Intelligent flat hair cutting device for rolling brush

A rolling brush, intelligent technology, applied in the field of intelligent flat hair cutting equipment for rolling brushes, can solve the problems of uneven surface, non-uniform cleaning equipment surface, insufficient cleaning, etc., to improve efficiency, save manpower, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

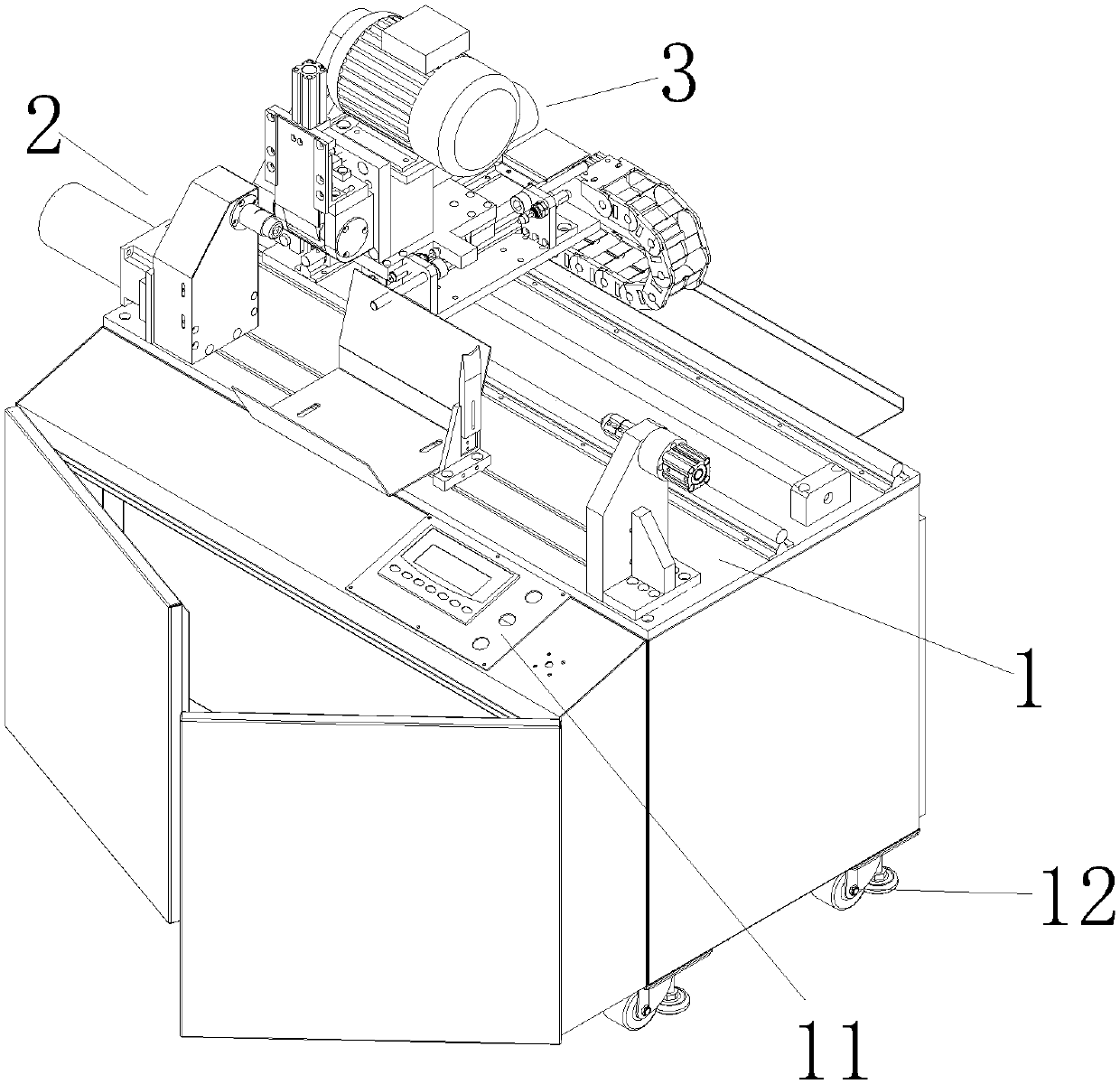

[0036] Such as figure 1 As shown, an intelligent flat-hair cutting equipment for rolling brushes includes a workbench 1 on which a pair of clamping devices 2 for clamping the roll brushes and a pair of clamping devices 2- The cutting device 3 for cutting the roller brush sideways is provided with an inclined surface on one side of the workbench, and a control panel 11 is arranged on the inclined surface, and a control system connected with the control panel 11 is arranged inside the workbench 1 and adopts PLC program control, and is located at Universal wheels 12 are provided at the bottom of the workbench 1 .

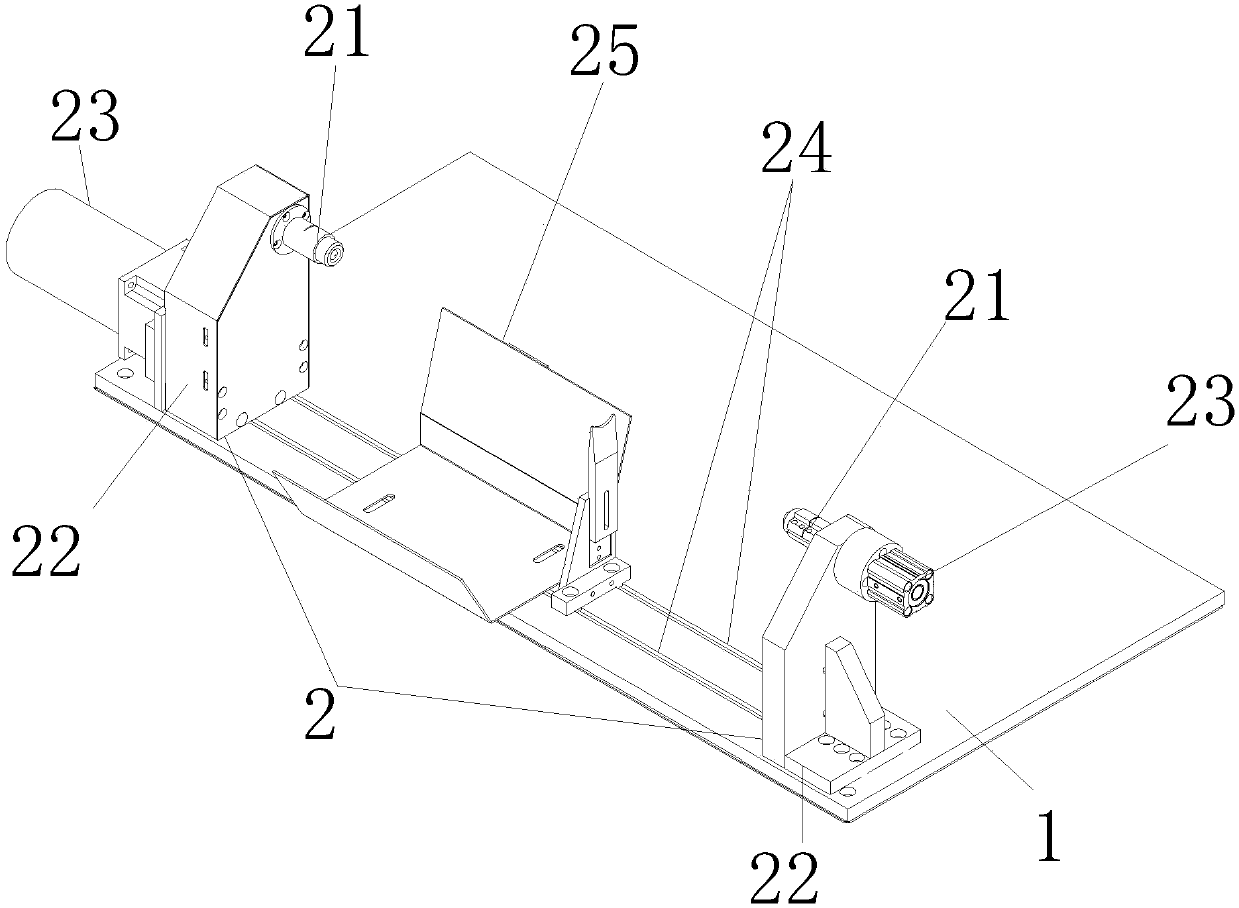

[0037] Such as figure 2 As shown, each clamping device 2 is provided with a clamping shaft 21, and a pair of clamping shafts 21 arranged correspondingly will press the two sides of the roller brush to fix the roller brush, and each clamping shaft 21 passes through the base respectively. 22 is connected with the workbench 1, and each base 22 is respectively provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap