Steak beating device

A steak and sliding device technology, applied in slaughtering, meat tenderization, food science and other directions, can solve the problems of uneven fiber, uniform surface force, low hammering efficiency, etc., and achieve uniform hammering, fast frequency, and high hammering efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

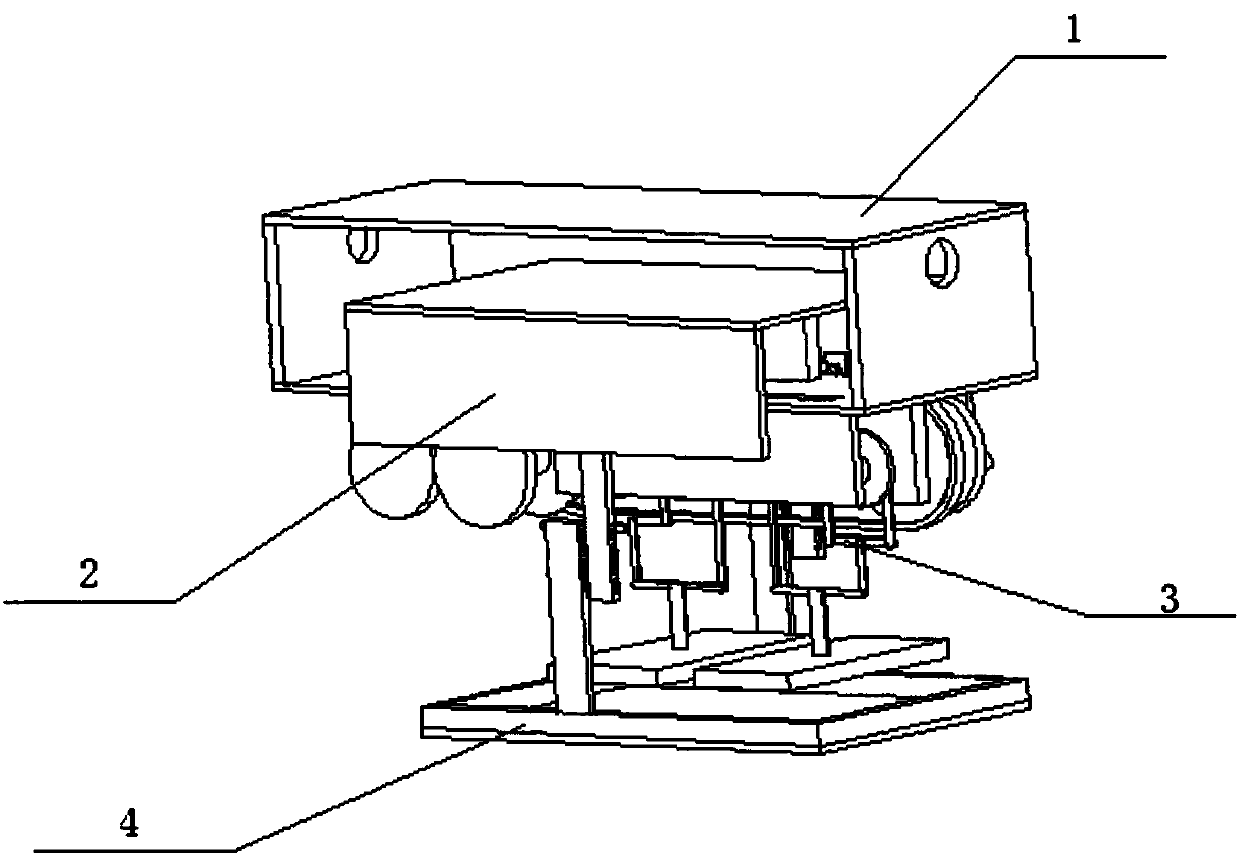

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, a steak beating device includes a main plate 1, a sliding device 2, a running mechanism 3 and a storage plate 4. The sliding device 2 is slidably connected to the main plate 1, and the running mechanism 3 is fixedly connected to the main plate 1. The sliding device 2 is connected to the storage plate 4 by bolts.

specific Embodiment approach 2

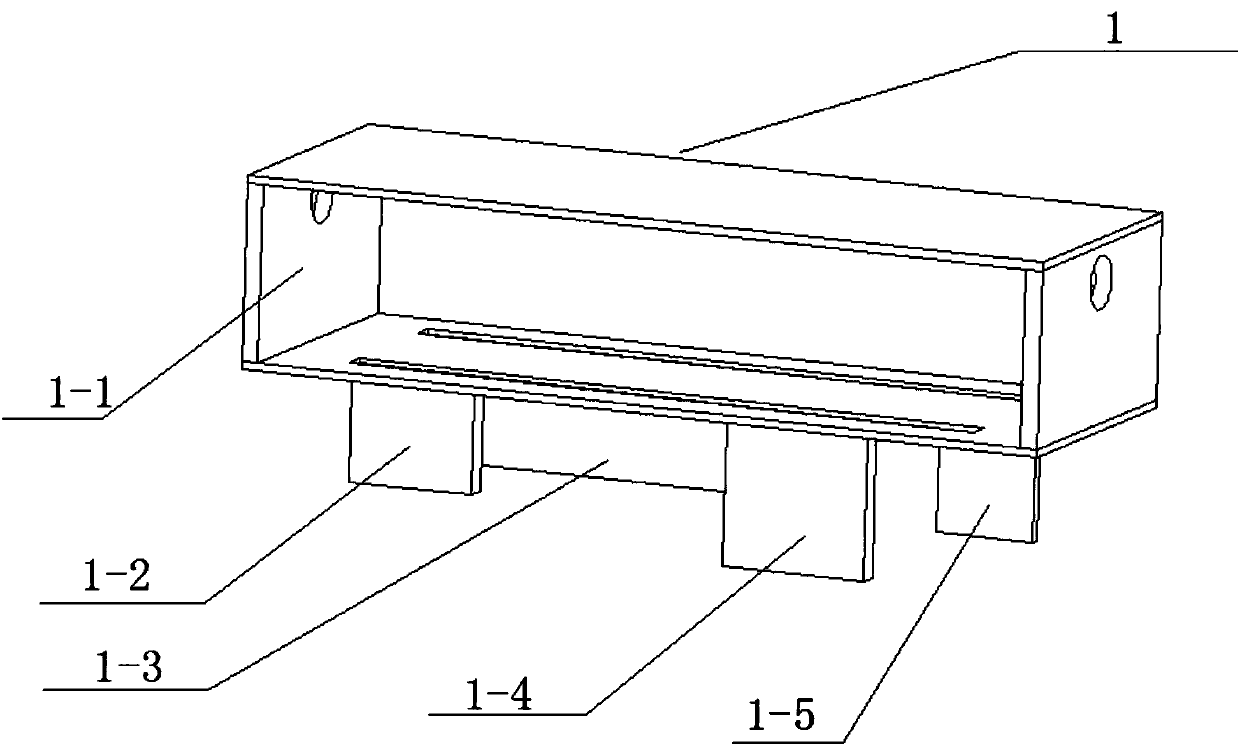

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, this embodiment will further explain Embodiment 1. The main plate 1 includes a main frame plate 1-1, a boss I1-2, a long boss 1-3, a boss II1-4 and a boss III1- 5. The upper ends of the boss I1-2, the long boss 1-3, the boss II1-4 and the boss III1-5 are all fixedly connected to the lower end of the main frame plate 1-1, and the lower end of the inner wall of the main frame plate 1-1 Two chutes are arranged on the top, and the left end and the right end of the main frame plate 1-1 are provided with through round holes, and the round holes are used for daily hanging of the device.

specific Embodiment approach 3

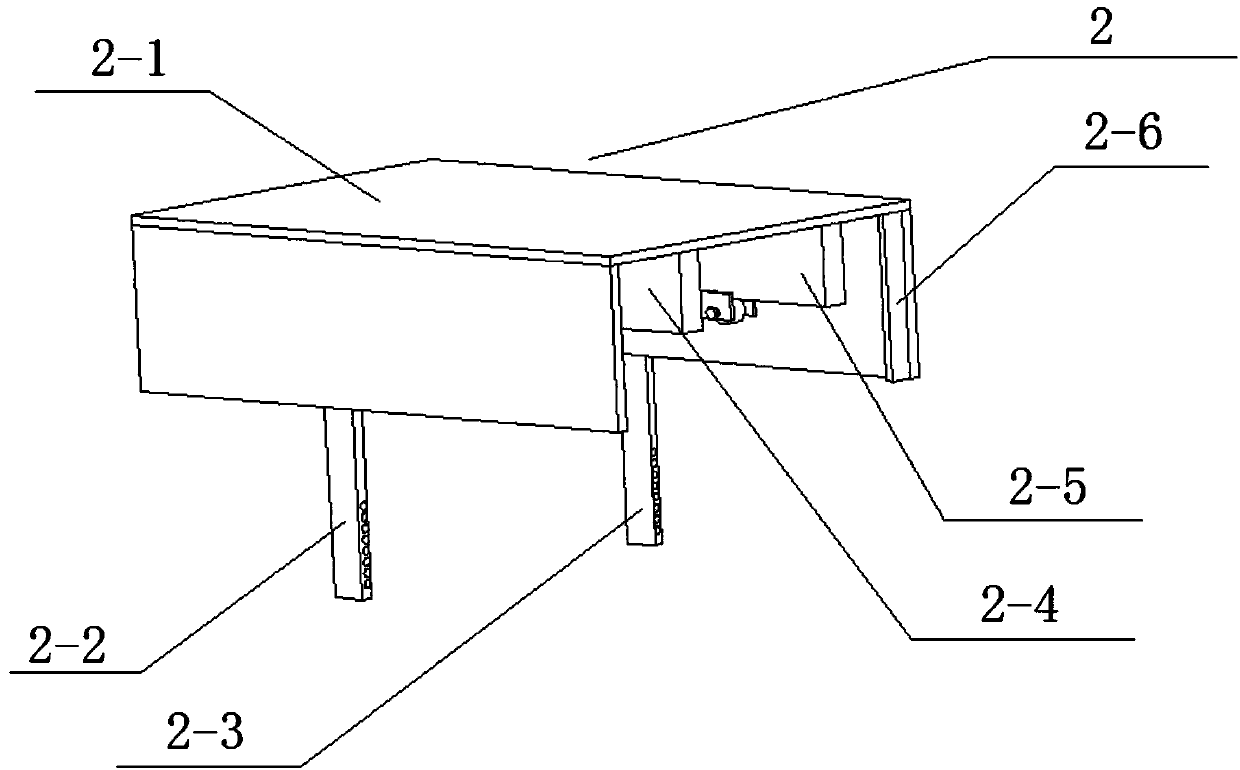

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, this embodiment will further explain Embodiment 1. The sliding device 2 includes a support plate 2-1, a connecting rod I2-2, a connecting rod II2-3, a sliding block I2-4, a sliding block II2-5, The right baffle 2-6 and the left baffle 2-7, the connecting rod I 2-2 and the connecting rod II 2-3 are provided with a plurality of left and right through, threaded holes of the same specification, the lower end of the front end of the support plate 2-1 The upper end of the connecting rod II2-3 is fixedly connected, the lower end of the rear end of the supporting plate 2-1 is fixedly connected to the upper end of the connecting rod I2-2, and the upper end of the sliding block I2-4 is fixedly connected to the upper end of the inner wall of the lower end of the supporting plate 2-1, sliding The upper end of block II 2-5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com