Laser cutting machine

A cutting machine, laser technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of irritating odor harmful to human body and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

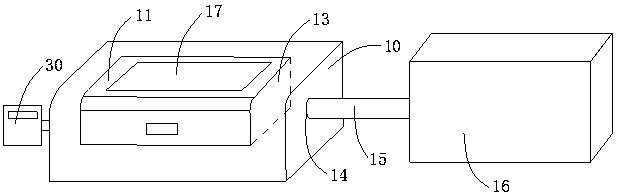

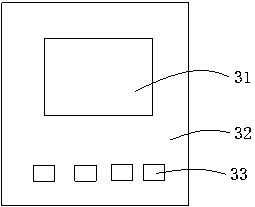

[0015] see figure 1 and figure 2 , a laser cutting machine, including a housing 10 and a cover plate 11 connected to the housing 10, the upper part of the housing 10 is provided with an opening facing the front and the upper part, forming a cutting work space 13 facing the front and the upper opening , when the cover plate 11 covers the housing 10, an airtight cutting work space 13 is formed, and an air outlet 14 communicating with the cutting work space 13 is provided on the housing, and the air outlet 14 is connected to a connecting pipe 15 through a The cleaning device 16 is connected. The purification device 16 can be selected as a conventional industrial purification and dust removal machine, which can purify and remove the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com