System and method for coal tar gas production by coupling of pulverized coal pyrolysis and dust removal

A coal tar and pyrolysis technology, which is applied in gas dust removal, coke cooling, coke oven, etc., can solve problems such as reducing coal tar yield and changing pyrolysis residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

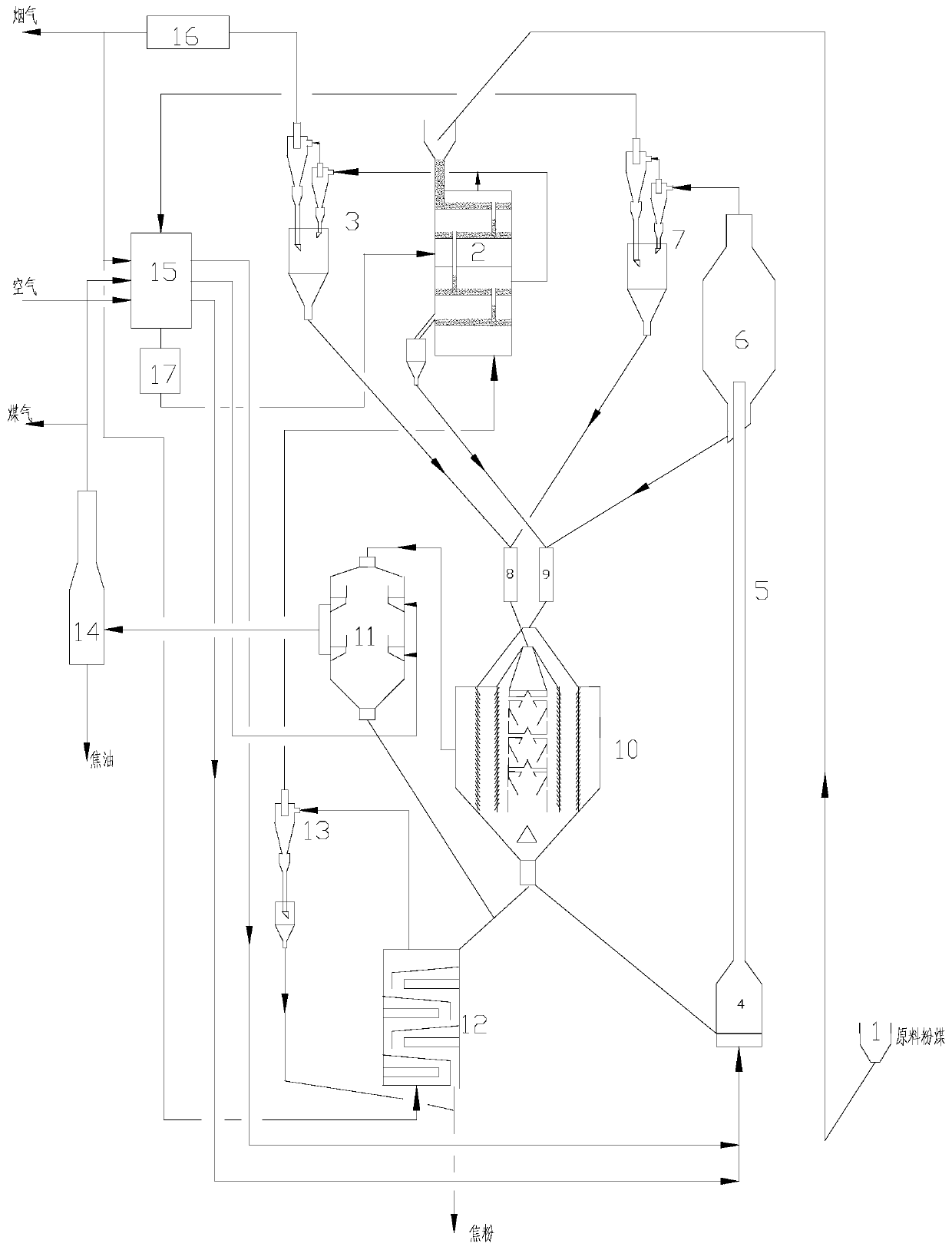

[0065] see figure 1 , the present invention provides a system for producing coal tar gas by coupling pulverized coal pyrolysis and dust removal, the system for producing coal tar gas by coupling pulverized coal pyrolysis and dust removal includes a drying unit, a circulating semi-coke heating unit, unit, coke cooling unit and oil washing unit;

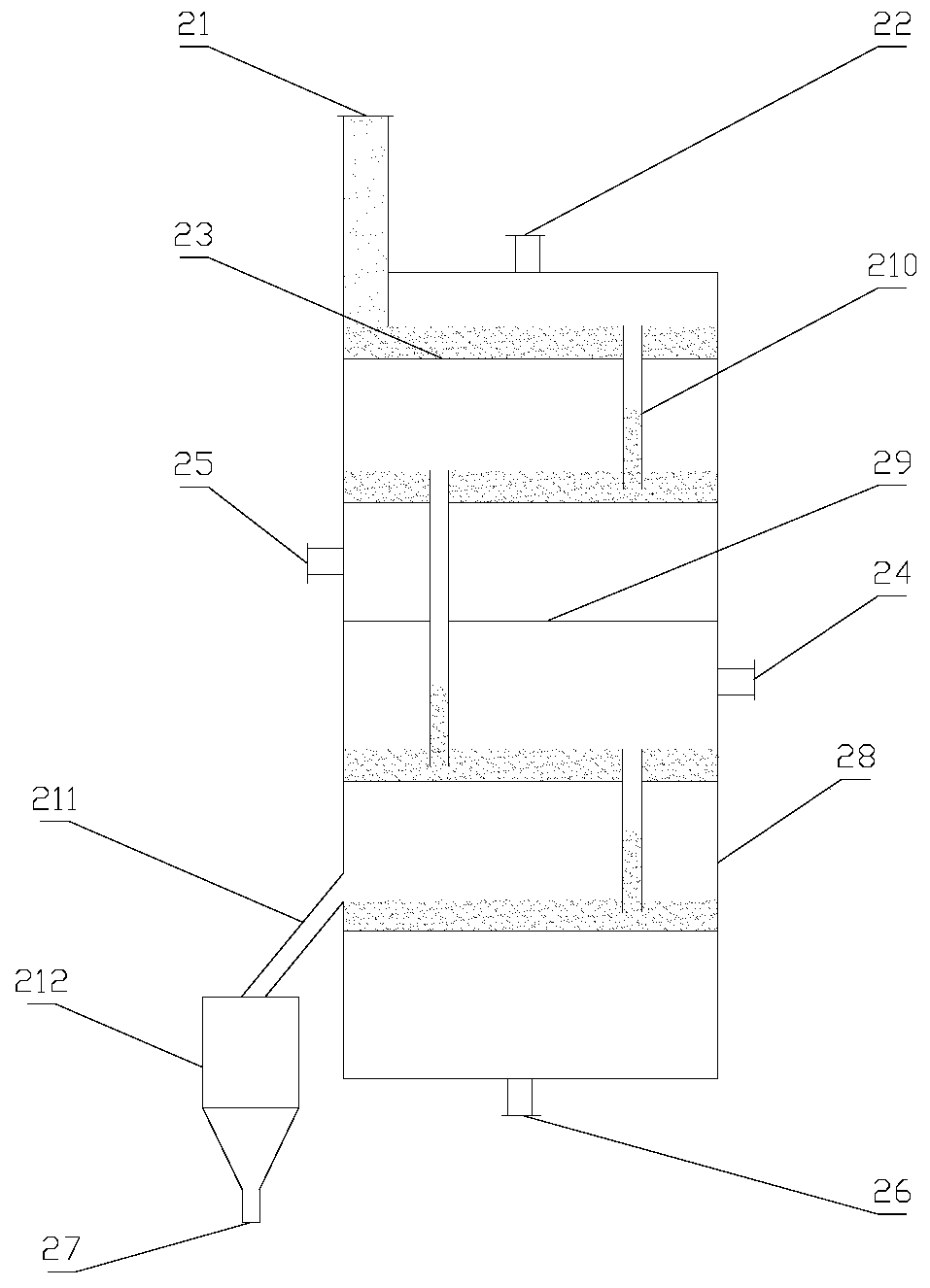

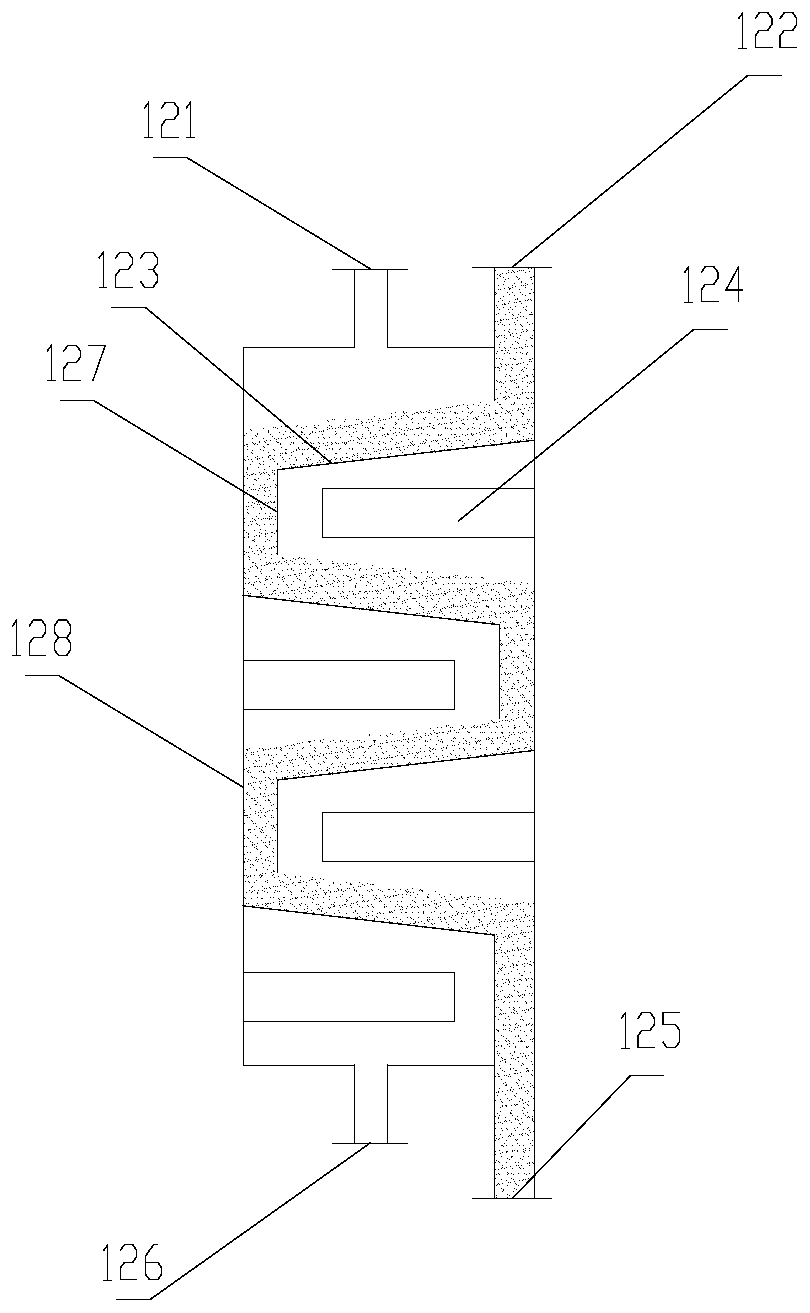

[0066] Drying unit, including multi-stage fluidized bed drying classifier 2 and dry coal combined cyclone dust collector 3, raw coal bunker 1 is connected with multi-stage fluidized bed drying classifier 2, multi-stage fluidized bed drying classifier 2 is connected with dry Coal combined cyclone dust collector 3 connected, see figure 2 , the multi-stage fluidized bed drying classifier 2 of the present embodiment comprises a classifier box body 28, and a partition plate 29 is arranged in the classifier box body 28, and the classifier box body 28 is successively divided into interconnected parts from top to bottom. In the upper drying...

Embodiment 2

[0104] A kind of fluidized bed drying classifier provided in this embodiment, the distribution plate 23 in the upper section drying zone and the distribution plate 23 in the lower section drying zone of the fluidized bed drying classifier are two layers; the distribution plate in the upper section drying zone The plate 23 has 3 layers, and divides the upper drying area into 4 parts from top to bottom, while the distribution plate 23 in the lower drying area has 2 layers, and divides the lower drying area into 3 parts. The distribution plate 23 and the adjacent distribution plate 23 The dry coal drying overflow pipe 210 communicates between them, and the upper drying area and the lower drying area are separated by a partition plate 29. The distance between the inlet of the drying overflow pipe 210 and the upper surface of the upper distribution plate 23 is 100 mm, the bottom extends to the distribution plate 23 at the bottom and the distance from the upper surface of the distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com