Adjusting device used for welding of landscape pillar steel reinforcement cage

The technology of a column and a support column is applied in the field of adjustment devices for welding of steel skeletons of landscape columns. Ensure welding stability and reduce the effect of mutual collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

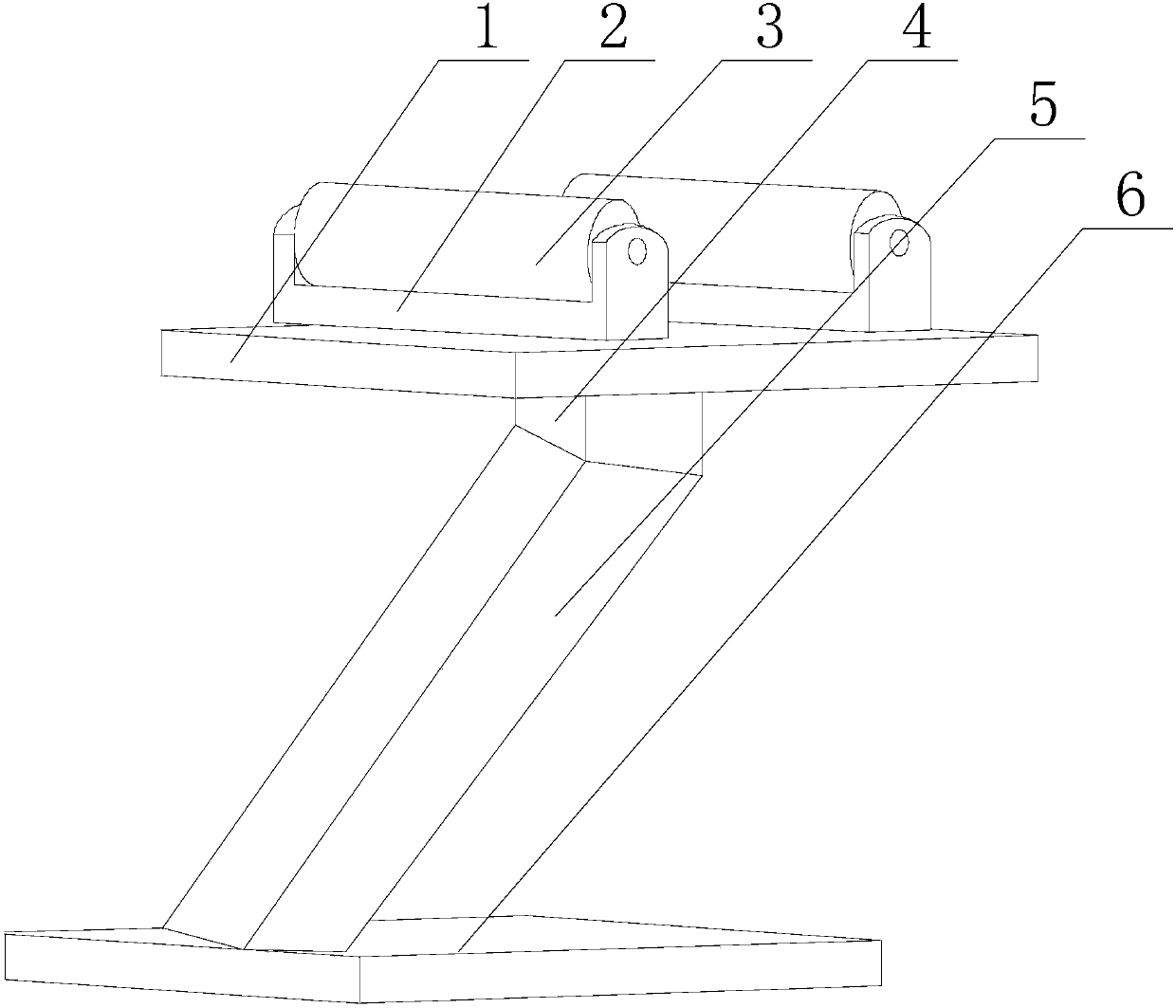

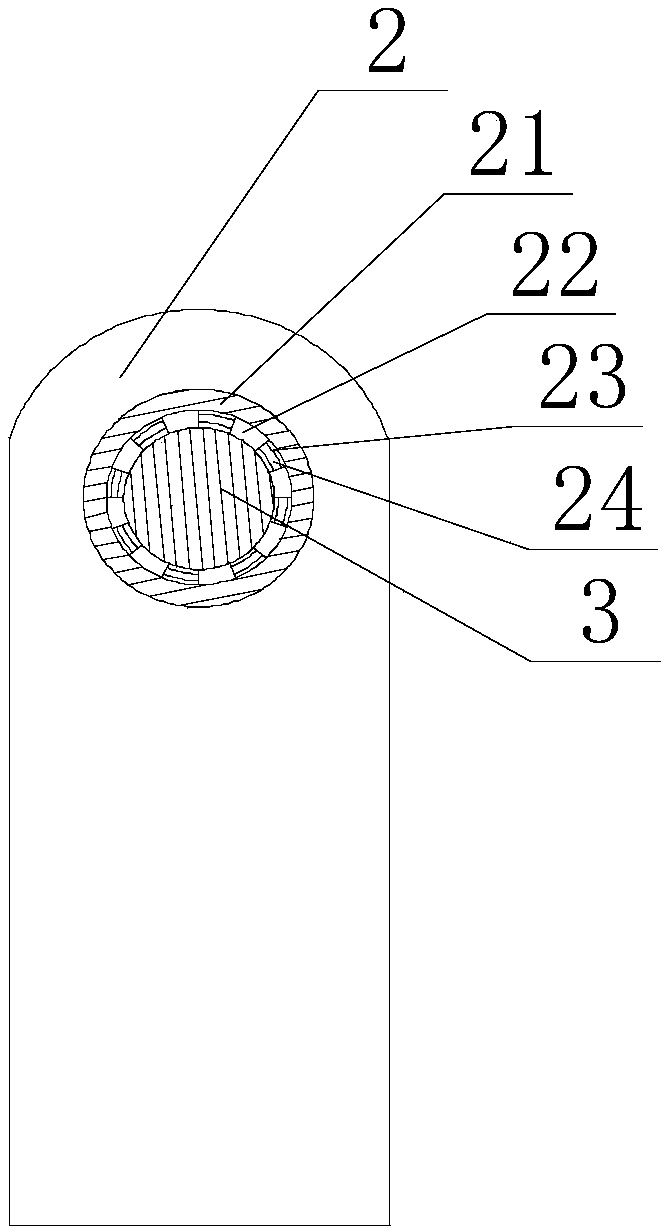

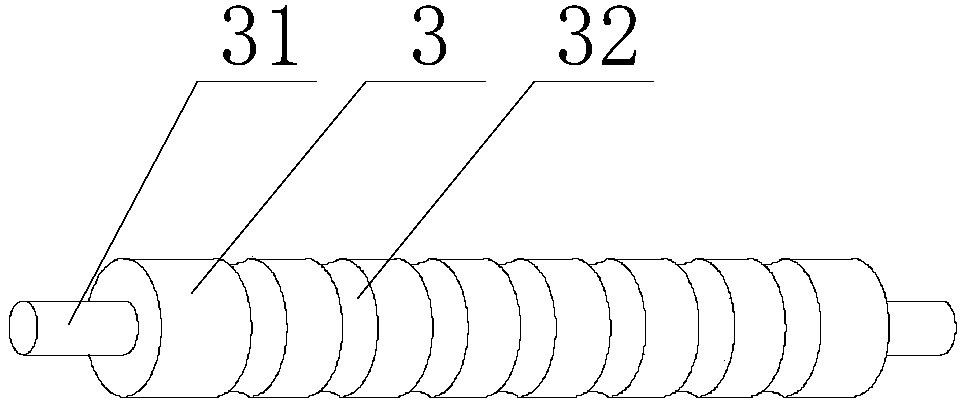

[0023] like Figure 1~3 As shown, this embodiment includes a turntable 6 and a mounting plate 1. A support column 5 is provided on the turntable 6. The support column 5 is arranged obliquely and forms an included angle with the horizontal line. The value of the included angle is 45°-60° °, a column 4 perpendicular to the horizontal plane is fixed on the upper end of the support column 5, the mounting plate 1 is fixed on the column 4, and at least one mounting seat 2 is arranged on the upper surface of the mounting plate 1, and the two ends of each mounting seat 2 are respectively A fixed plate is provided with a mounting hole, the bearing 21 is embedded in the mounting hole, and an annular space 23 is provided between the outer peripheral wall of the rotating shaft of the conveying roller 3 and the inner peripheral wall of the bearing 21, which is the same as the bearing 21. The connecting ring 24 of the shaft is placed in the annular space 23, and a plurality of sliders 22 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com