Fabricated steel structural self-restoring energy consuming supporting device

An energy-consuming support and energy-consuming device technology, applied in building components, protective buildings/shelters, building types, etc., can solve the problems of high repair cost, large cable deformation, inconvenient construction, etc., to reduce the construction period, The effect of reducing residual deformation and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and using embodiments as examples:

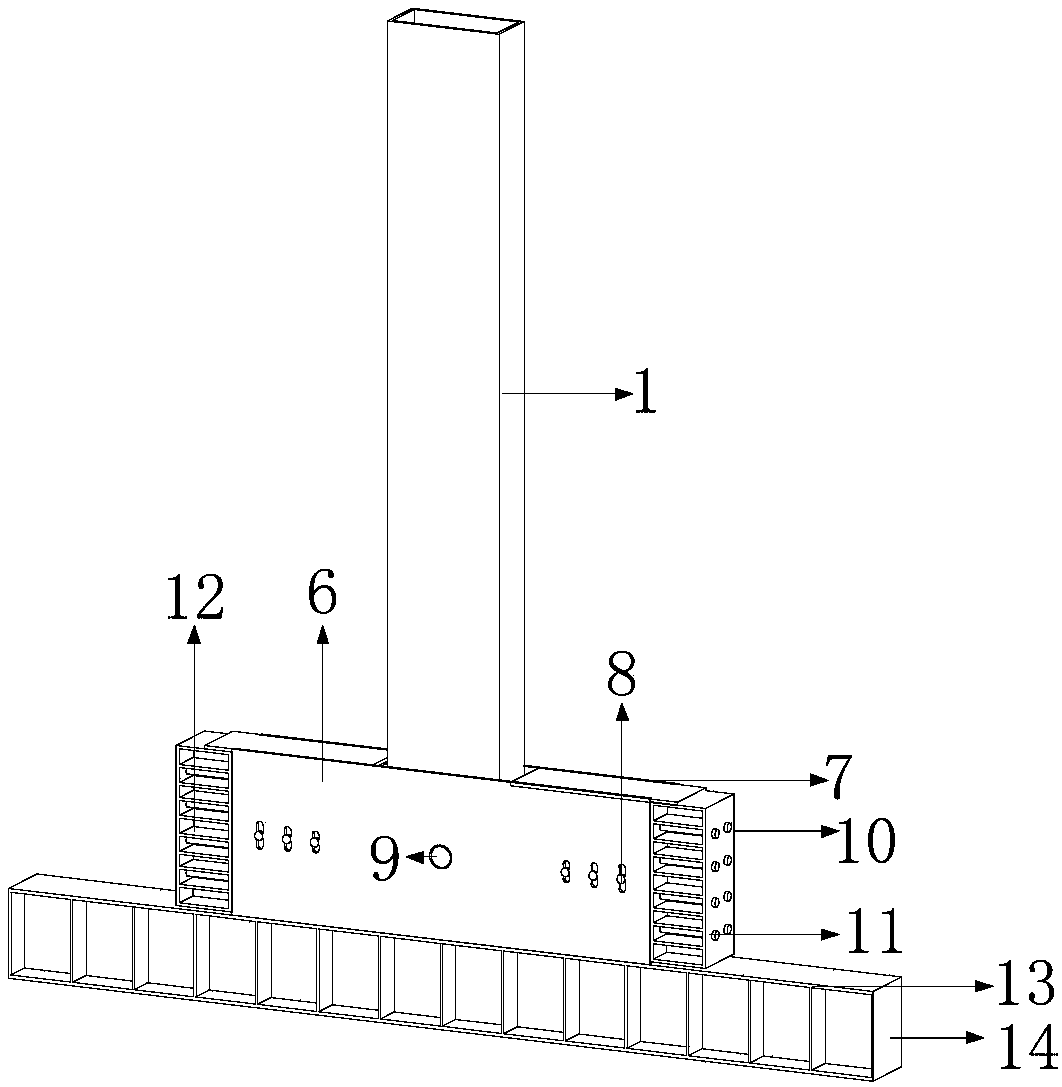

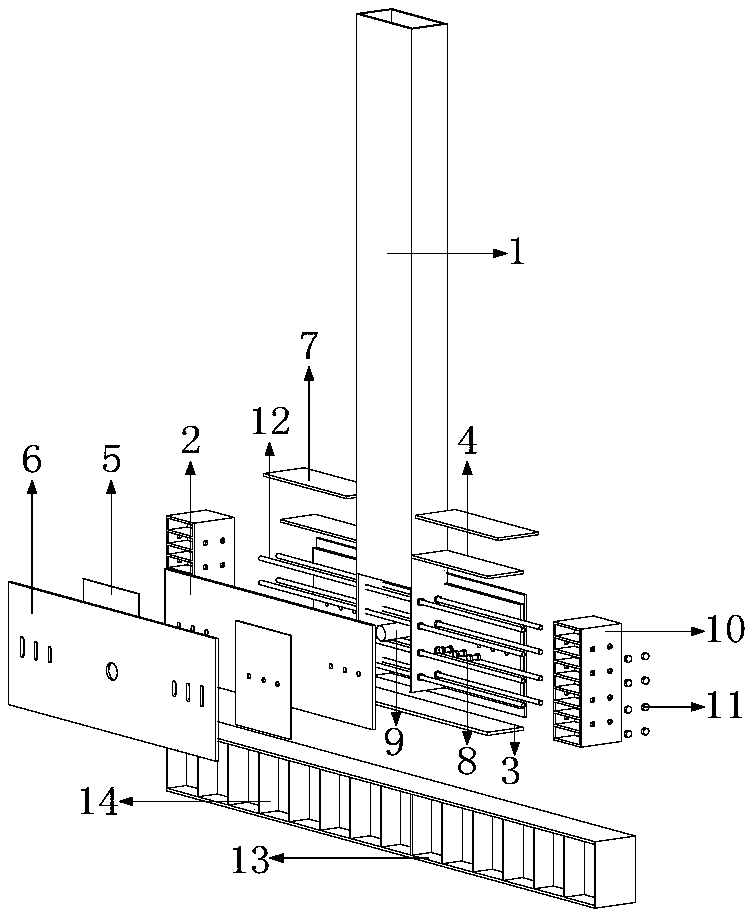

[0024] As attached figure 1 , 2 As shown, the assembly process of the present invention can be completed in the factory. In the factory, the energy-consuming system is spliced and then welded to the base steel beam. The self-resetting system is assembled in the energy-consuming system, and the tension cable is anchored with anchors. After that, the support processing is completed. Just connect the column and frame beam on site.

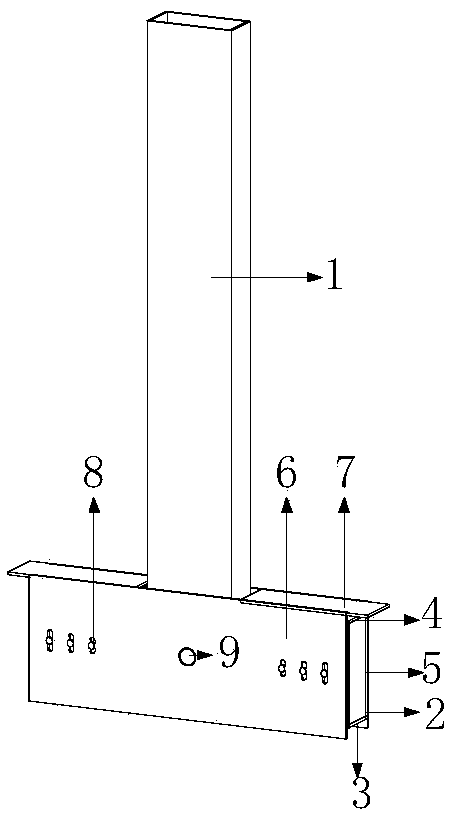

[0025] As attached image 3 , 4 As shown, the energy-consuming system of the present invention is completed in the factory during the splicing process. The cross-section of the column is square, and the short side of the bottom is provided with holes, and the two long sides are connected to the steel plate I by welding; Bolt holes and pin holes, the long cover plate is welded to the lower part of the steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com