Construction site dust removing device

A kind of dust removal equipment and construction site technology, which is applied to mixers, mixers using liquid separation agents, and mixers with rotating stirring devices, etc. It can solve the problem of poor mixing effect of cold water and normal temperature water, inability to fold the sprinkling part, and easy cold and hot water Uneven problems, achieve compact structure, improve dust removal range and uniformity of dust removal, and reduce labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

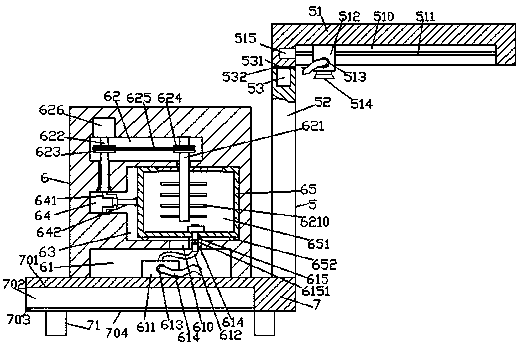

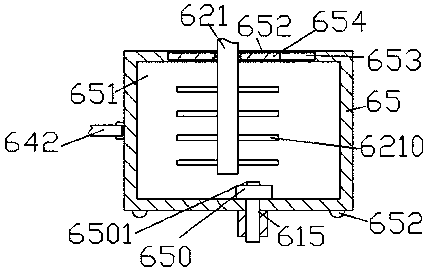

[0024] Such as Figure 1-Figure 5As shown, a construction site dust removal equipment of the present invention includes a base 7 and a dust removal box 6 fixed on the top of the base 7, and a dust removal device 5 is provided on the base 7 on the right side of the dust removal box 6, The bottom of the dust removal box 6 is provided with a first channel groove 61, and the dust removal box 6 above the first channel groove 61 is provided with an embedded groove 64 and a sliding cavity 63, and the embedded groove 64 is located in the sliding The middle position of the inner wall on the left side of the cavity 63 and the right end of the insertion groove 64 and the left end of the sliding cavity 63 pass through. The sliding cavity 63 is provided with an atomization box 65. A knuckle shaft 641 is connected by rotation and fit, and a push-pull rod 642 is flexibly connected between the knuckle shaft 641 and the left end of the atomization box 65. A storage chamber 651 is provided insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com