Positioning device for welded part matching

A technology for positioning devices and welding parts, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as affecting welding accuracy and welding quality, difficult to meet market demands, and prone to offset or displacement. Achieve the effect of good practicability, fast fixation and good use stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

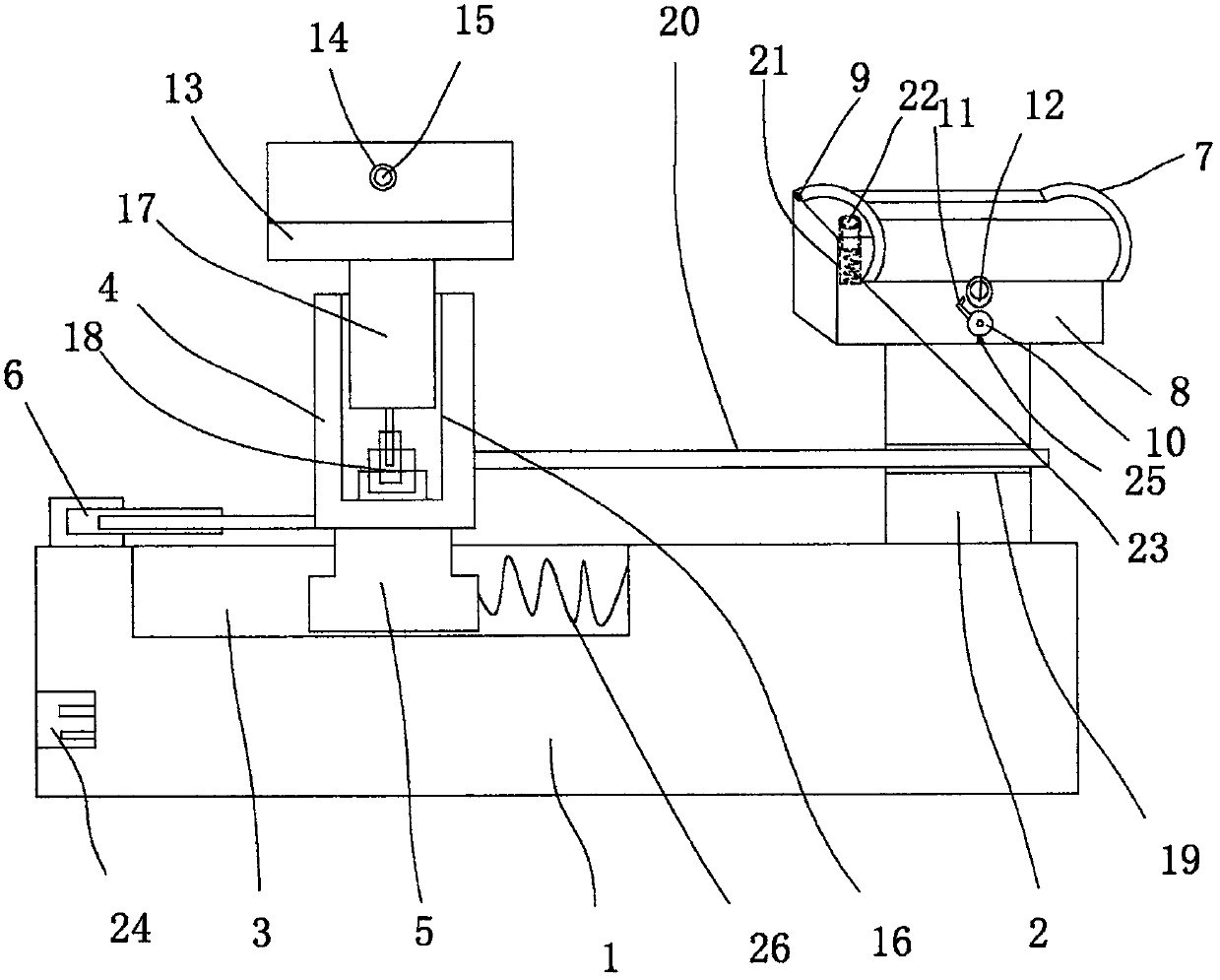

[0016] figure 1 A specific embodiment of the present invention is shown, wherein figure 1 It is a schematic diagram of the structure of the present invention.

[0017] see figure 1 , A positioning device for matching welding parts, comprising a base 1, a fixed bracket 2 arranged on the base 1, a movable chute 3 with an opening on the top surface is provided on the base 1, and a movable bracket 4, The bottom of the movable bracket 4 is provided with a movable sliding block 5 that cooperates with the movable sliding groove 3, a control cylinder 6 is fixed on the base 1, and the piston shaft of the control cylinder is fixed on the movable sliding block, The movable bracket 4 moves to the fixed bracket under the action of the control cylinder. A clamping base 8 and a clamping buckle block 7 are fixed on the top of the fixed bracket 2. One end of the clamping buckle block 7 rotates The shaft 9 is connected to the clamping base 8 and a locking disc 10 is fixed at the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com