Temperature correcting mold for spark plasma sintering

A discharge plasma and mold technology, which is applied in the field of temperature calibration molds, can solve the problems of sample melting, temperature measurement errors, and increased experimental costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

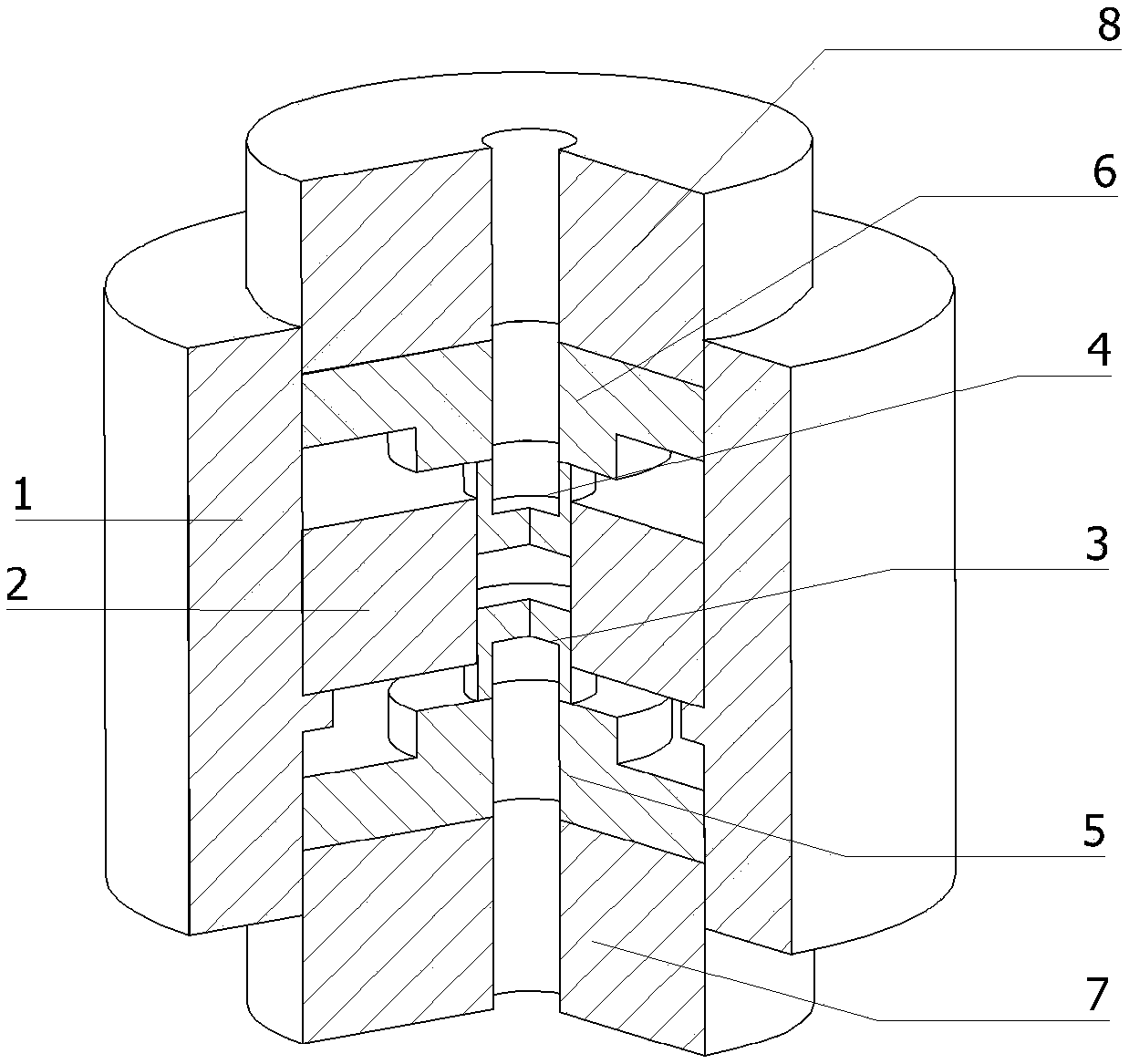

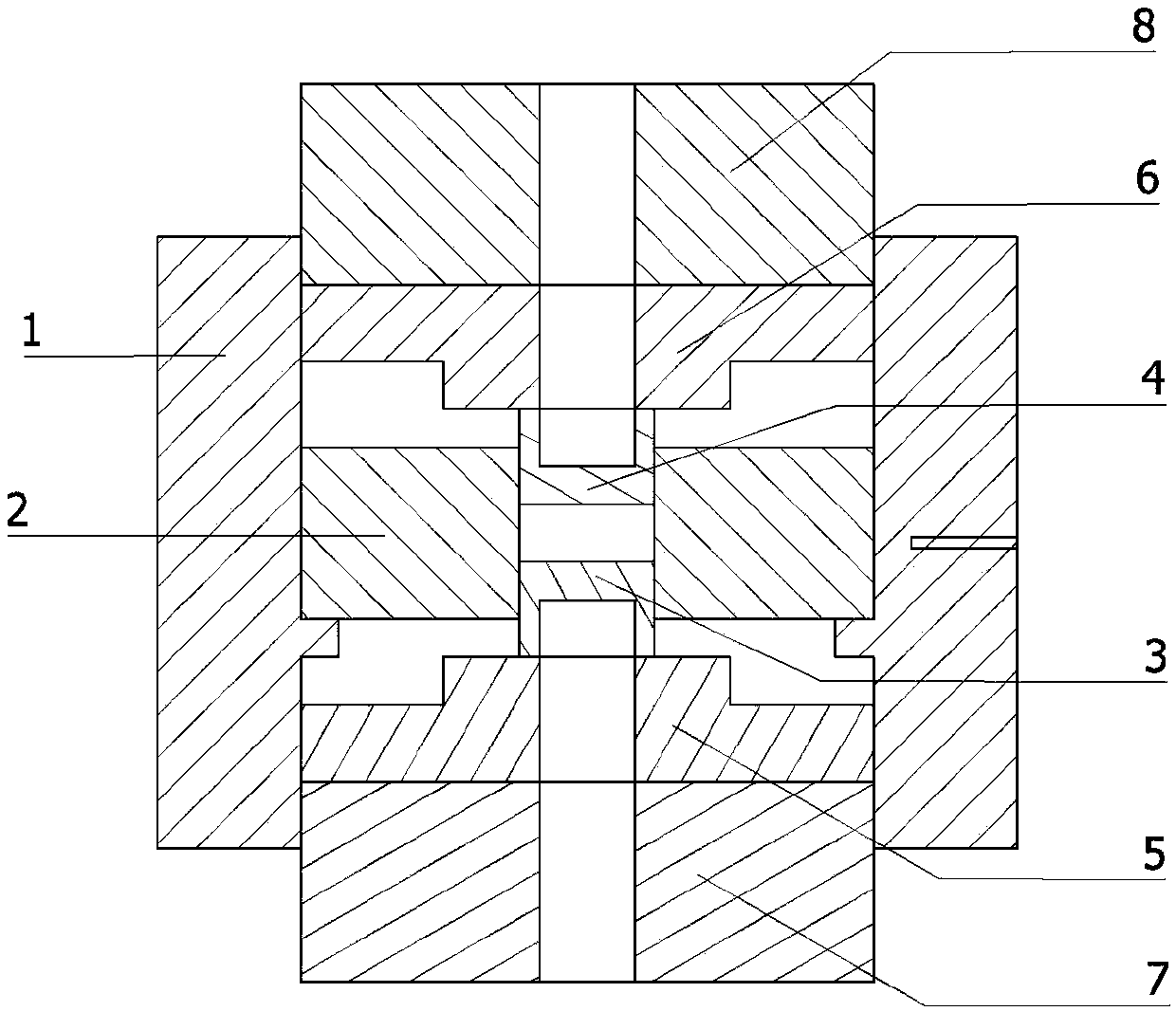

[0021] This embodiment is a temperature calibration mold for spark plasma sintering. The prepared nanocrystalline powder is placed in the sintering area formed by the inner mold, the upper inner pressure head and the lower inner pressure head to ensure that the powder is tightly packed in the sintering area. When working, place the whole set of molds in the discharge plasma sintering equipment, turn on the thermocouple temperature measurement and infrared temperature measurement at the same time, and turn on the electricity to make the whole mold heated up evenly, and at the same time, the pressure acts on the outer pressure head. The block is pushed to move to the inside of the mold, the force is transmitted through the steps, and finally the pressure is applied to the powder sample, so that the powder sample is sintered under pressure. Observe the temperature measured by infrared rays and thermocouples during the sintering process. When the temperature measured by infrared r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com