Internal spline expansion sleeve structure for measuring jumping of speed reducers

An internal spline and reducer technology, applied in the field of reducer runout measurement, can solve the problems of inconvenient operation, complex structure, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

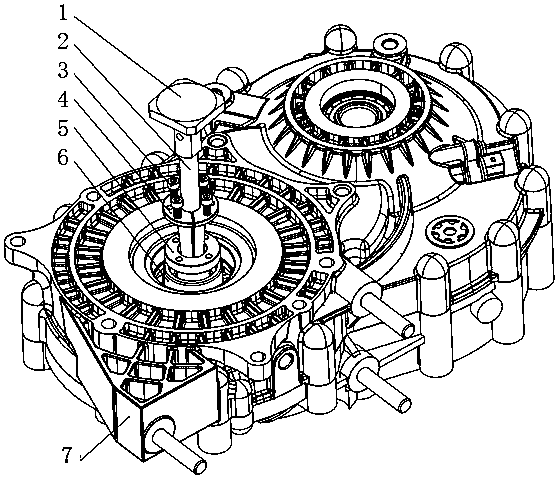

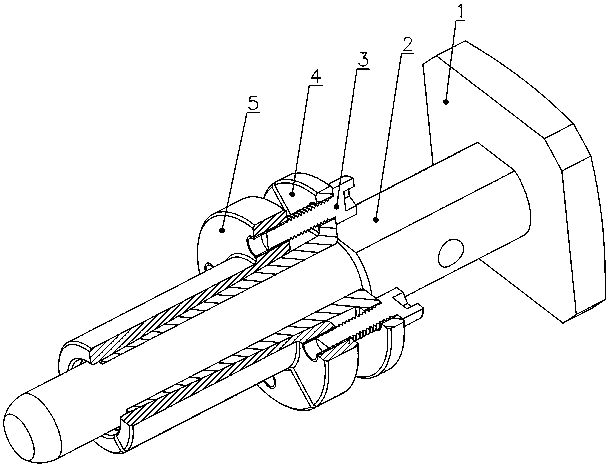

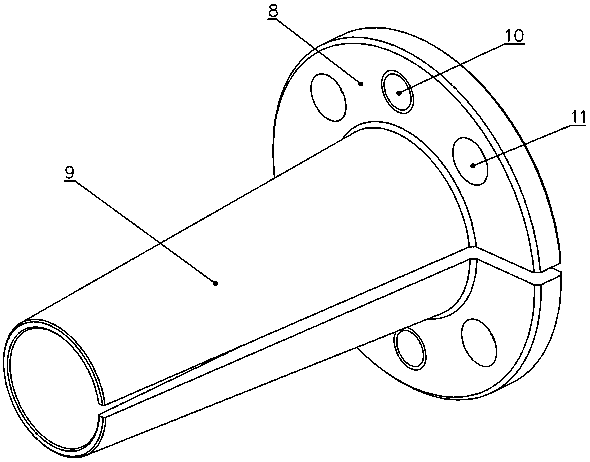

[0021] Such as figure 1 and 2 As shown, the structure of the inner spline expansion sleeve for measuring the runout of the reducer of the present invention includes a suction cup 1 , a shaft 2 , a bolt 3 , an inner ring 4 and an outer ring 5 . Such as image 3 As shown, the inner ring 4 includes an inner ring flange 8 and an inner ring taper 9 fixedly connected to one side thereof, and the inner ring flange 8 is provided with a threaded hole for disassembly 10 and an inner ring installation hole 11; as Figure 4 As shown, the outer ring 5 includes an outer ring flange 12 and an outer ring taper hole 13 fixedly connected to one side thereof, and the outer ring flange 12 is provided with an outer ring mounting hole 14 .

[0022] During specific installation, such as figure 1 and 2 As shown, the outer ring 5 and the inner spline 6 of the reducer 7 were originally in a clearance fit, first put the outer ring into the inner spline 6, then install the inner ring 4 and the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com