Electric car wheel-side reducer assembly structure and control method thereof

A technology for the wheel and assembly structure of electric vehicles, applied in the direction of control devices, motion deposition, power devices, etc., can solve problems such as inability to accurately control the driving force, and achieve improved vehicle passing performance, high transmission efficiency, and improved power transmission efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

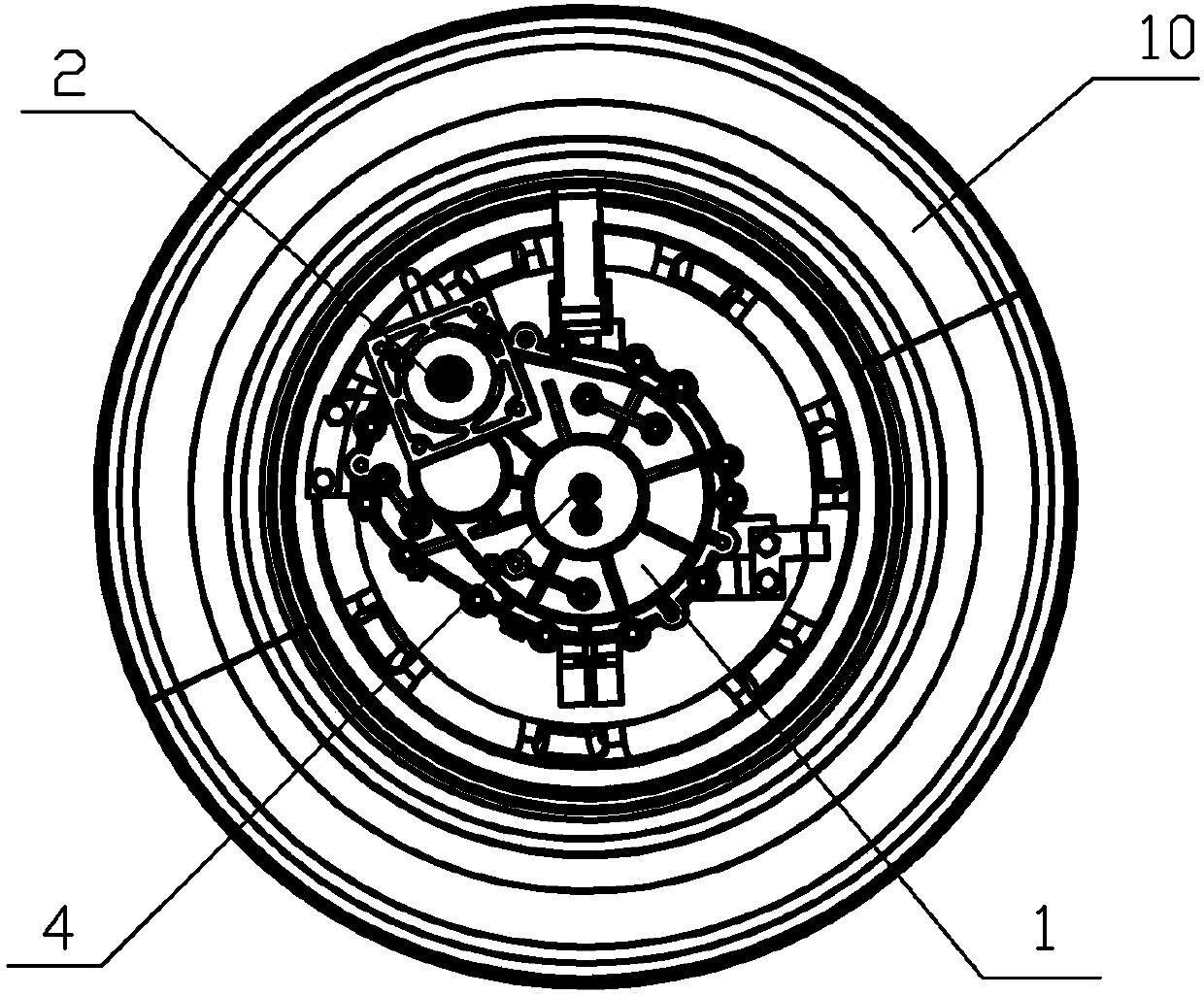

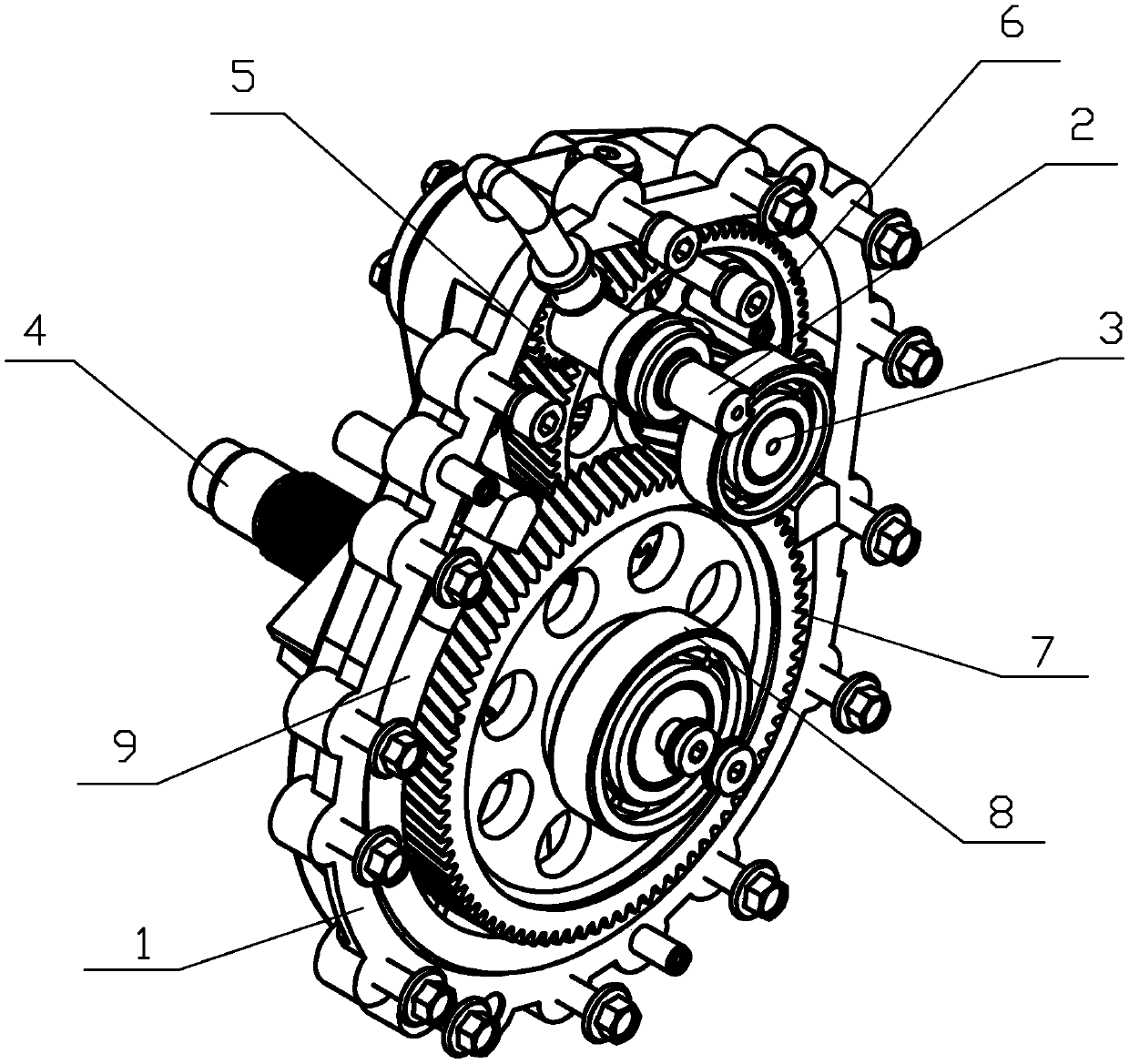

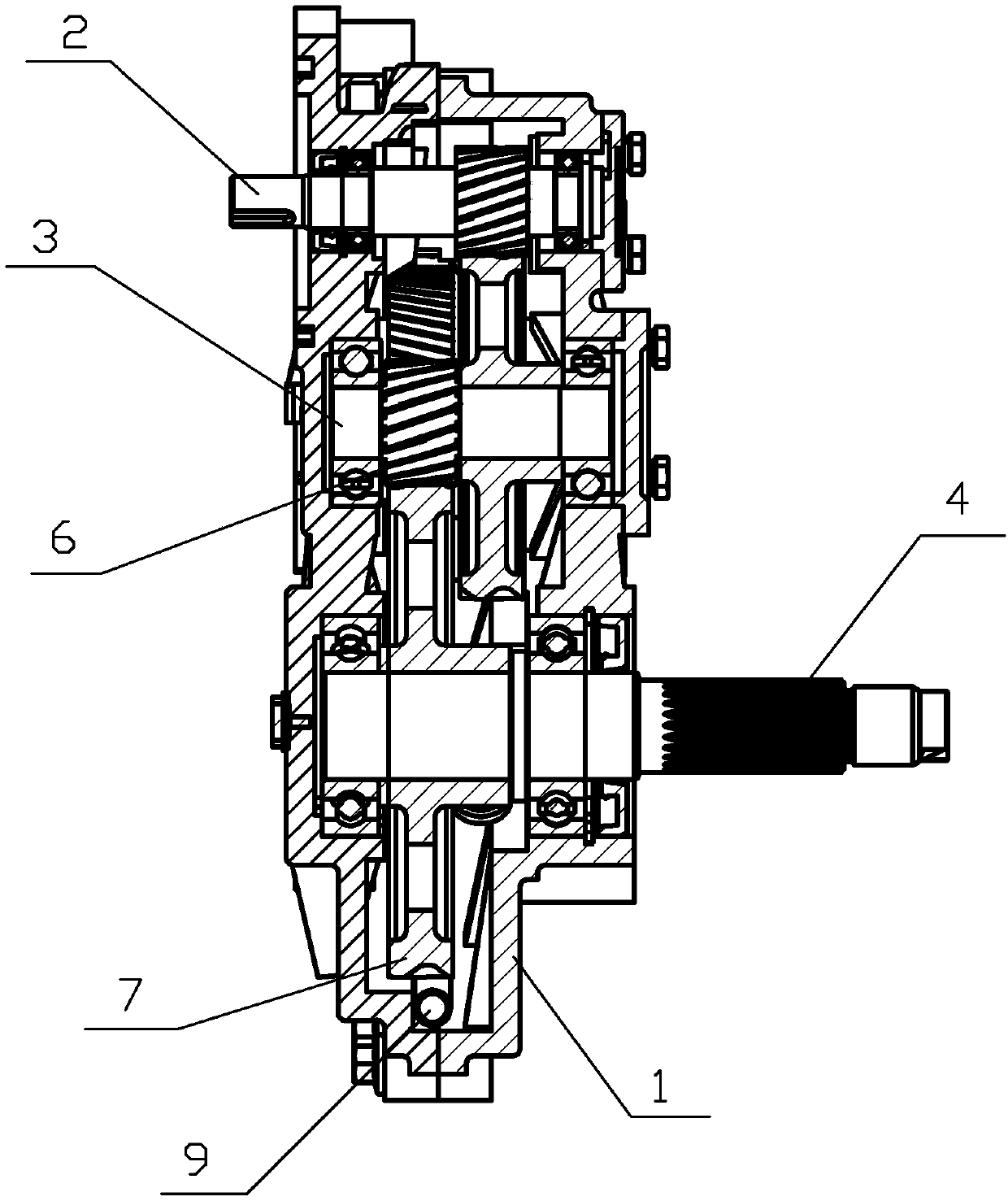

[0018] Example: The structure of the wheel reducer assembly of the electric vehicle in this example is as follows: figure 1 , figure 2 , image 3 As shown, it includes a box body 1 and an input shaft 2, an intermediate shaft 3 and an output shaft 4 installed in the box body 1. The box body is formed by connecting the front side box body and the rear side box body, and one end of the input shaft 2 protrudes out. In the front case, one end of the output shaft 4 protrudes from the rear case, the input shaft 2, the intermediate shaft 3 and the output shaft 4 are distributed in a triangular structure, the distance between the input shaft 2 and the output shaft 4 is 120mm, and the input shaft 2 An input gear 5 is installed on it, an intermediate gear 6 is installed on the intermediate shaft 3, and an output gear 7 is installed on the output shaft 4. The input gear 5 and the output gear 7 mesh with the intermediate gear 6 respectively. The input gear 5, the output gear 7 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com