Steel coil rack

A steel coil rack and steel structure technology, applied in the field of steel coil racks, can solve problems such as unusable, falling off of the container bottom plate, and large force on the contact part of the container bottom plate, and achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now do further detailed explanation in conjunction with accompanying drawing.

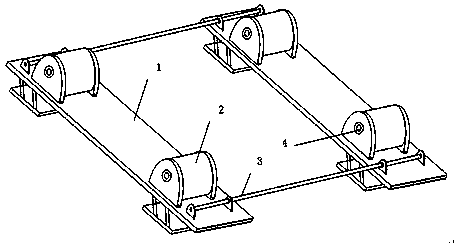

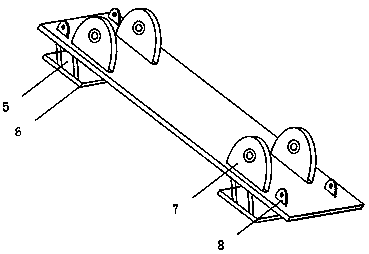

[0014] Such as figure 1 or figure 2 As shown, the steel coil rack includes two bases 1, rubber wheels 2, connecting rods 3, pin shafts 4 and nuts; each base 1 is provided with two pairs of large lugs 7, two pairs of small lugs 8 and two bases The bottom plate 6; the rubber wheel 2 is fixedly installed in the middle of the pair of large ear plates through the pin shaft 4; the connecting rod 3 passes through the small ear plate 8 to connect the two bases 1, and the distance between the two bases 1 can be changed by adjusting the length of the connecting rod 3 The distance can meet the needs of different steel coil sizes. The bottom plate of the base 6 increases the contact area with the bottom plate of the container, which can effectively prevent the bottom plate of the container from falling off.

[0015] The rubber wheel 2 is composed of an external cladding material and an internal stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com