Surgical suture line of winding structure

A technology of surgical suture and wrapping silk, which is applied in the field of surgical sutures, can solve the problems of not being able to completely replace knotting and difficult production, and achieve the effects of saving knotting time, avoiding stitch removal, and relieving pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

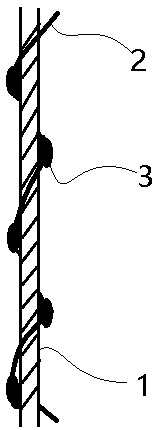

[0035] A surgical suture thread with a wrapping structure, including a core yarn 1 and a wrapping yarn 2, the core yarn 1 is formed by twisting a plurality of filaments, the wrapping yarn 2 has slubs 3 distributed evenly at intervals, and the wrapping yarn 2 wrapped on the core yarn 1; when the wrapped yarn 2 is straightened, the distance between two adjacent thick places 3 on the wrapped yarn 2 is 4-15mm; when the wrapped yarn 2 is wrapped on the core yarn 1 , along the axial direction of the surgical suture, the interval between the two thick nodes 3 is 3-13mm.

[0036] Preferably, the surface of the plurality of filaments constituting the core yarn 1 is concave-convex. This can increase the cohesion between the filaments in the core yarn 1 . At the same time, since the surface of the filament is concave-convex, the wrapping filament 2 is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com