A kind of high entropy alloy material and preparation method thereof

A high-entropy alloy and alloy powder technology, which is applied in the coating process and coating of metal materials, can solve the problem of limited amount of added elements, and achieve the effects of no cracks, good high-temperature stability, and high-temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

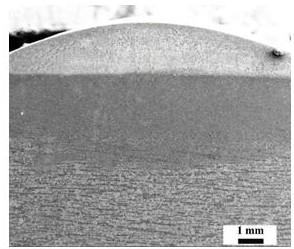

Image

Examples

Embodiment 1

[0026] The laser cladding high-entropy alloy material in this embodiment is composed of six metal element powders of Ti, Al, Cu, Ni, Mn, Co, Nb and Hf, and the atomic percentage of each component is 17% Cu, 16% Ni, 15% Mn, 16% Co, 17% Nb, 19% Hf.

[0027] The preparation method of the high-entropy alloy material cladding layer described in this embodiment comprises the following steps:

[0028] (1) Grind the substrate with 600-grit sandpaper to remove the scale, and then clean it with alcohol;

[0029] (2) Vacuum ball mill each weighed powder for 2.5 hours and fully mix to obtain alloy powder with a particle size of 180-250 mesh;

[0030] (3) Evenly press the alloy powder material obtained in step (2) on the surface of the base material treated in step (1) to form a prefabricated layer. The thickness of the prefabricated powder is 1.0mm. After drying, the cladding layer can be obtained by laser cladding , The process parameters for laser cladding are: laser power 3500W, scan...

Embodiment 2

[0035] The laser cladding high-entropy alloy material in this embodiment is composed of six metal element powders of Ti, Al, Cu, Ni, Mn, Co, Nb and Hf, and the atomic percentage of each component is 18% Cu, 15% Ni, 16% Mn, 17% Co, 19% Nb, 15% Hf.

[0036] The preparation method of the high-entropy alloy material cladding layer described in this embodiment comprises the following steps:

[0037] (1) Grind the substrate with 600-grit sandpaper to remove the scale, and then clean it with alcohol;

[0038] (2) Vacuum ball mill each weighed powder for 3 hours and fully mix to obtain alloy powder with a particle size of 200-300 mesh;

[0039] (3) Evenly press the alloy powder material obtained in step (2) on the surface of the base material treated in step (1) to form a prefabricated layer. The thickness of the prefabricated powder is 0.9mm. After drying, the cladding layer can be obtained by laser cladding , The process parameters for laser cladding are: laser power 4000W, scanni...

Embodiment 3

[0044] The laser cladding high-entropy alloy material in this embodiment is composed of six metal element powders of Ti, Al, Cu, Ni, Mn, Co, Nb and Hf, and the atomic percentage of each component is 20% Cu, 18% Ni, 13% Mn, 15% Co, 13% Nb, 21% Hf.

[0045] The preparation method of the high-entropy alloy material cladding layer described in this embodiment comprises the following steps:

[0046] (1) Grind the substrate with 600-grit sandpaper to remove the scale, and then clean it with alcohol;

[0047] (2) Carry out vacuum ball milling for each weighed powder, the ball milling time is 3.5 hours, and fully mix to obtain alloy powder with a particle size of 180-280 mesh;

[0048](3) Evenly press the alloy powder material obtained in step (2) on the surface of the base material treated in step (1) to form a prefabricated layer. The thickness of the prefabricated powder is 1.1mm. After drying, the cladding layer can be obtained by laser cladding , The process parameters for lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com