A kind of slow rebound sponge and preparation method thereof

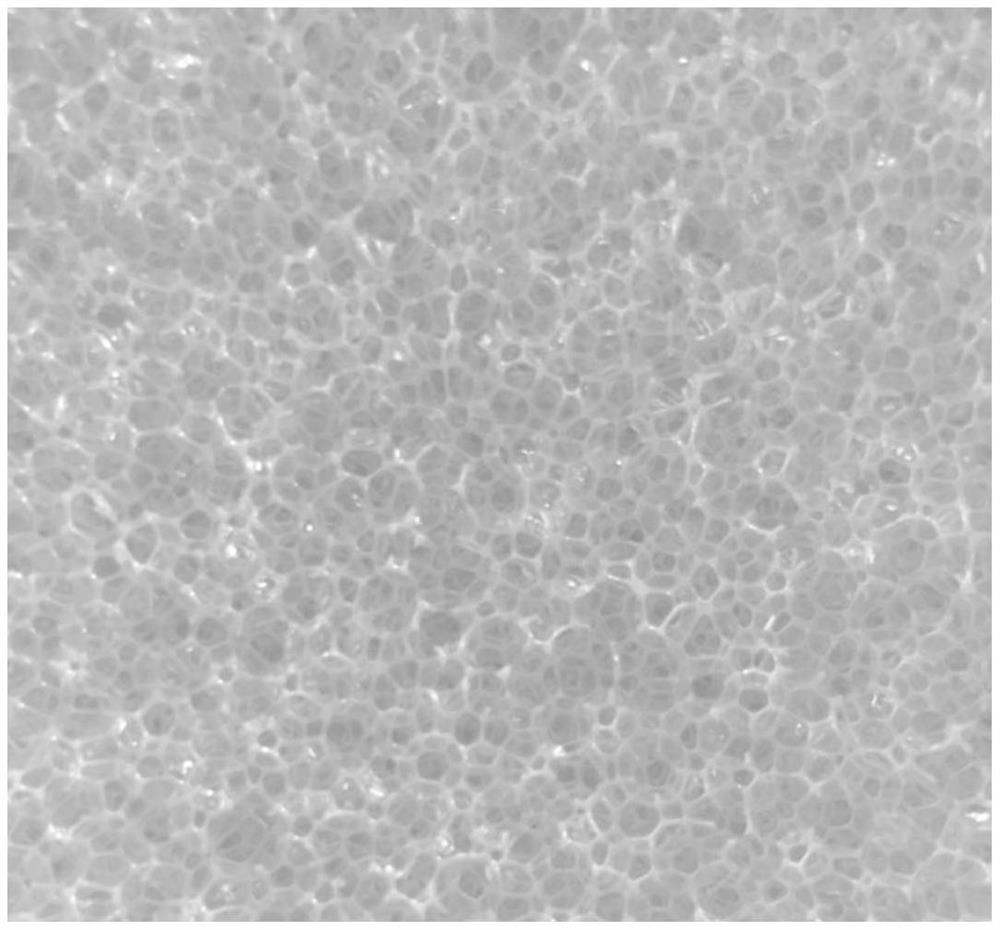

A slow-rebound sponge and slow-rebound polyether technology, applied in the field of sponge products, can solve the problems of difficult drying, poor air permeability, cells cannot quickly restore shape, etc., and achieve the effect of eliminating fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

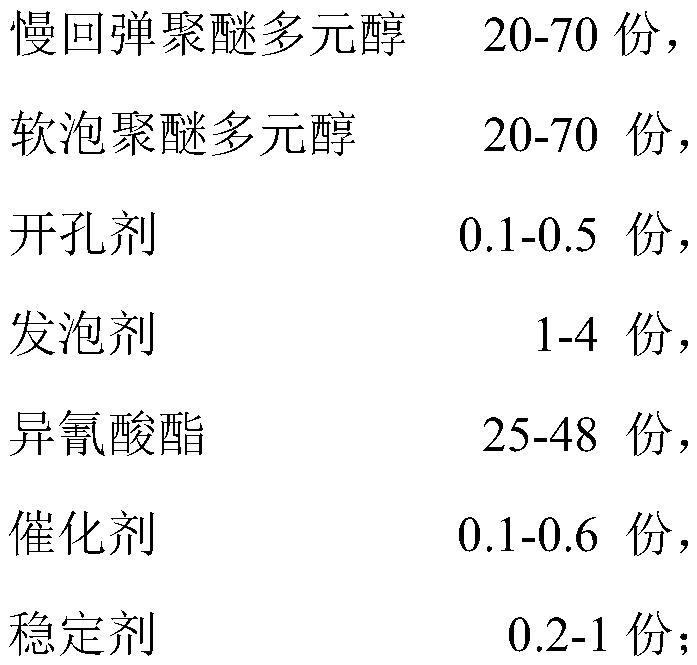

[0040] A slow rebound sponge, comprising the following raw materials by weight:

[0041]

[0042] The preparation method of above-mentioned slow resilience sponge, comprises the following steps:

[0043] (1) Mix Y-1030 and MN-3050D, stir at 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 1;

[0044] (2) After mixing water, A-33 and B8123 according to the ratio, add it to mixture 1 at a speed of 100 rpm, stir for 1 minute, and control the temperature at 17°C to obtain mixture 2;

[0045] (3) After mixing Y-1900 and T9 according to the ratio, add it to mixture 2, stir at a speed of 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 3;

[0046] (4) Add TDI-80 to mixture 3, stir at 150 rpm for 2 seconds, and control the temperature at 17°C to obtain mixture 4;

[0047] (5) Pour the mixture 4 into the mold box, react quickly within 1-10 seconds, and then complete the foaming within 0.5-3 minutes, and react into a large mesh ...

Embodiment 2

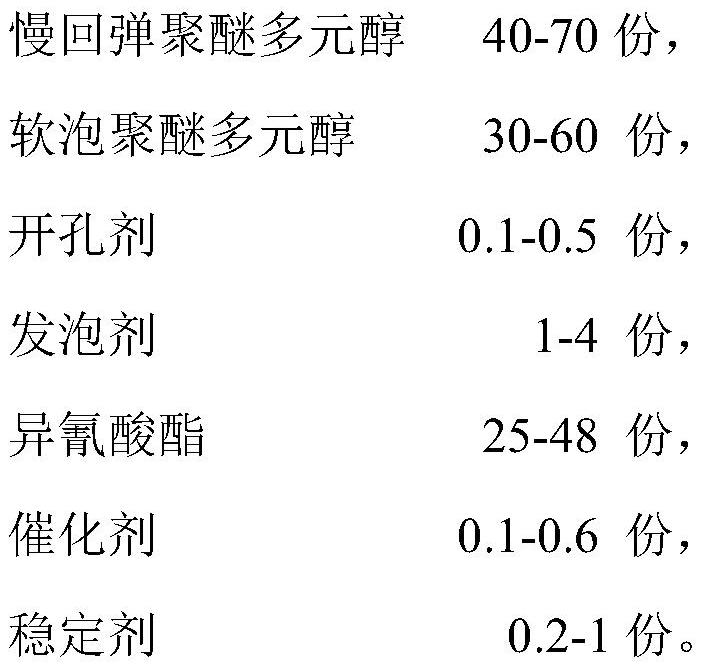

[0050] A slow rebound sponge, comprising the following raw materials by weight:

[0051]

[0052]

[0053] The preparation method of above-mentioned slow resilience sponge, comprises the following steps:

[0054] (1) Mix Y-1030 and MN-3050D, stir at 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 1;

[0055](2) After mixing water, A-33 and B8123 according to the ratio, add it to mixture 1, stir at a speed of 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 2;

[0056] (3) After mixing Y-1900 and T9 according to the ratio, add it to mixture 1, stir at a speed of 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 3;

[0057] (4) Add TDI-80 to mixture 3, stir at 150 rpm for 2 seconds, and control the temperature at 17°C to obtain mixture 4;

[0058] (5) Pour the mixture 4 into the mold box, react quickly within 1-10 seconds, and then complete the foaming within 0.5-3 minutes, and react into a ...

Embodiment 3

[0061] A slow rebound sponge, comprising the following raw materials by weight:

[0062]

[0063]

[0064] The raw materials are weighed according to the proportion, and the preparation is carried out through the following steps:

[0065] (1) Mix Y-1030 and MN-3050D, stir at 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 1;

[0066] (2) After mixing water, A-33 and B8123 according to the ratio, add it to mixture 1, stir at a speed of 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 2;

[0067] (3) After mixing Y-1900 and T9 according to the ratio, add it to mixture 2, stir at a speed of 100 rpm for 1 minute, and control the temperature at 17°C to obtain mixture 3;

[0068] (4) Add TDI-80 to mixture 3, stir at 150 rpm for 2 seconds, and control the temperature at 17°C to obtain mixture 4;

[0069] (5) Pour the mixture 4 into the mold box, the mixture reacts rapidly within 1-10 seconds, and then completes the foamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com