Connecting structure integrating thermal protection with finished component mounting

A connection structure and component technology, applied in the field of aircraft component installation and connection structure, can solve the problems of difficulty in machining process and assembly process, inconvenient repair, and lengthening product development cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The connection structure of the present invention will be described in detail below with reference to the drawings and embodiments.

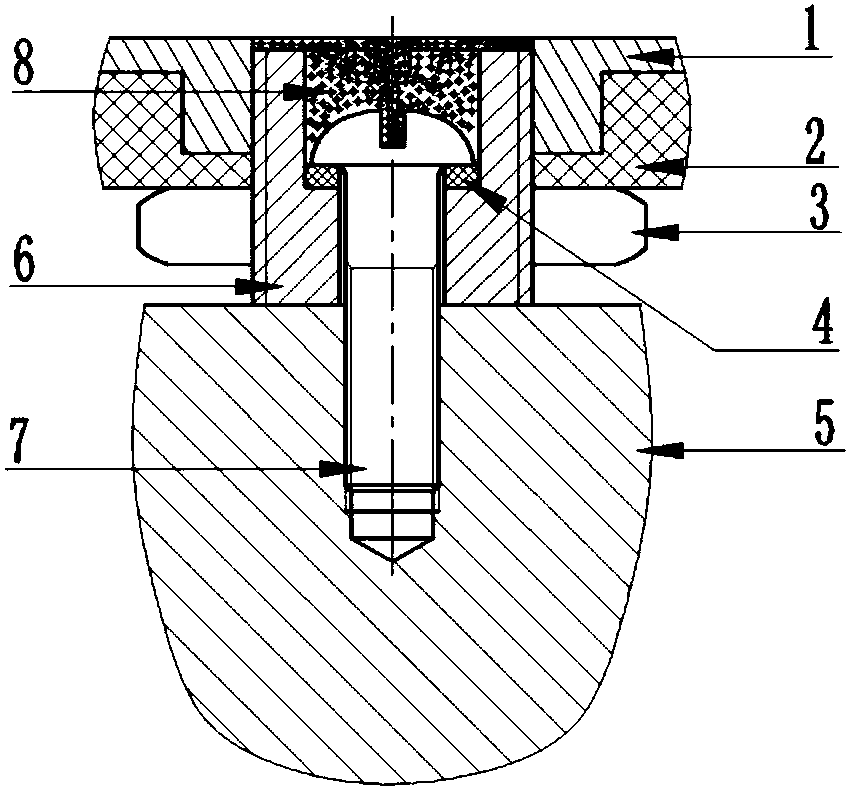

[0018] Such as figure 1 As shown, the connection structure of the integrated heat protection and component installation includes cabin body 1; heat insulation layer 2; hexagonal thin nut 3; heat insulation sealing gasket 4; component equipment 5; threaded bush 6; Bolt 7; heat insulation sealing putty 8. Among them, the cabin body 1 is made with mounting bosses, and the number of bosses arranged in the circumferential direction and the course direction depends on the load and the weight of the finished equipment 5, and the bosses are provided with internal thread holes, and the forming material of the cabin body 1 needs to be similar to titanium. Alloy light-weight high-temperature-resistant materials to meet the requirements of weight loss and high-temperature-resistant environment; the heat insulation layer 2 is an integral plate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com