Tourniquet Cuff and method for manufacturing same

A technology of cuff and longitudinal direction, which is applied in the field of manufacturing this kind of tourniquet cuff, can solve the problems of cover folds, garbage generation, unfavorable resource efficiency, and excess materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

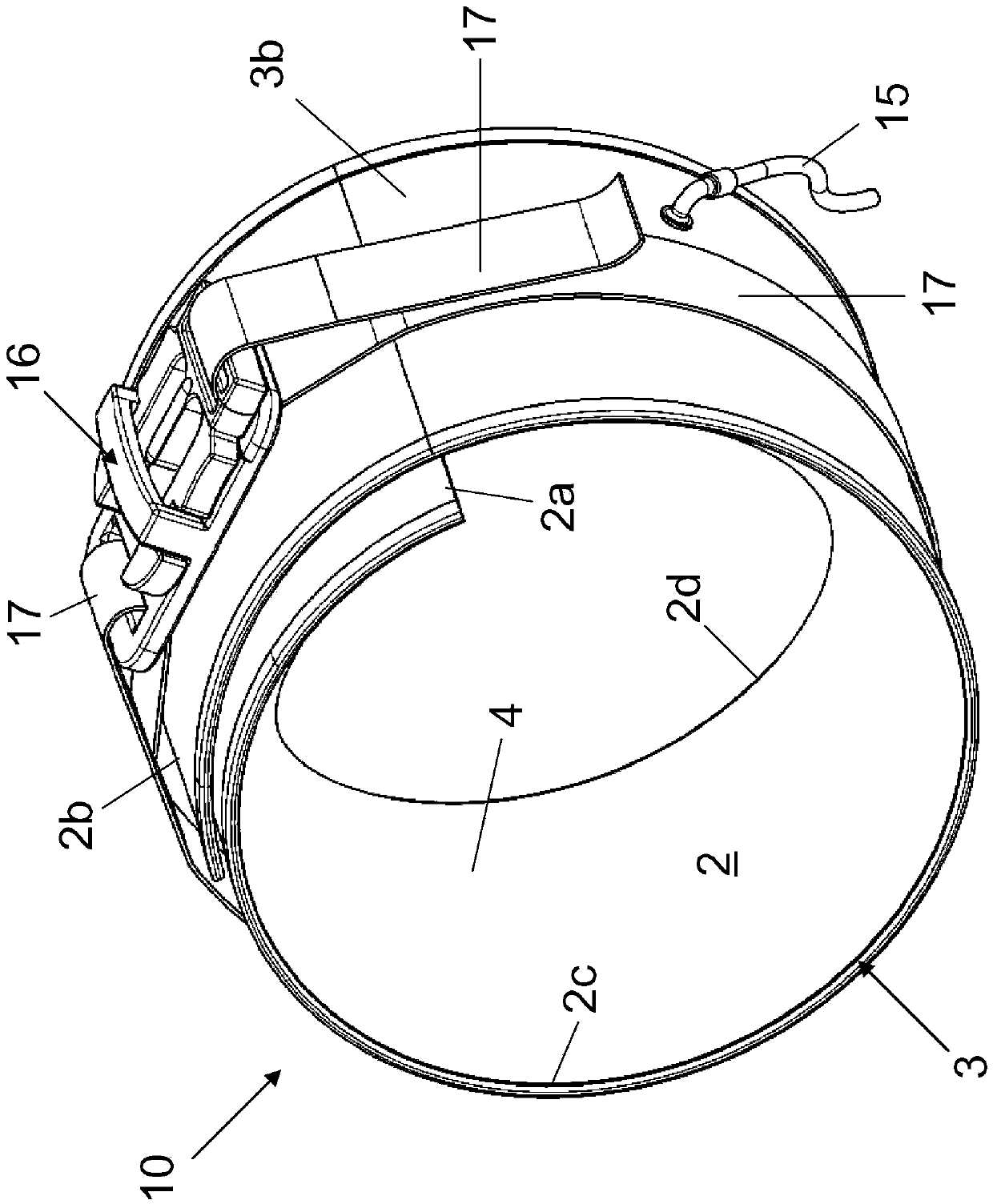

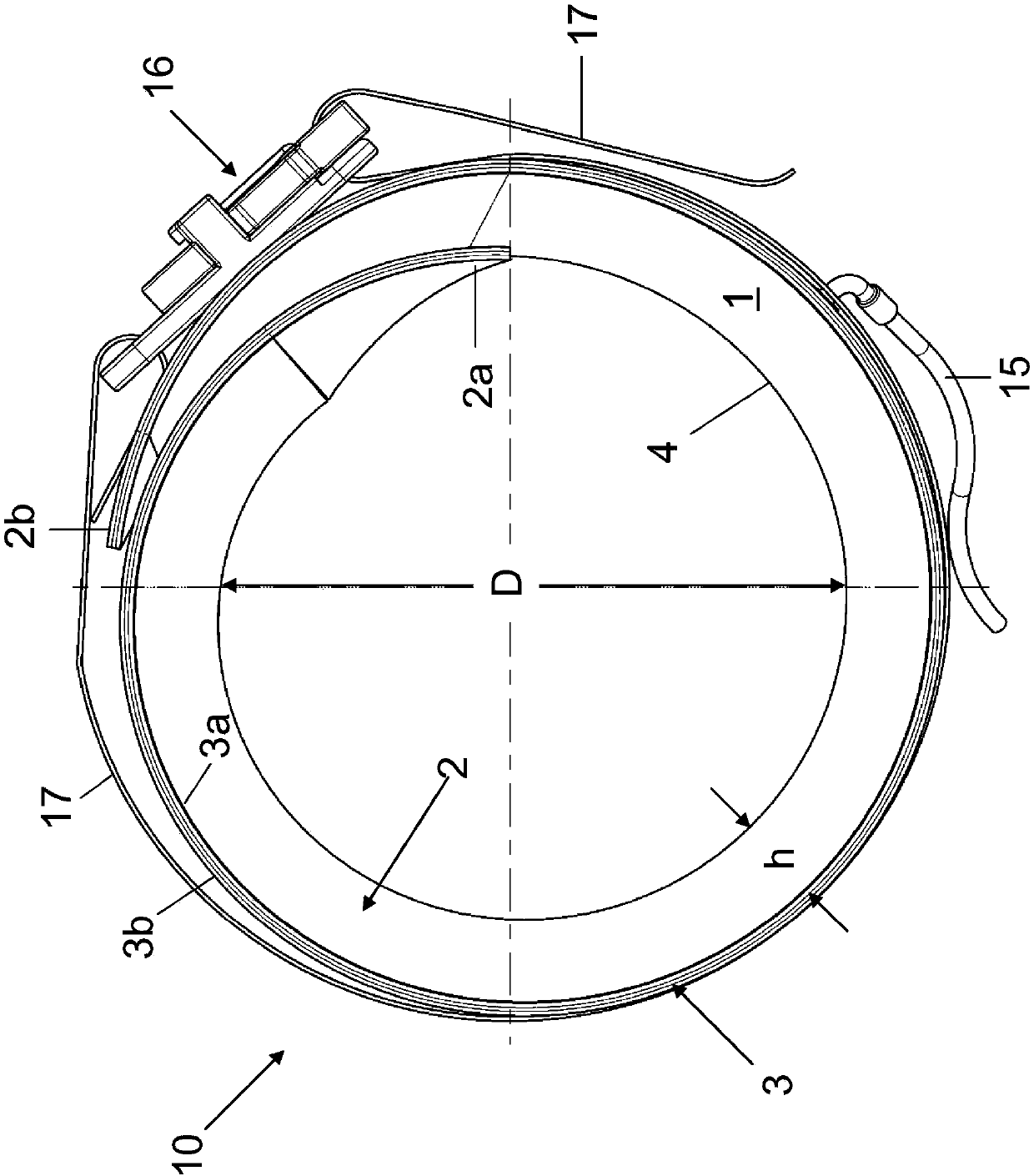

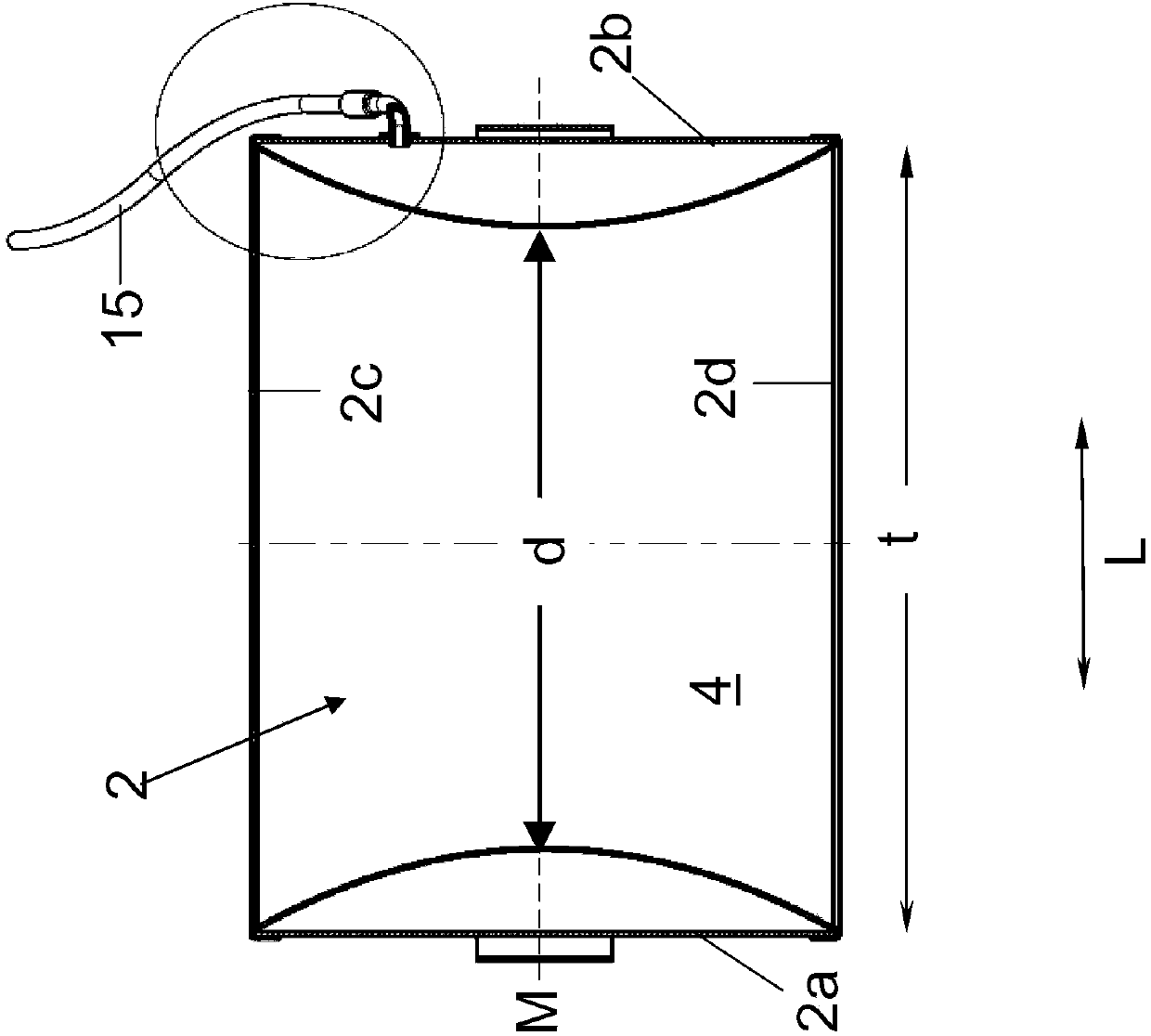

[0029] exist figure 1 and figure 2 A tourniquet cuff 10 according to the invention is shown for placement on a limb. The tourniquet 10 comprises an inflatable body 2 which surrounds an air-tight inflatable chamber 1 . The inflation body 2 can be connected to a compressed gas source (not shown here) via a line 15 connected to the inflation chamber 1 . The source of compressed gas can be, for example, a compressor which supplies compressed gas, in particular compressed air, with which the inflation body can be inflated. The pressure for inflating the inflation body 2 is controlled here via a control unit contained in the pressure source. Such a control unit for controlling a tourniquet cuff is known from the prior art. A closure strip 17 with a closure 16 is fastened on the outside of the inflatable body 2 . The closure strip 17 can be fixed in the desired position by means of the closure element 16 designed here as a snap button, in order to be able to secure the tourniqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com