Complete process production line for pot cover

A whole process, pot lid technology, applied in the directions of cooking utensil lids, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as poor production efficiency and difficult quality assurance, and achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

[0027] The definition of relevant direction of the present invention is to be defined according to the direction that tempered glass pot cover is transported.

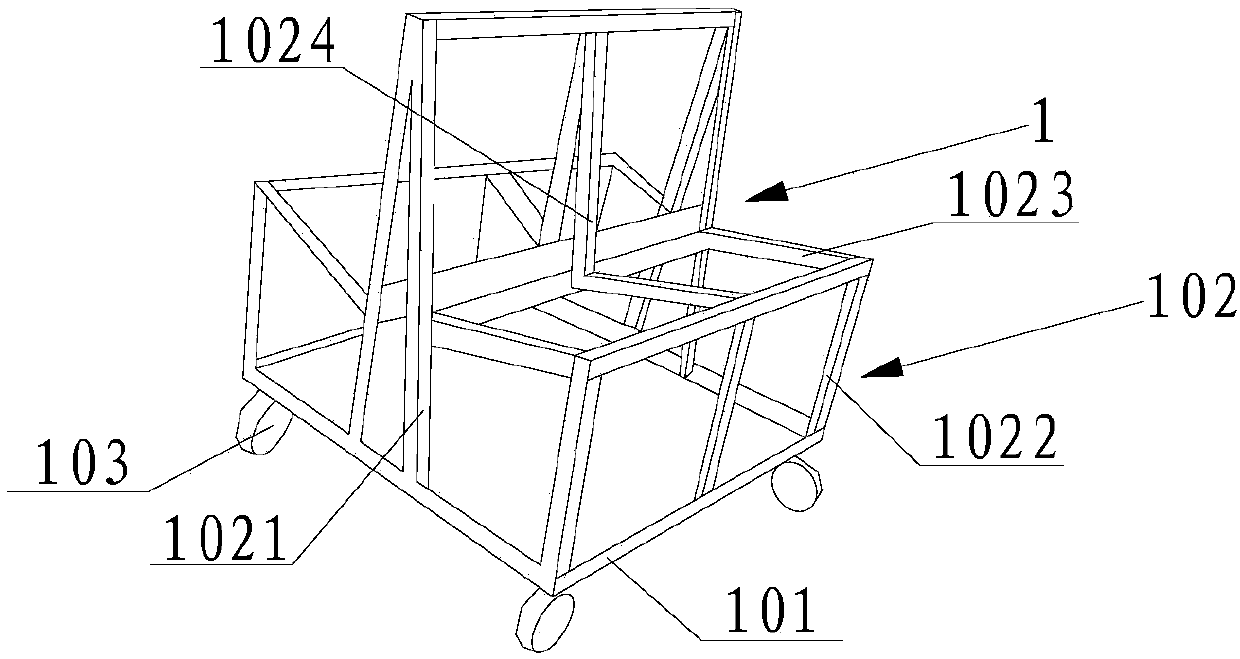

[0028] Such as figure 1 The raw material rack body 1 shown is used for placing tempered glass pieces; it mainly includes a first bottom frame 101 , a shelf 102 and a first roller 103 . Wherein, the first bottom frame 101 is arranged horizontally, and a plurality of first rollers 103 are installed on its bottom. There are two groups of storage racks 102, which are installed on the upper surface of the first bottom frame 101 and arranged symmetrically. On the upper surface of the bottom frame 101 and the second support frame 1021 spaced apart from the first support frame 1022, one side (i.e. a long side of the third support frame 1023) is installed on the top of the first support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com