Yarn-dyed leisure fabric and weaving technology for same

A fabric and yarn-dyed technology, which is applied in the field of yarn-dyed casual fabrics and its weaving technology, can solve the problems of not soft texture, insufficient warmth retention, insufficient elasticity, etc., and achieve the effect of soft texture, soft hand feeling, good elasticity and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structure, features and effects of the present invention, a preferred embodiment is given, which is described in detail in conjunction with the accompanying drawings as follows:

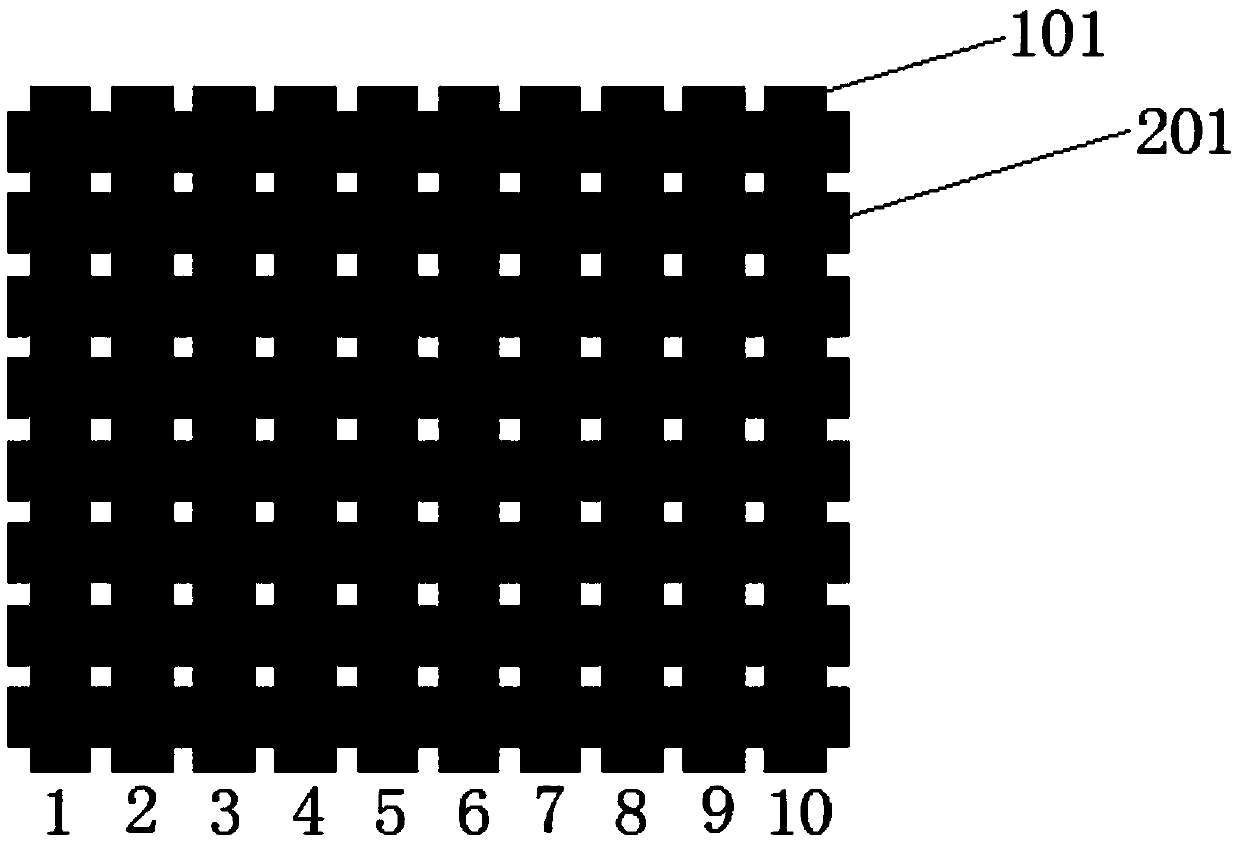

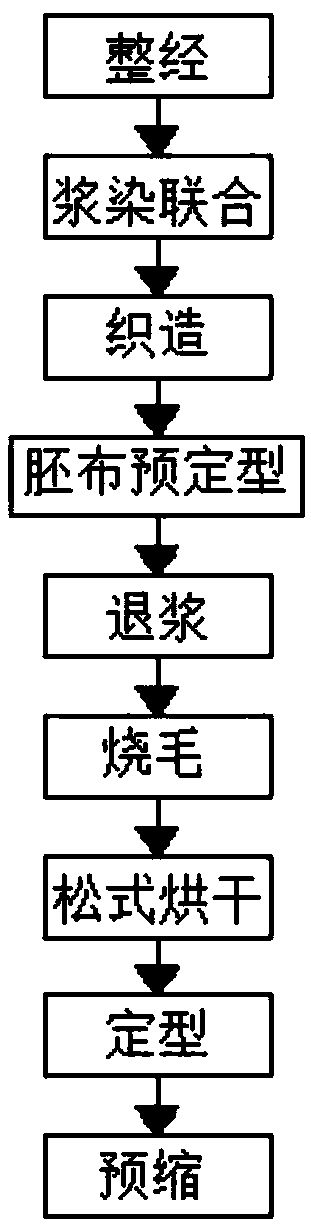

[0032] according to Figure 1 to Figure 2 As shown, a yarn-dyed leisure fabric includes warp yarns 101 and weft yarns 201. The yarn-dyed leisure fabric is interwoven by warp yarns 101 and weft yarns 201. The front side of the yarn-dyed leisure fabric is diagonal to the right. The fabric body 1, 2, 3, 4, 5, 6, 7 and 8 of the yarn-dyed leisure fabric are worn smoothly, 1 per heald, 1 reed per 4 yarns, and the selvage 9 and 10 of the yarn-dyed leisure fabric, 1 per heald, 1 reed per 5, a process for weaving yarn-dyed casual fabrics, including: warping-sizing-weaving-pre-formed fabric-desizing-singeing-loose drying-shaping-pre-preparation Shrink.

[0033] according to image 3 Said yarn-dyed leisure fabric is composed of a three-layer ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap