Manufacturing equipment and preparation method of multifunctional modified aromatic hydrocarbon

A manufacturing equipment, multi-functional technology, applied in chemical instruments and methods, dissolving, mixers, etc., can solve the problem of uneven dispersion, inability to continuously complete ultra-fine grinding, classification and separation, and inability to continuously complete multi-functional modification Aromatics etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The invention relates to a manufacturing equipment of multifunctional modified aromatics, which includes a refining unit and a homogenizing unit.

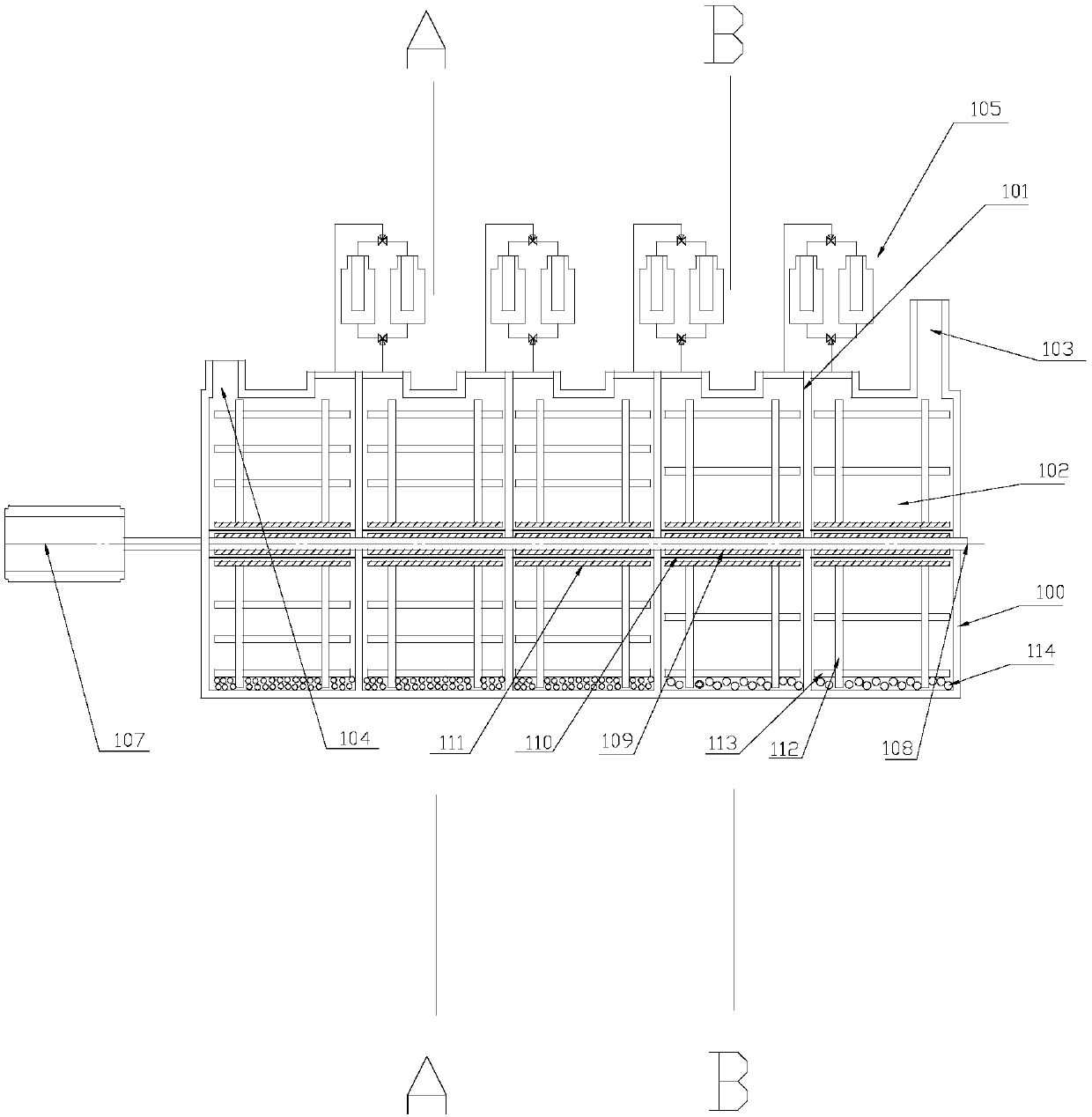

[0054] Among them, such as figure 1 As shown, the refinery device includes a laterally arranged cylindrical refinery cylinder 100 and a stirring mechanism.

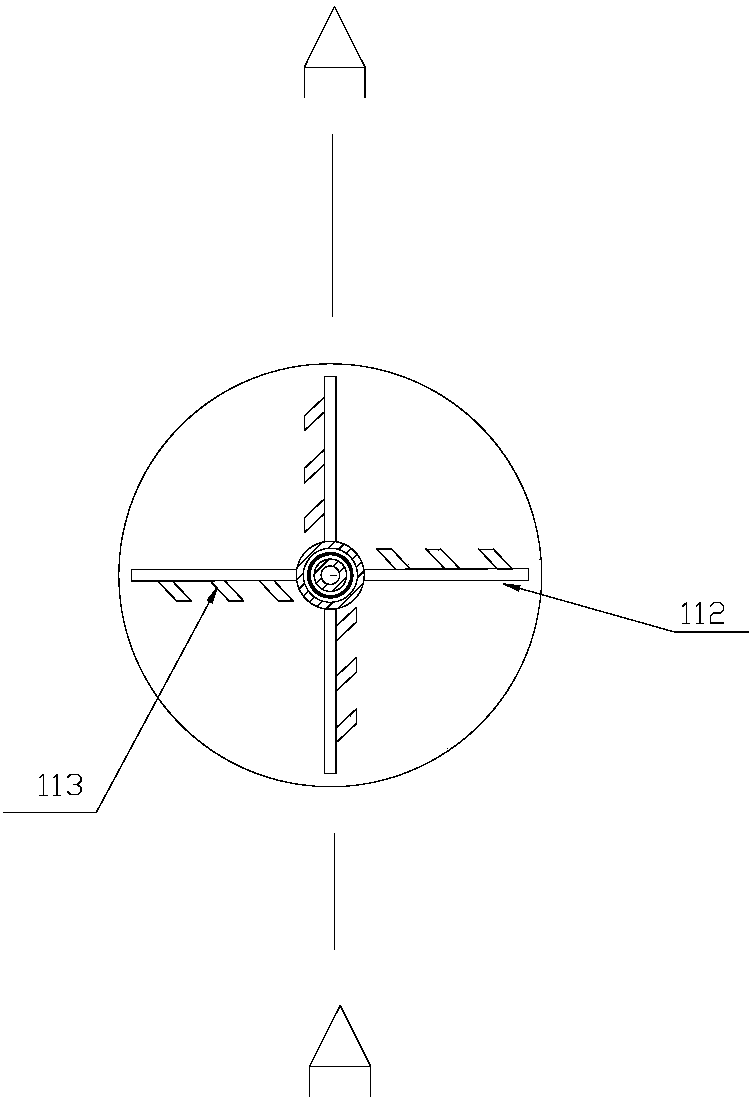

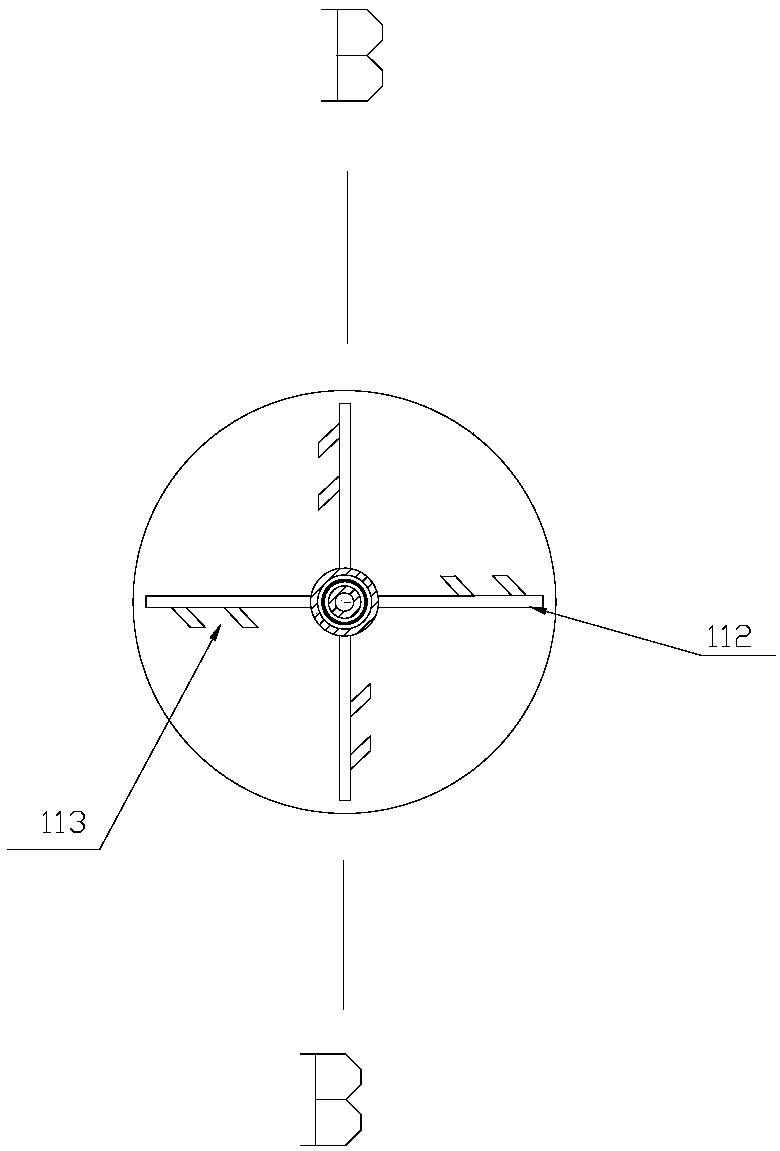

[0055] The refinery cylinder is divided into five refinery chambers 102 by partitions 101 in the axial direction, and the five refinery chambers are sequentially denoted as refinery chambers I to V according to the material flow direction, and the top of the refinery chamber I is respectively A feed port 103 is provided, and a discharge port 104 is provided on the top of refining chamber V. Adjacent refining chambers are connected by pipelines, and two parallel column filters 105 are arranged on the pipelines; like Figure 4 As shown, the cross-section of the filter net is toothed and annular. The mesh of the filter screen decreases in order according to the directi...

Embodiment 2

[0063] A method for preparing multifunctional modified aromatic hydrocarbons, using the manufacturing equipment of Example 1, first preparing the multifunctional modified aromatic hydrocarbon mother liquor from aromatic hydrocarbons containing modifiers through refining and chemical equipment, and then mixing the multifunctional modified aromatic hydrocarbon mother liquor with aromatic hydrocarbons Preparation of multifunctional modified aromatics by homogenization device.

[0064] The preparation method is specifically:

[0065] Aromatics containing modifiers are continuously transported from the feed port of the refinery unit to refinery chamber I by branch pipe metering pumps. In refinery chamber I, aromatics and modifiers, under the action of medium balls and stirring mechanisms, Refining, and then transported through the column filter to the refining room of the next level for more refined refining, and finally discharged from the outlet of the last level of refining room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com