Paper cutting device for printing machine

A technology for paper cutting devices and printing machines, applied in transportation and packaging, metal processing, winding strips, etc., can solve the problems of low work efficiency and small application range, and achieve high work efficiency, wide application range, and improved The effect of paper cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

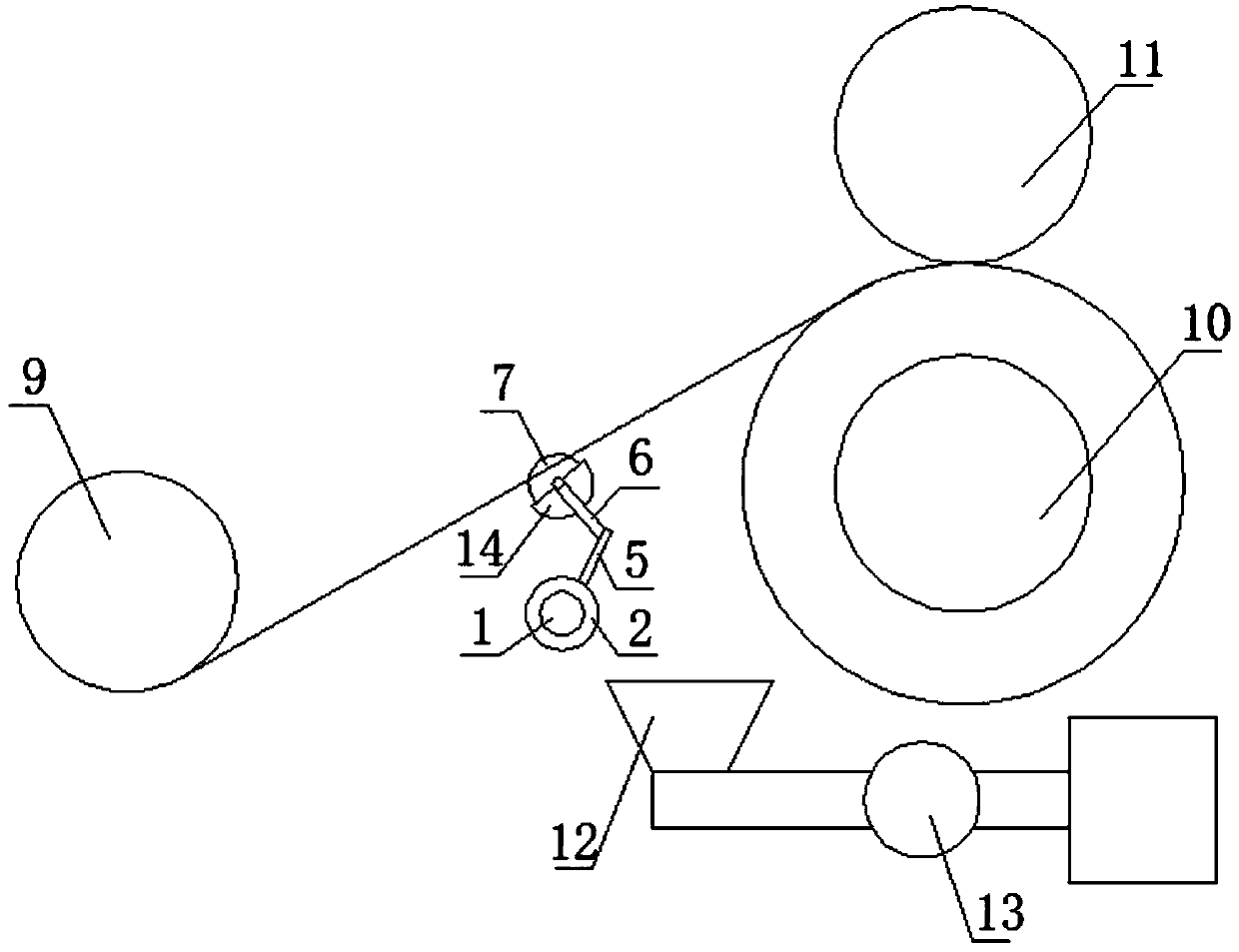

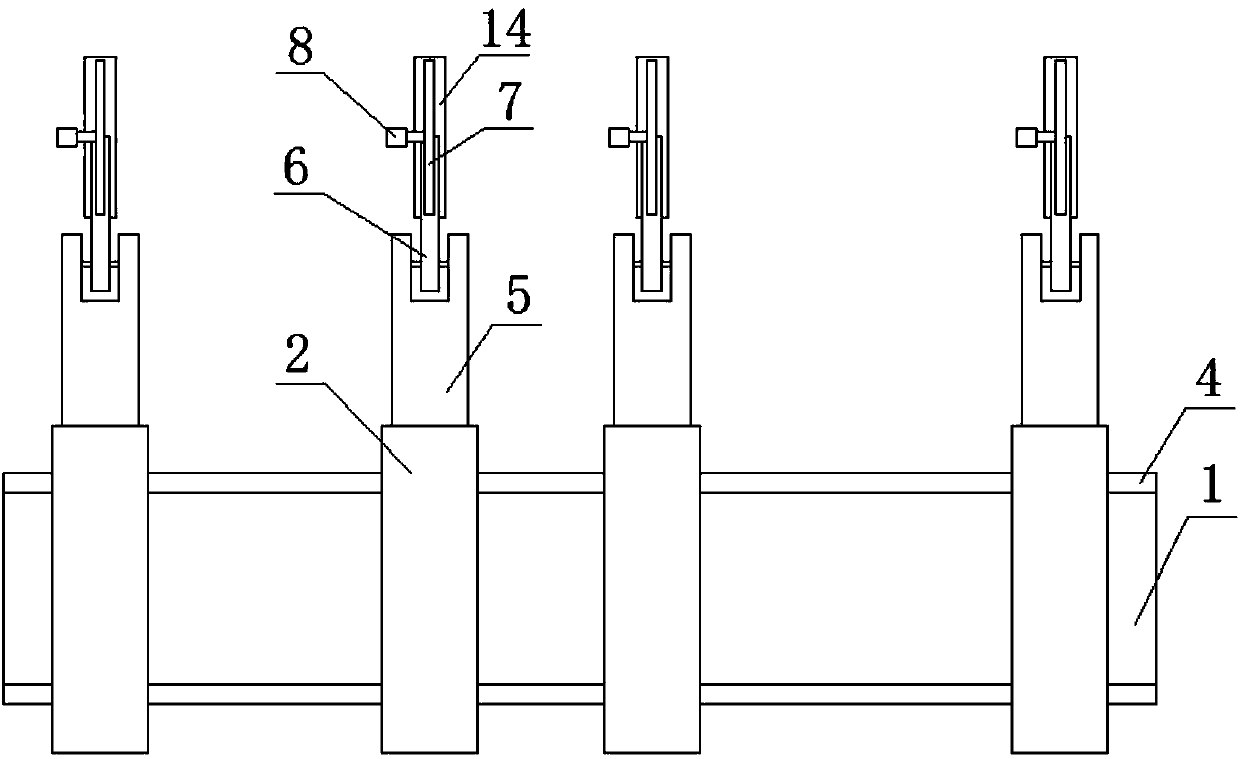

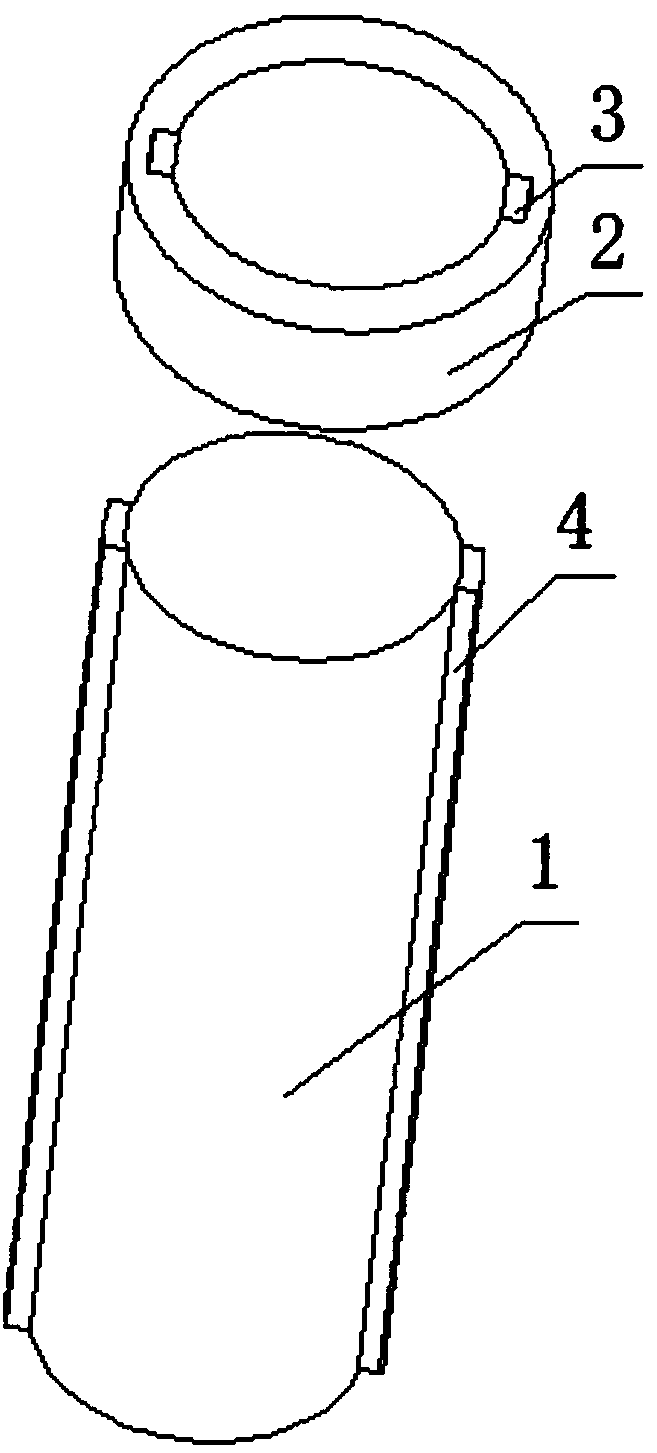

[0013] Example. A paper cutting device for a printing machine, constituted as Figures 1 to 3 As shown, it includes a polished rod 1, a plurality of collars 2 are sleeved on the outside of the polished rod 1, and a groove 3 is provided on the inner side of each collar 2; The grooves 3 cooperate with each other; the collar 7 is connected with a support rod 5, and the top of the support rod 5 is hinged with a connecting rod 6; the connecting rod 6 is connected with a cutter head 7, and the middle part of the cutter head 7 is connected with a motor 8, which is connected to The rod 6 is fixedly connected; the polished rod 1 is provided with a paper guide roller 9 on one side, a paper roll 10 on the other side, and a pressure roller 11 above the paper roll 10 .

[0014] A funnel-shaped waste paper coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com