Substrate manufacturing method

A manufacturing method and substrate technology, which are applied in the manufacturing field of substrates, can solve the problems of high metal reflectivity, metal electrodes visually recognized by a touch panel, reflection of external light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0237]

[0238] The first positive type composition can be prepared by blending the above-mentioned components in predetermined ratios, followed by mixing and stirring by a usual method. In addition, if necessary, further filtration may be performed using a mesh, a membrane filter, or the like.

[0239] [Second Positive Type Composition]

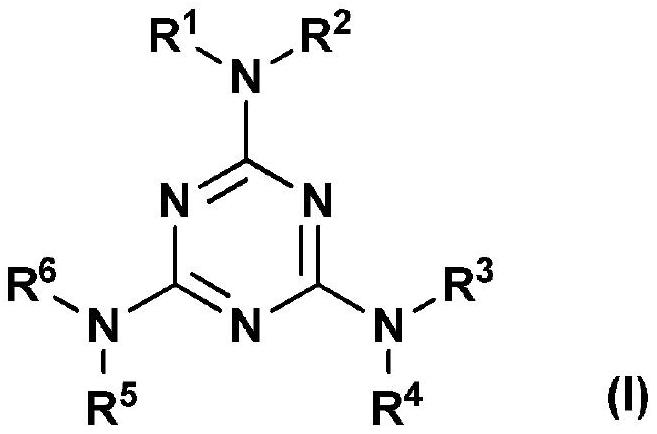

[0240] As described above, the second positive composition includes a resin (A2) that increases solubility in alkali by the action of an acid, and a compound (B2) that generates an acid by irradiation with active light or radiation.

[0241] Hereinafter, the resin (A2) whose solubility to alkali increases by the action of an acid is also referred to as "resin (A2)". Moreover, the compound (B2) which generates an acid by irradiation of an active ray or a radiation is also described as "acid generator (B2)".

[0242] Hereinafter, the essential components or optional components contained in the second positive type composition will be descr...

Embodiment 1

[0467] 100 parts by mass of Novolac resin, 13 parts by mass of a sensitizer, 22.6 parts by mass of a quinonediazide group-containing compound, and 27 mass % of a pigment relative to the mass of the total solid content were uniformly dissolved and dispersed in propylene glycol monomethyl In the base ether acetate, the solid content concentration was adjusted to 20% by mass to obtain a positive tone composition.

[0468] It should be noted that in the positive type composition, 1% by mass of 2-hydroxyethylpyridine and 0.4% by mass of silicon-based surfactant ( BYK-310, manufactured by BYK Chemie).

[0469] As the Novolac resin, a cresol-type Novolac resin having a weight average molecular weight of 4700 and a degree of dispersion of 4.5 was used.

[0470] As the sensitizer, a phenolic resin (trade name: TrisP-PA-MF, manufactured by Honshu Chemical Industry Co., Ltd.) was used.

[0471] As a compound containing a quinonediazide group, a product obtained by esterifying 2,3,4,4'-...

Embodiment 2

[0483] The Novolac resin was changed to a cresol-type Novolac resin with a weight average molecular weight of 4700 and a degree of dispersion of 10.0, except that a positive-type composition was prepared in the same manner as in Example 1, and it was operated in the same manner as in Example 1 to obtain A patterned metal layer and a coating resin layer are formed on the substrate.

[0484] The optical density of the formed covering resin layer was 0.60 / μm.

[0485] In addition, when the shape of the formed coating resin layer was observed with a microscope, the top of the pixel was not covered with the coating resin layer, the film thickness of the coating resin layer was substantially uniform, and no exposure of the patterned metal layer was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com