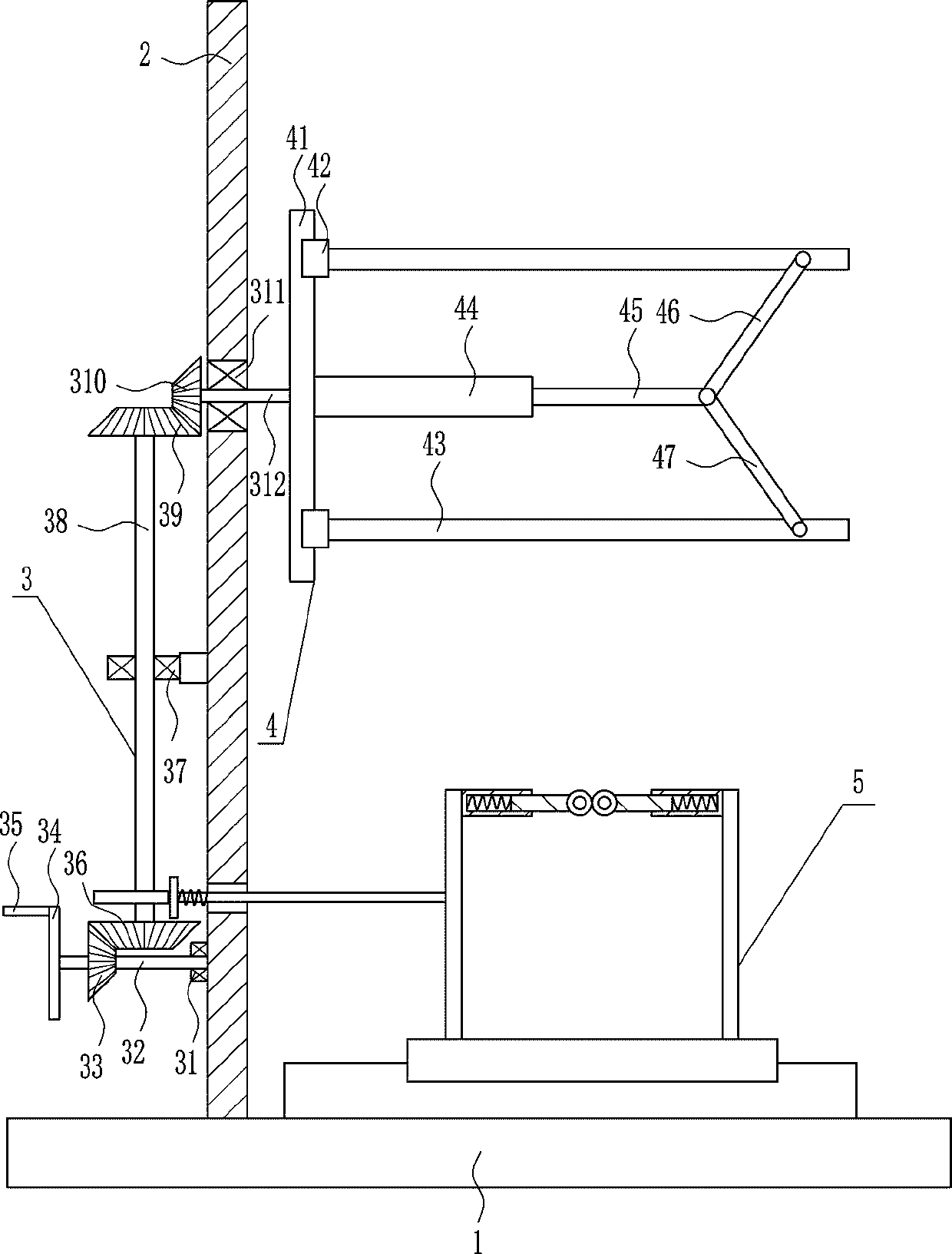

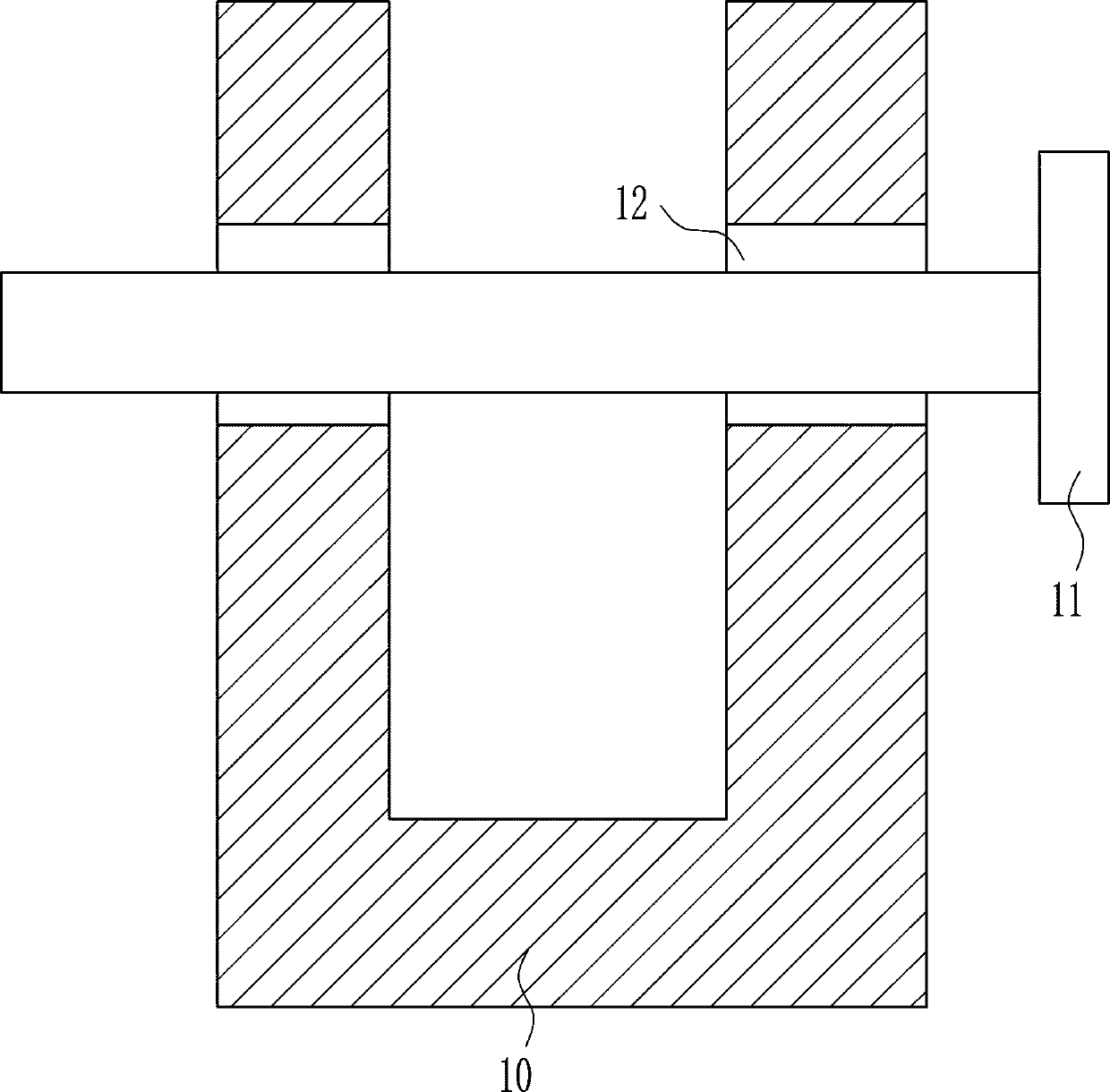

[0038] A special winding equipment for cables, such as Figure 1-8 As shown, it includes a base plate 1, a bracket 2, a rotating device 3 and a fixing device 4. The left side of the top of the base plate 1 is connected with a bracket 2 by means of bolt connection, and the left side of the bracket 2 is provided with a rotating device 3. The rotation of the rotating device 3 A fixing device 4 is arranged on the component, and the fixing device 4 is located on the right side of the bracket 2 .

Embodiment 2

[0040] A special winding equipment for cables, such as Figure 1-8 As shown, it includes a base plate 1, a bracket 2, a rotating device 3 and a fixing device 4. The left side of the top of the base plate 1 is connected with a bracket 2 by means of bolt connection, and the left side of the bracket 2 is provided with a rotating device 3. The rotation of the rotating device 3 A fixing device 4 is arranged on the component, and the fixing device 4 is located on the right side of the bracket 2 .

[0041] The rotating device 3 includes a first bearing seat 31, a first rotating shaft 32, a first bevel gear 33, a turntable 34, a handle 35, a second bevel gear 36, a second bearing seat 37, a second rotating shaft 38, and a third bevel gear 39 , the fourth bevel gear 310, the third bearing seat 311 and the third rotating shaft 312, the lower part of the left side of the bracket 2 is installed with the first bearing seat 31 by bolt connection, and the bearings in the first bearing seat 3...

Embodiment 3

[0043] A special winding equipment for cables, such as Figure 1-8 As shown, it includes a base plate 1, a bracket 2, a rotating device 3 and a fixing device 4. The left side of the top of the base plate 1 is connected with a bracket 2 by means of bolt connection, and the left side of the bracket 2 is provided with a rotating device 3. The rotation of the rotating device 3 A fixing device 4 is arranged on the component, and the fixing device 4 is located on the right side of the bracket 2 .

[0044] The rotating device 3 includes a first bearing seat 31, a first rotating shaft 32, a first bevel gear 33, a turntable 34, a handle 35, a second bevel gear 36, a second bearing seat 37, a second rotating shaft 38, and a third bevel gear 39 , the fourth bevel gear 310, the third bearing seat 311 and the third rotating shaft 312, the lower part of the left side of the bracket 2 is installed with the first bearing seat 31 by bolt connection, and the bearings in the first bearing seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com