Non-woven funnel for compressing a fiber non-woven, having a guiding element

A technology of non-woven fabrics and guiding elements, which is applied in the directions of fiber processing, textiles and papermaking, and drafting equipment, can solve the problems such as the quality decline of fiber belts, and achieve the effect of improving quality and introduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

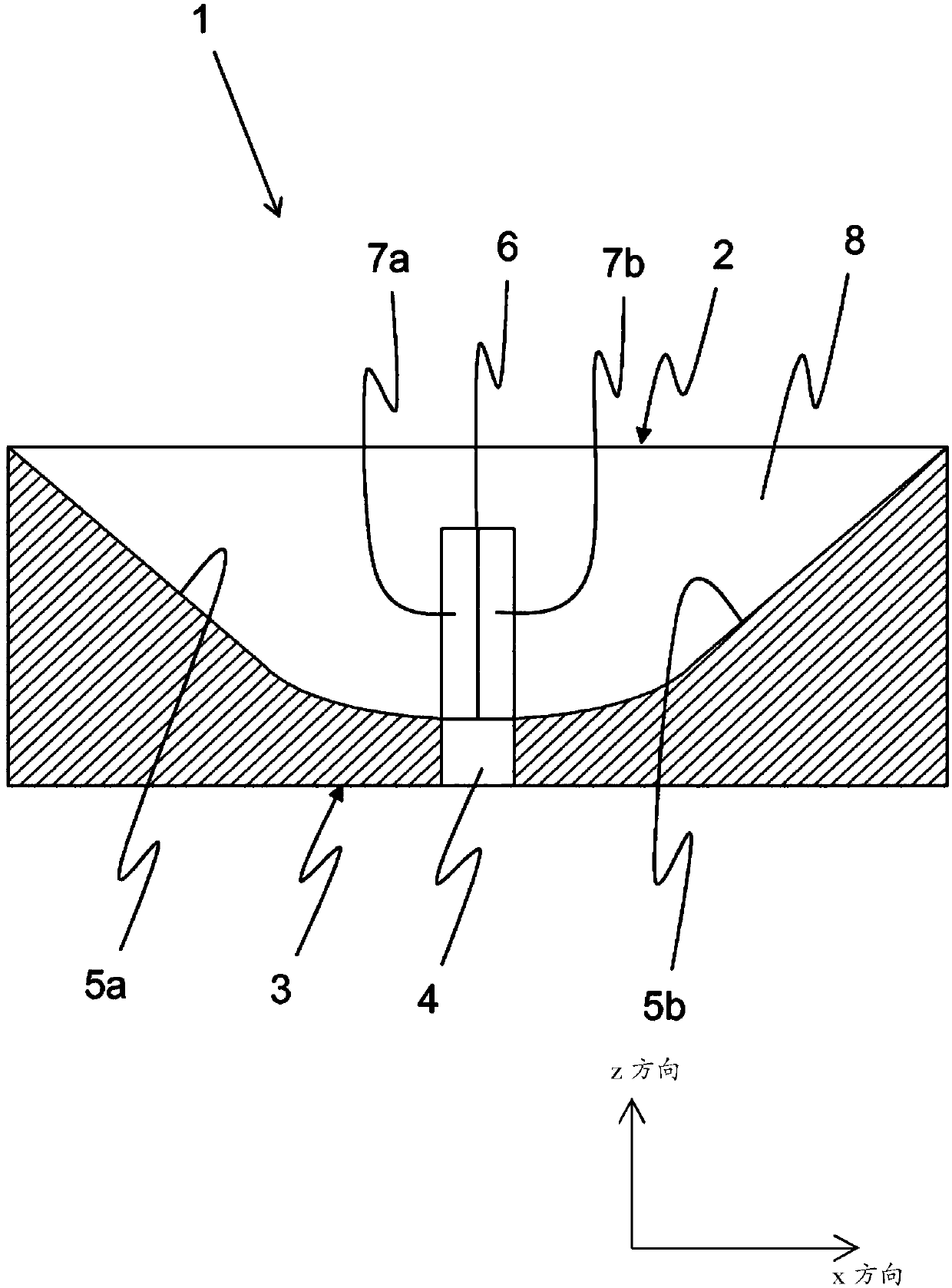

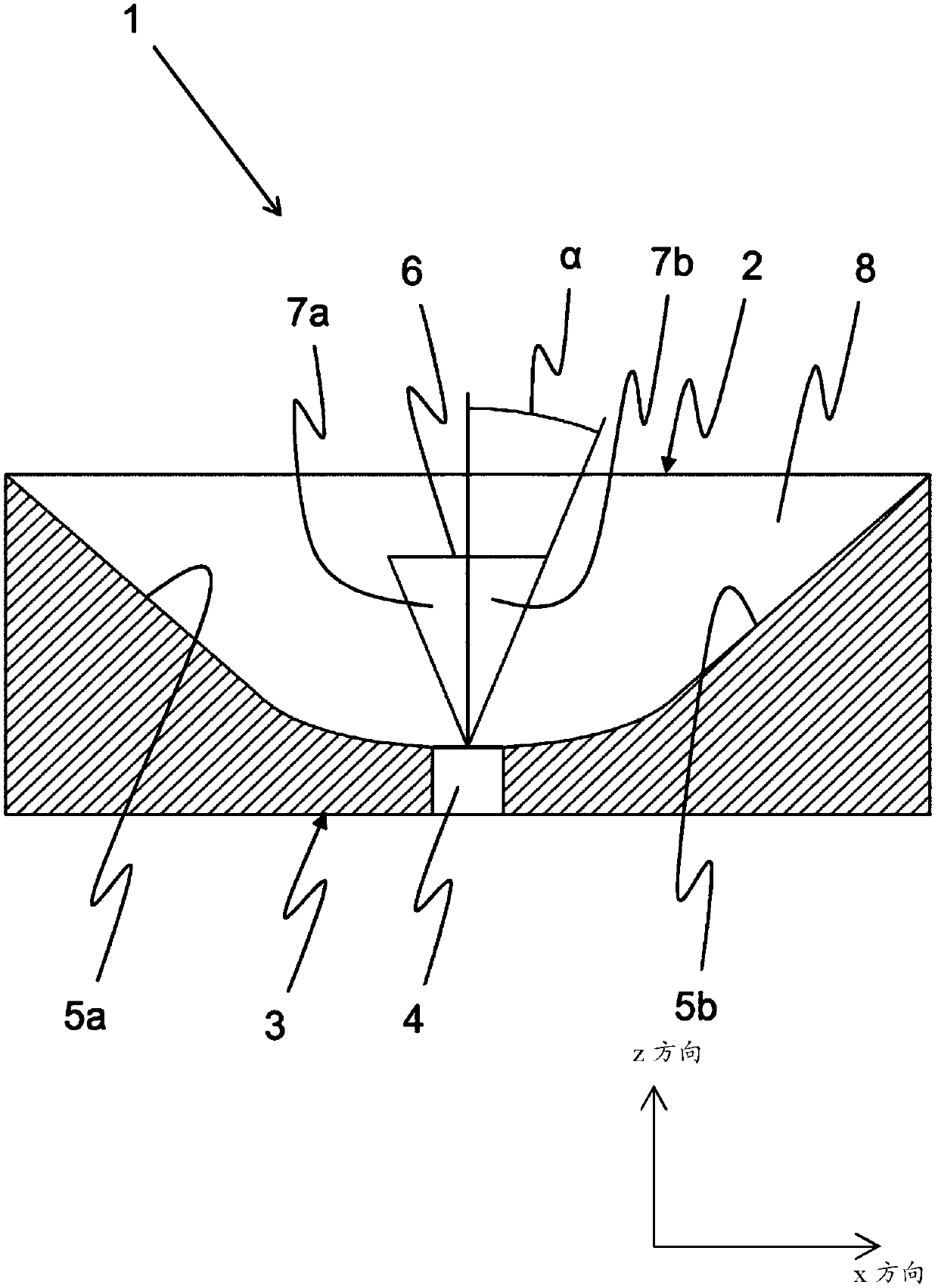

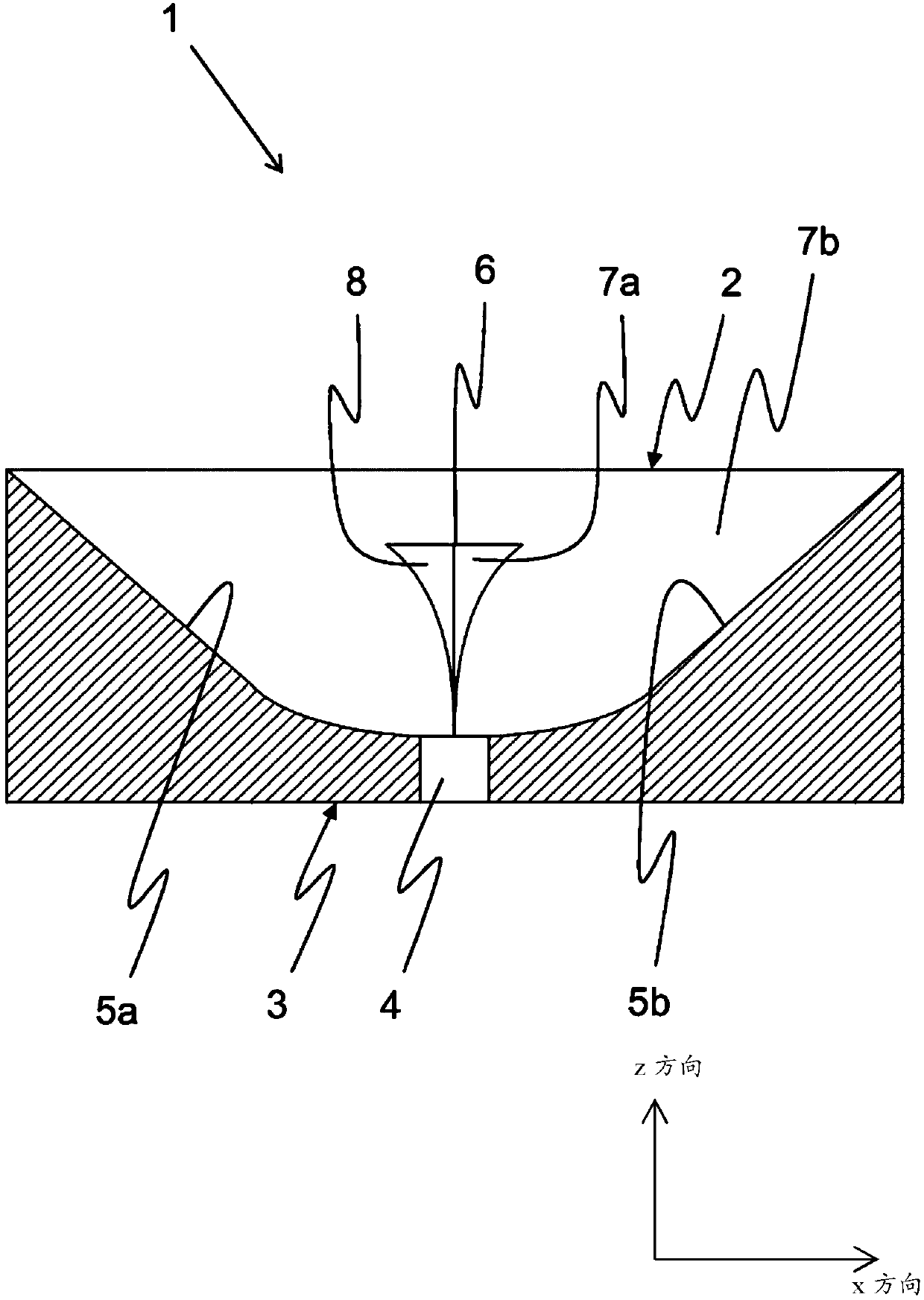

[0047] figure 1 A sectional view of a fleece funnel 1 with an inlet side 2 formed elongately in the x-direction is shown. The fibrous fleece, not shown here, enters the fleece hopper 1 via the inlet side 2 . Spaced apart from the input side 2 in the z-direction is an output side 3 . An outlet opening 4 is formed in the outlet side 3 , through which the fibrous fleece compressed into a fiber strip emerges from the fleece hopper 1 . The outlet opening 4 is preferably configured with a circular cross section. In the present exemplary embodiment, two guide surfaces 5 a , 5 b are arranged between the inlet side 2 and the outlet side 3 , which form the actual funnel function of the nonwoven funnel 1 . The fibrous fleece stretched in the x-direction enters the fleece hopper 1 via the input side 2 . At least the edge region of the fibrous nonwoven hits the guide surfaces 5 a , 5 b and is diverted from there in the direction of the output opening 4 , where it leaves the nonwoven fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com