Straw compression device capable of adjusting moulding size

A technology of straw and forming holes, which is applied in the direction of material forming presses, presses, dust removal, etc., can solve the problems of reducing production efficiency and inconvenience, and achieve the effect of reducing powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

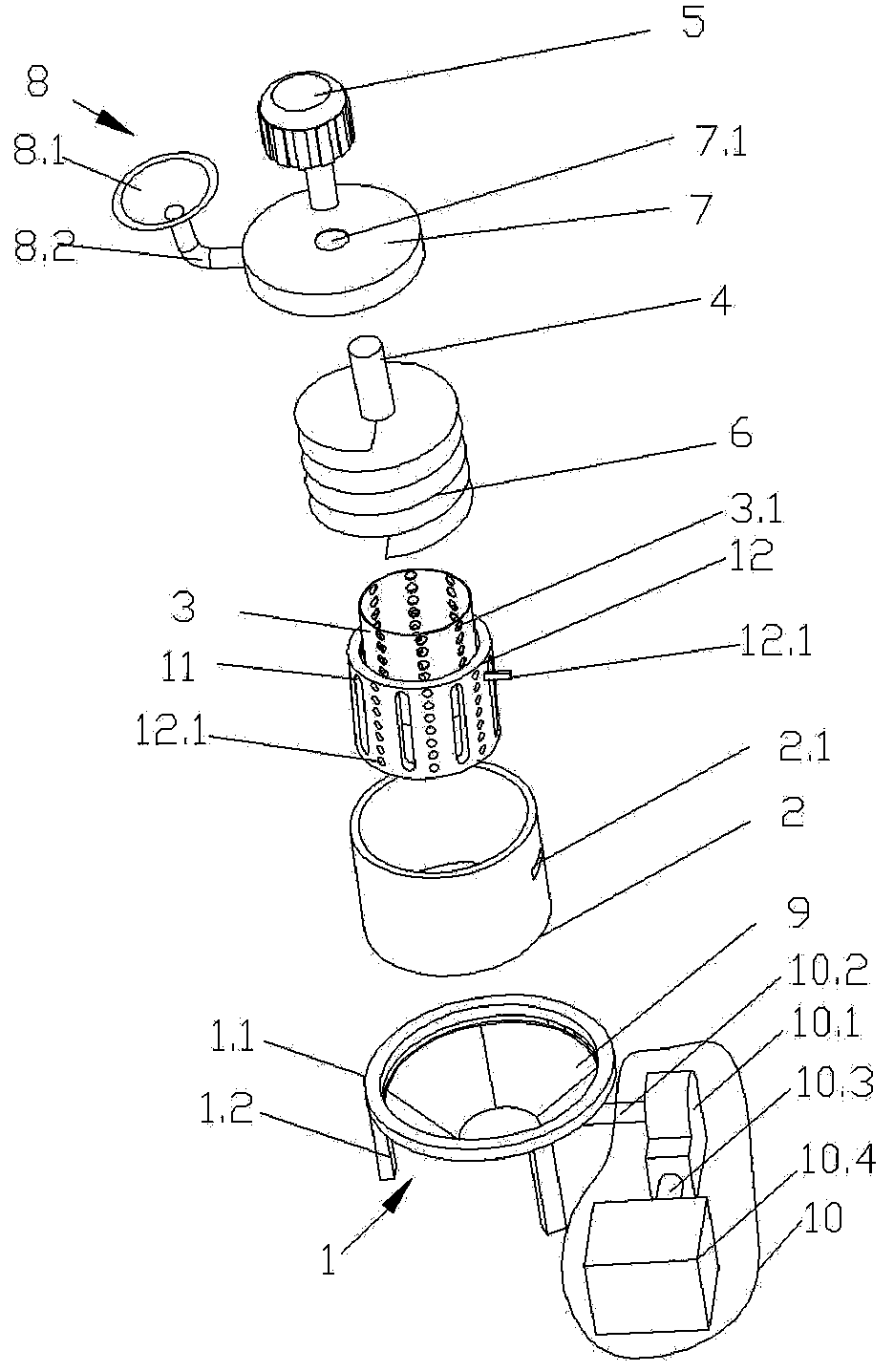

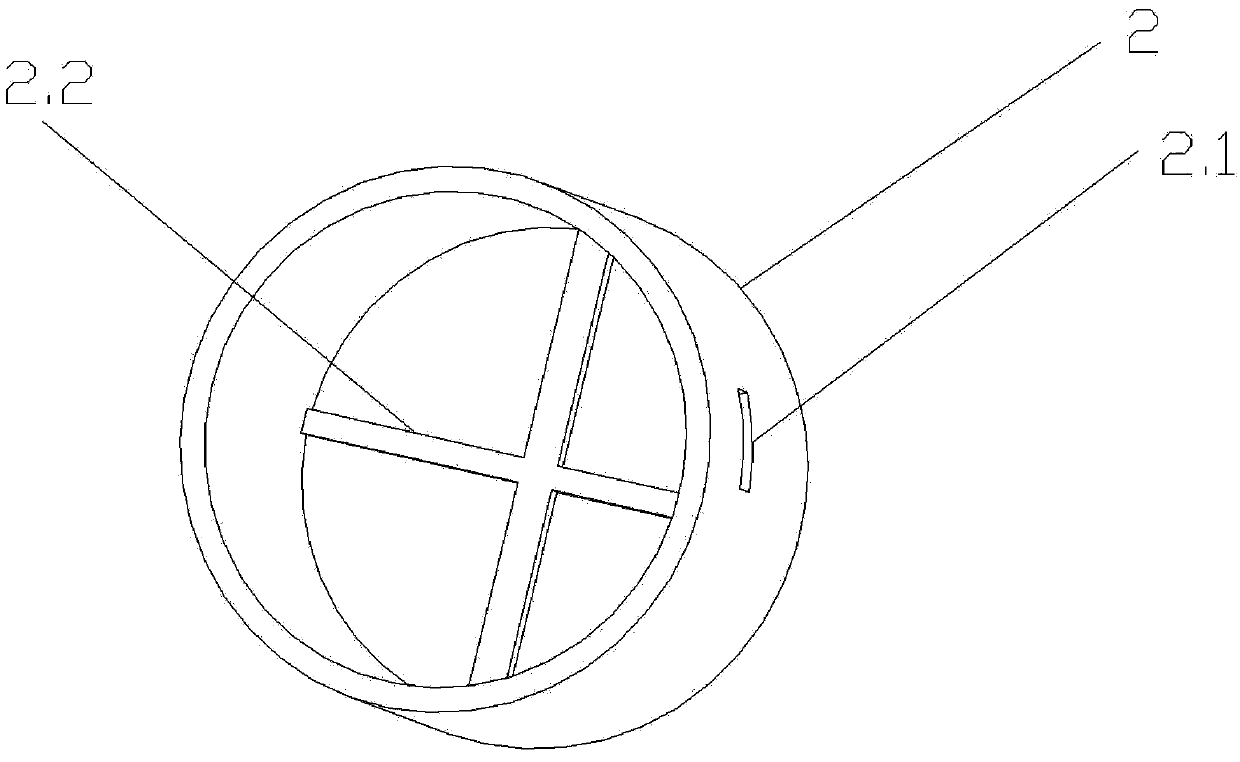

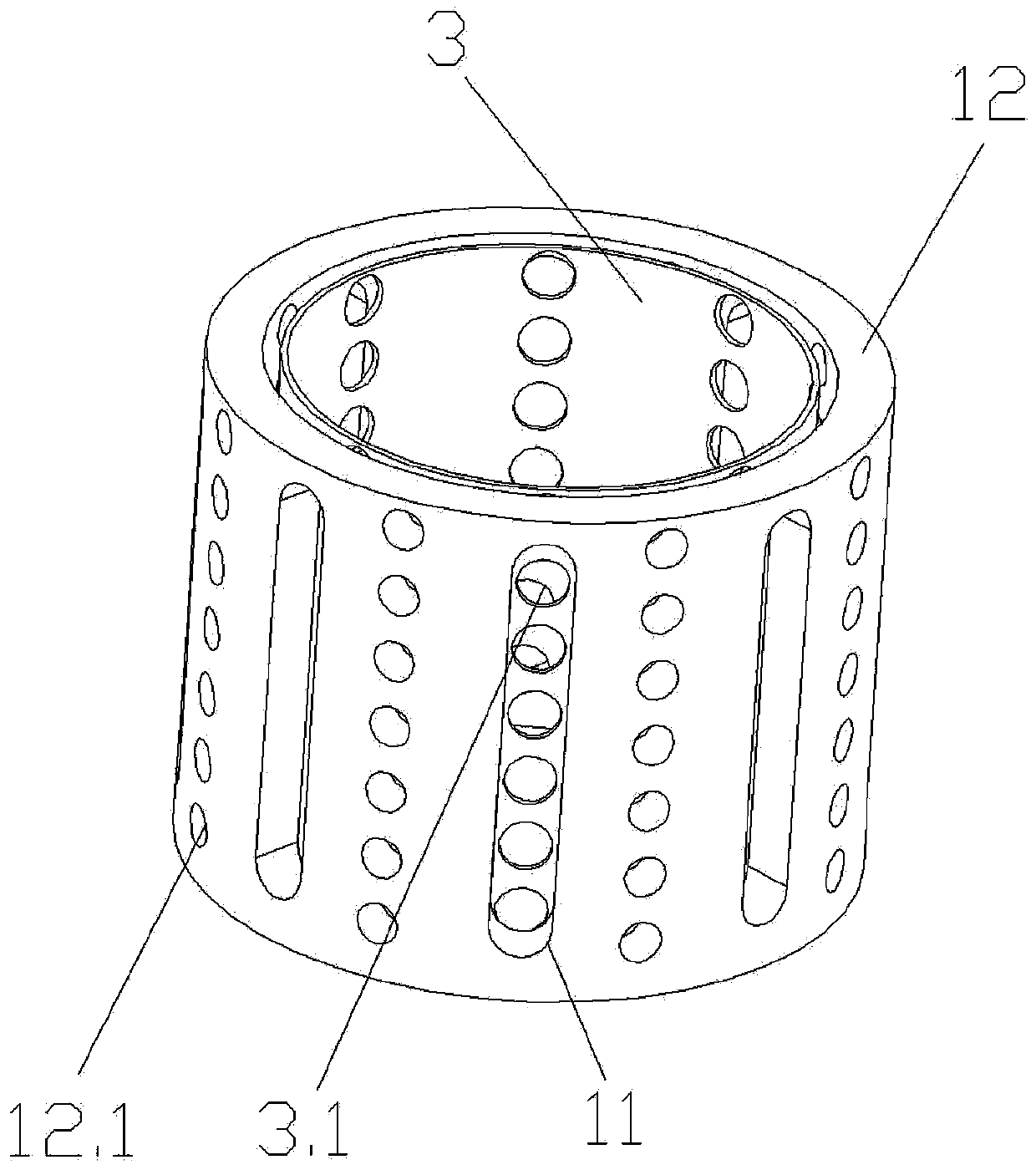

[0020] Such as figure 1 As shown, the present invention provides a straw briquetting device for adjusting the forming size, which is characterized in that it includes a support 1, which includes a ring 1.1, and three rectangular support rods 1.2 are evenly arranged on the lower side of the ring 1.1. The upper side is fixedly connected to the heating tube 2, and the first drum 3 is arranged inside the heating tube 2. Eight rows of first molding holes 12.1 for straw molding are evenly distributed on the outer wall of the first drum 12, and the outside of the first drum 12 is also used for connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap