Method and system of testing verticality between two planes

A testing method and verticality technology, applied in the field of tooling testing, can solve the problems of unsuitability for mass testing, complex testing process and low precision, and achieve the effects of simple structure, simple and convenient operation, and high testing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

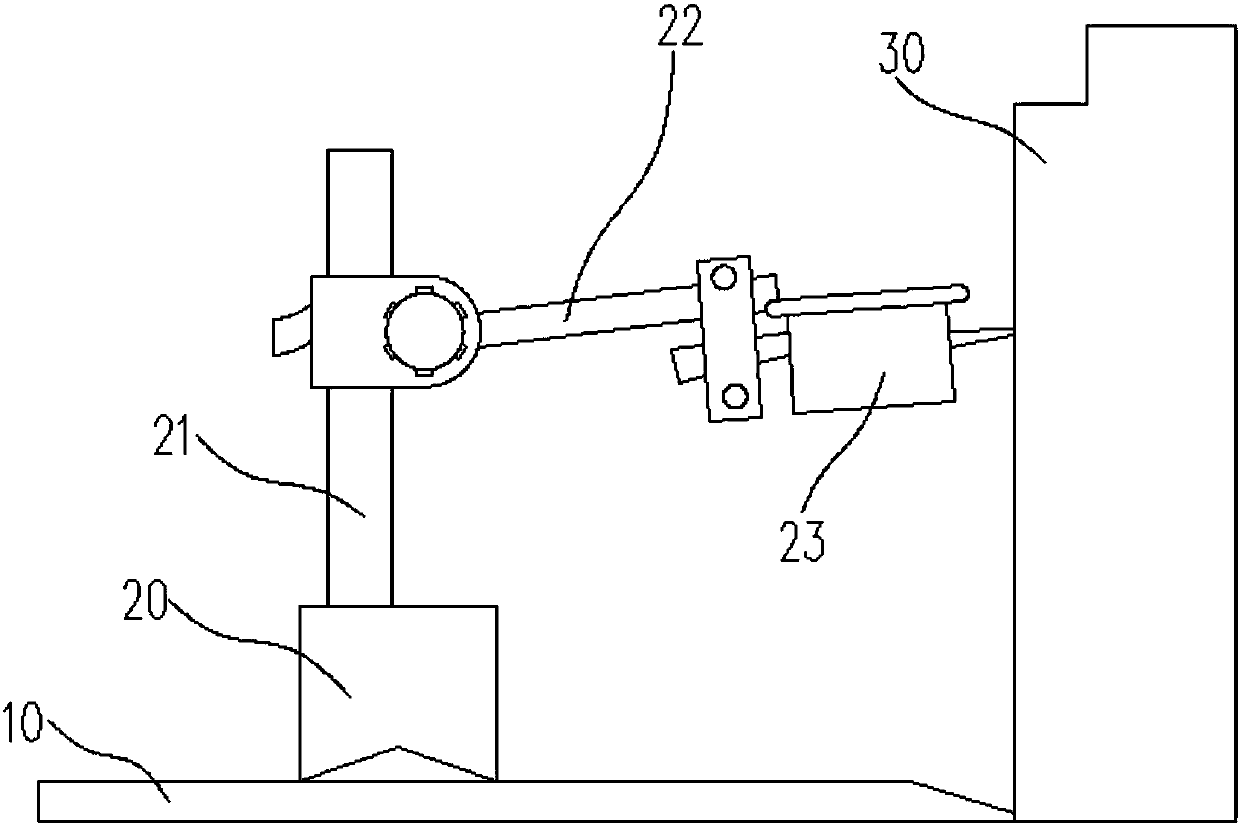

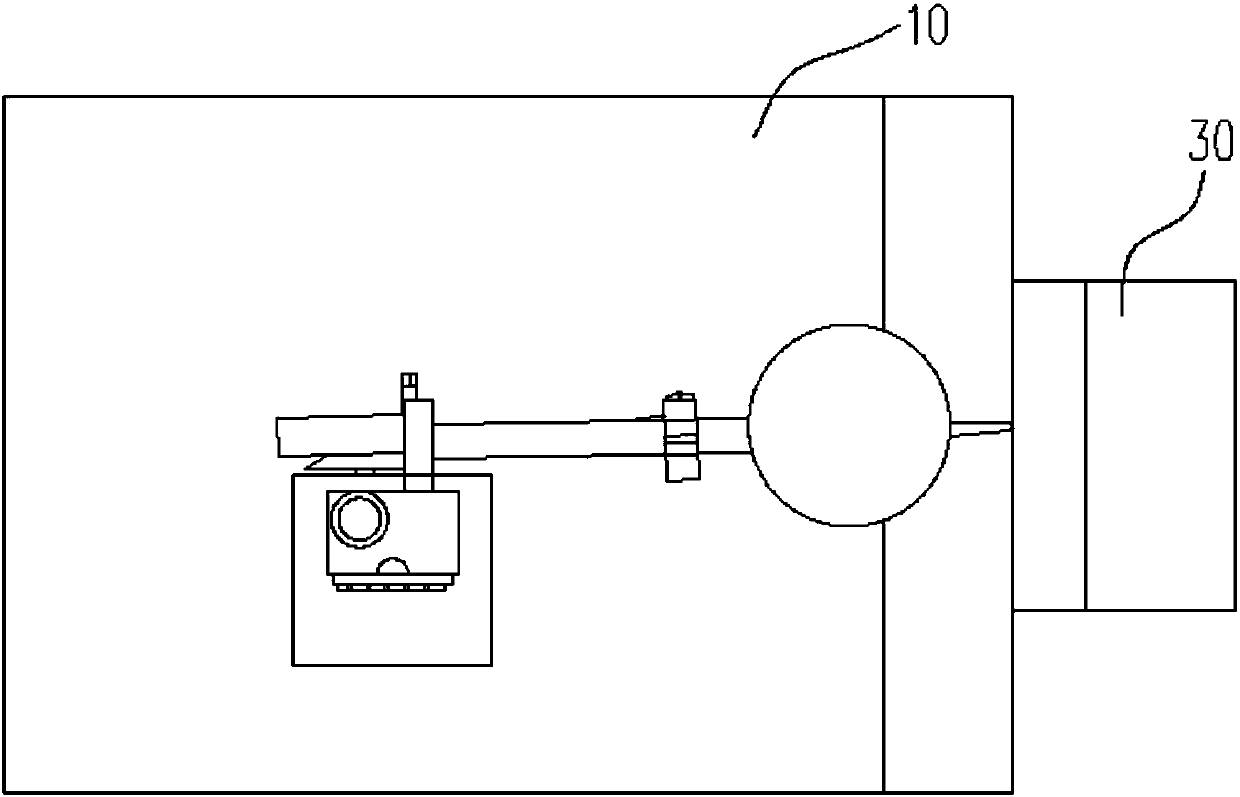

[0035] Such as Figure 1-2 Shown, a kind of testing system of perpendicularity between two planes, comprises support frame, dial indicator 23 and push plate 10; Support frame comprises table base 20, support column 21 and connecting column 22; Support column 21 is arranged on On the top surface of the seat 20, the support column 21 is provided with a sliding block, and the sliding block can move up and down along the support column 21; The sub-table 23 is connected; the table base 20 is arranged on the push plate 10 .

[0036] The test system for perpendicularity between two planes provided by the embodiment of the present invention has simple structure, low cost, high measurement accuracy, and is suitable for batch detection.

Embodiment 2

[0038] A test method for perpendicularity between two planes comprising:

[0039] Manufacturing steps of the push plate 10: take the base plate, grind the upper surface and the lower surface of the base plate to obtain the push plate 10;

[0040] Test instrument preparation steps: take the table base 20, set the support column 21 on the top surface of the table base 20, the support column 21 is horizontally provided with the connecting column 22, fix the dial indicator 23 on the connecting column 22, the dial indicator 23 The contacts protrude laterally;

[0041] Layout steps: place the push plate 10 on the test platform, and the lower surface of the push plate 10 is attached to the test platform; place the meter base 20 on the push plate 10, and the contact of the dial gauge 23 is flush with the front end of the push plate 10 Qi, or, the contact of dial gauge 23 stretches out the front end of push plate 10 forward;

[0042] Calibration steps: Take the standard part, the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com