Injector needle cap preventing liquid leakage during air exhausting

A syringe and anti-leakage technology, applied in the field of medical devices, can solve unreasonable problems, achieve strong biological adaptability, avoid rubber crumb residue, and have a safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

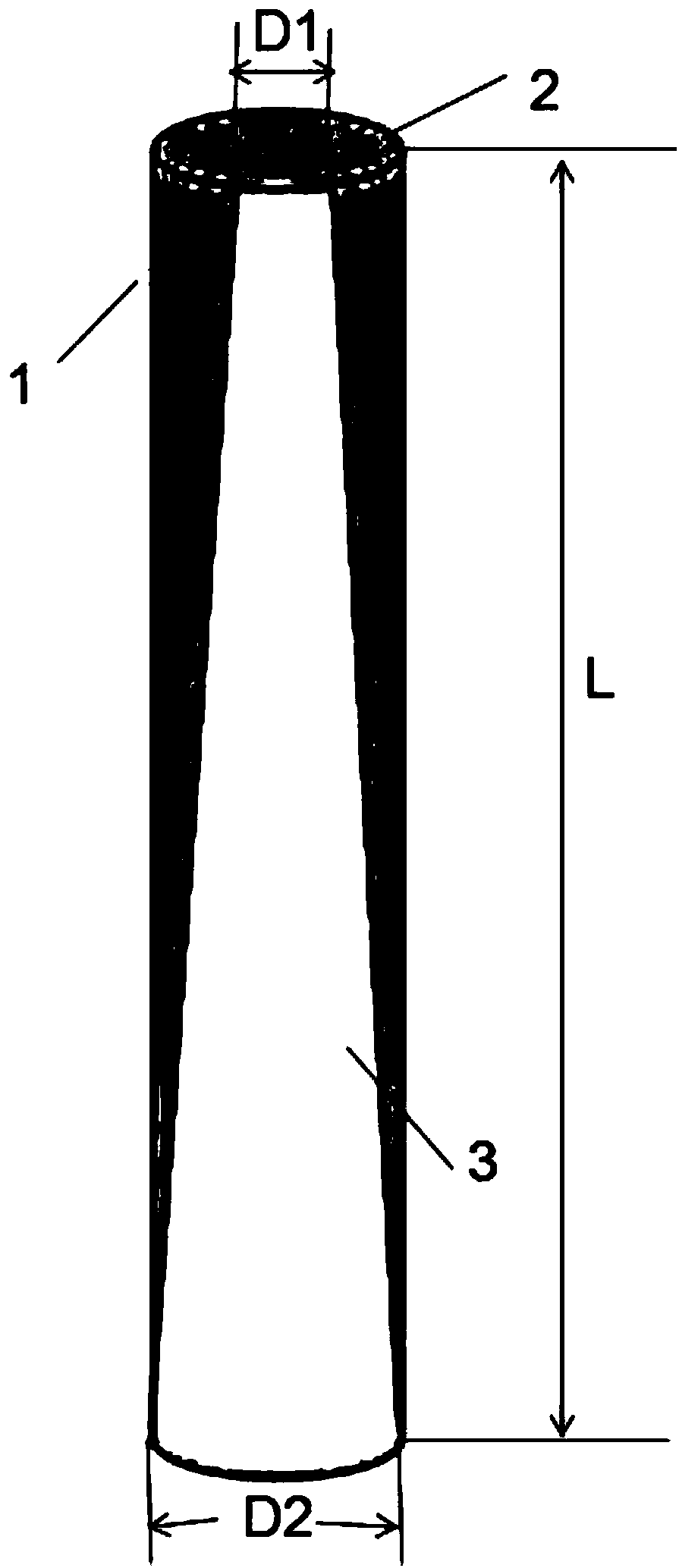

[0026] Such as figure 1 As shown, a syringe needle cap with venting and leakage prevention includes a cylindrical polyethylene needle cap tube 1 and a gas-liquid separation membrane 2 at the bottom of the needle cap tube 1; the inside of the needle cap tube 1 is designed as a trapezoidal cylinder A long and narrow hollow structure 3, the upper bottom surface of the trapezoidal cylindrical hollow structure 3 forms a closed environment with the gas-liquid separation membrane 2, and its diameter D1 is 1mm; the diameter D2 of the bottom bottom surface is the same as the diameter 1 of the bottom surface of the needle tube, D2 is 7mm; trapezoidal cylinder The length of the longitudinal axis distance L of the hollow structure 3 is 2-4cm, which is slightly less than the length of the needle cap tube; the gas-liquid separation membrane 2 is a polytetrafluoroethylene (PTFE) membrane with a pore size of 0.36-0.40nm, and the needle cap The bottom of the tube 1 forms a closed structure; the ...

Embodiment 2

[0029] Example 2 Intravenous bolus injection

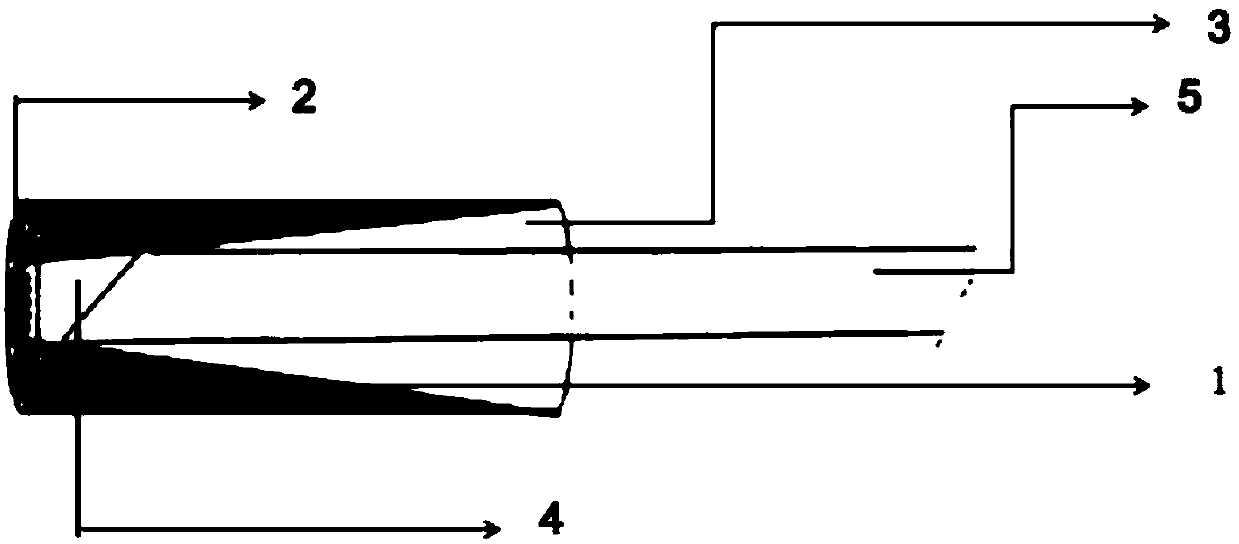

[0030] Such as figure 1 , 2 As shown, the technical solution for realizing the present invention is: a syringe needle cap for venting and preventing leakage, including a cylindrical polyethylene needle cap tube 1 with a conical hollow structure 2 and a gas-liquid separation membrane at the narrow end of the needle cap — —GORE-TEX film 3.

[0031] When using the syringe needle up, flick the needle tube to make the gas in the needle tube float to the uppermost edge, put the needle cap tube 1 on the needle 5, when the needle 5 feels resistant, fix the needle and the needle cap with one hand, and start pushing the core rod with the other hand The gas is discharged. At this time, the gas and a very small part of the liquid medicine enter the cavity 4 formed by the needle and the needle cap. The gas is discharged through the GORE-TEX membrane 3, and the liquid medicine is stored in the cavity 4, when you feel the push forward When the press...

Embodiment 3

[0032] Example 3 Intravenous drip

[0033] Such as figure 1 , 2 As shown, the technical solution for realizing the present invention is: a syringe needle cap for venting and preventing leakage, including a cylindrical polyethylene needle cap tube 1 with a conical hollow structure 2 and a gas-liquid separation membrane at the narrow end of the needle cap — —GORE-TEX film 3.

[0034] When in use, after connecting the infusion tube to pass fluid, raise one end of the infusion needle, the needle is down, and put the needle cap 1 on the infusion needle 5, when the infusion needle 5 feels resistant, fix the needle and the needle cap with one hand and start with the other hand Adjust the flow rate regulator of the squeezed infusion tube to discharge the gas. At this time, the gas and a very small part of the liquid enter the cavity 4 formed by the needle and the needle cap. The gas is discharged through the GORE-TEX membrane 3, and the liquid is stored in the cavity. In 4, when the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com