Six-degree-of-freedom parallel mechanism for motion compensation

A technology of motion compensation and degree of freedom, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc. It can solve the problems of unfavorable motion compensation device application and less compensation degrees of freedom, and achieve the effects of low cost, simple control, and simple geometric structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

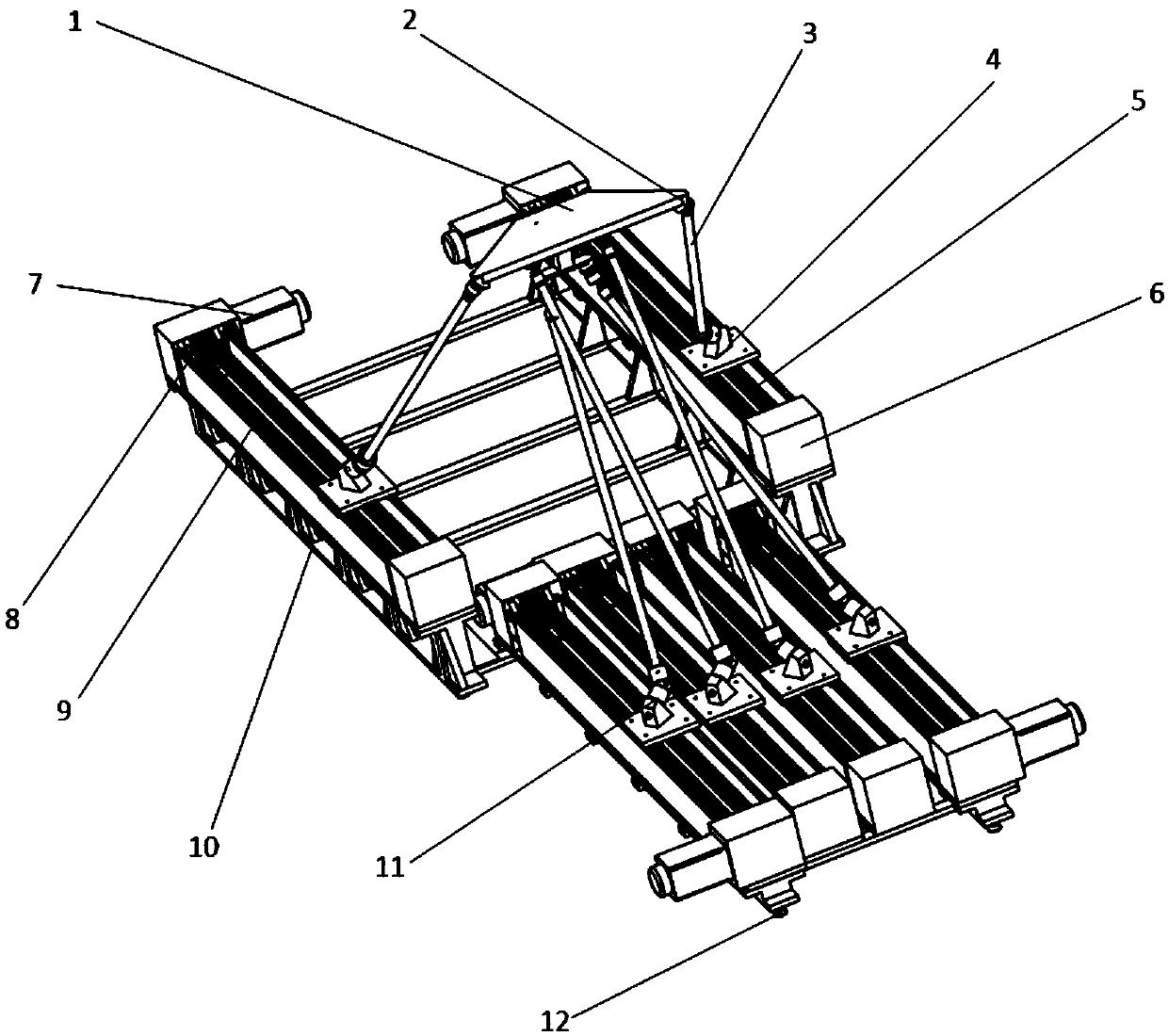

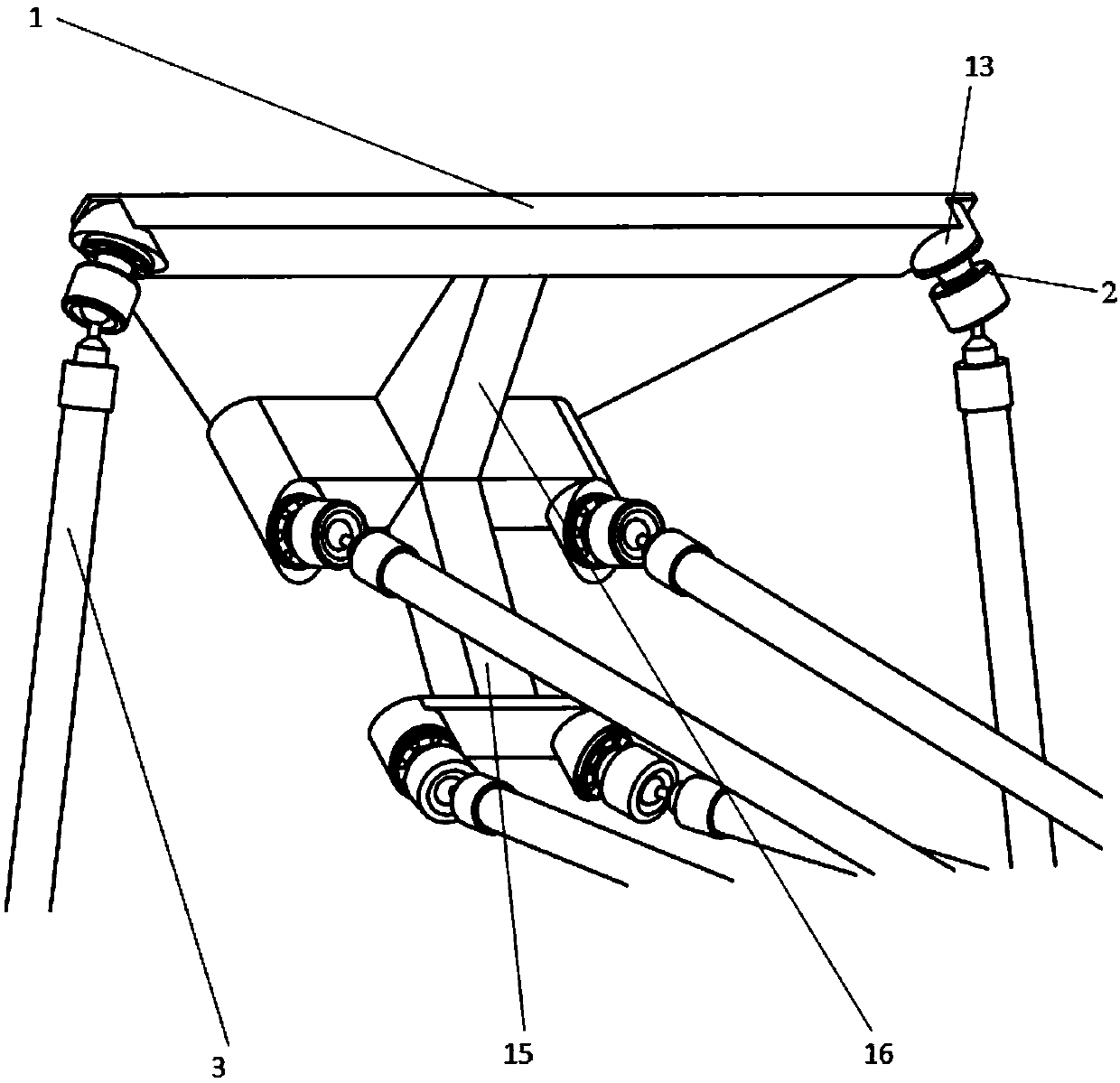

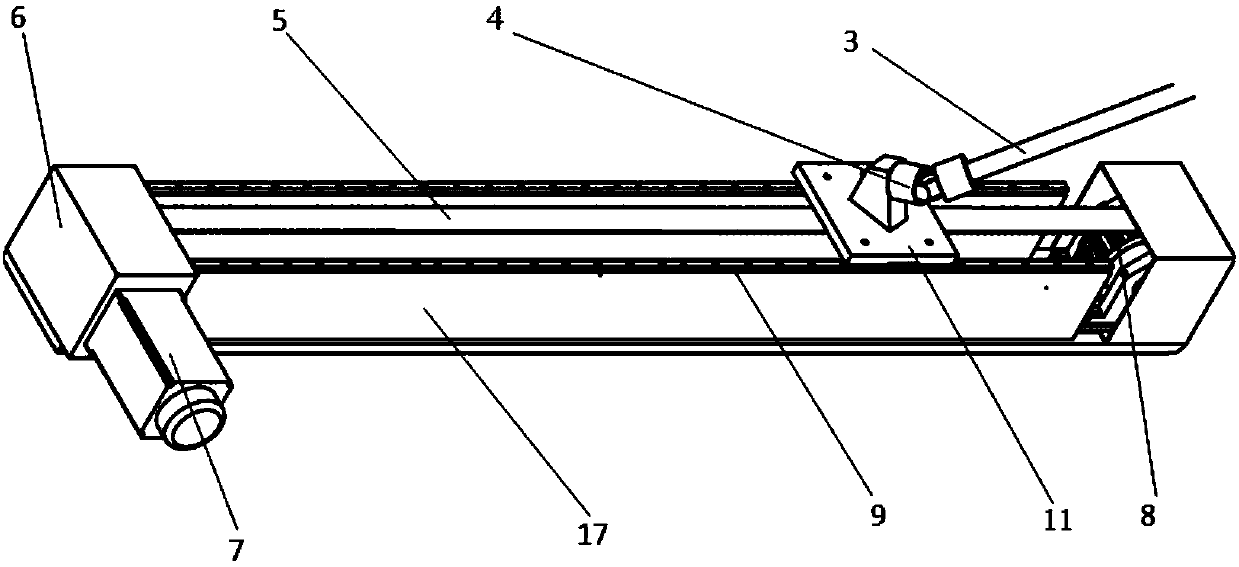

[0027] Such as Figure 1-4 As shown, a six-degree-of-freedom parallel mechanism for motion compensation includes a frame 10, a drive actuator assembly, and a motion compensation device. The frame 10 includes a fence-like frame that is arranged vertically and horizontally by several steel pipes 19 and welded as a whole. I and the frame II fixedly installed on the front end of the frame I, the bottom of the frame I and the frame II are all equipped with some foot pads 12, which also facilitates the handling of the device while ensuring the stability of the whole parallel mechanism and transport. All the longitudinal steel pipes 19 on the left and right sides of the frame 1 are fixedly equipped with a frame support plate 18, and the base of each of the frame support plates 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com