Monodisperse carboxy-modified quantum dot composite microspheres, preparation method and application thereof

A carboxyl-modified and composite microsphere technology, which is applied in the direction of analytical materials, measuring devices, instruments, etc., can solve the problems of wide particle size distribution, unstable chemical properties, and limited application range, so as to reduce loss and simplify operation , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

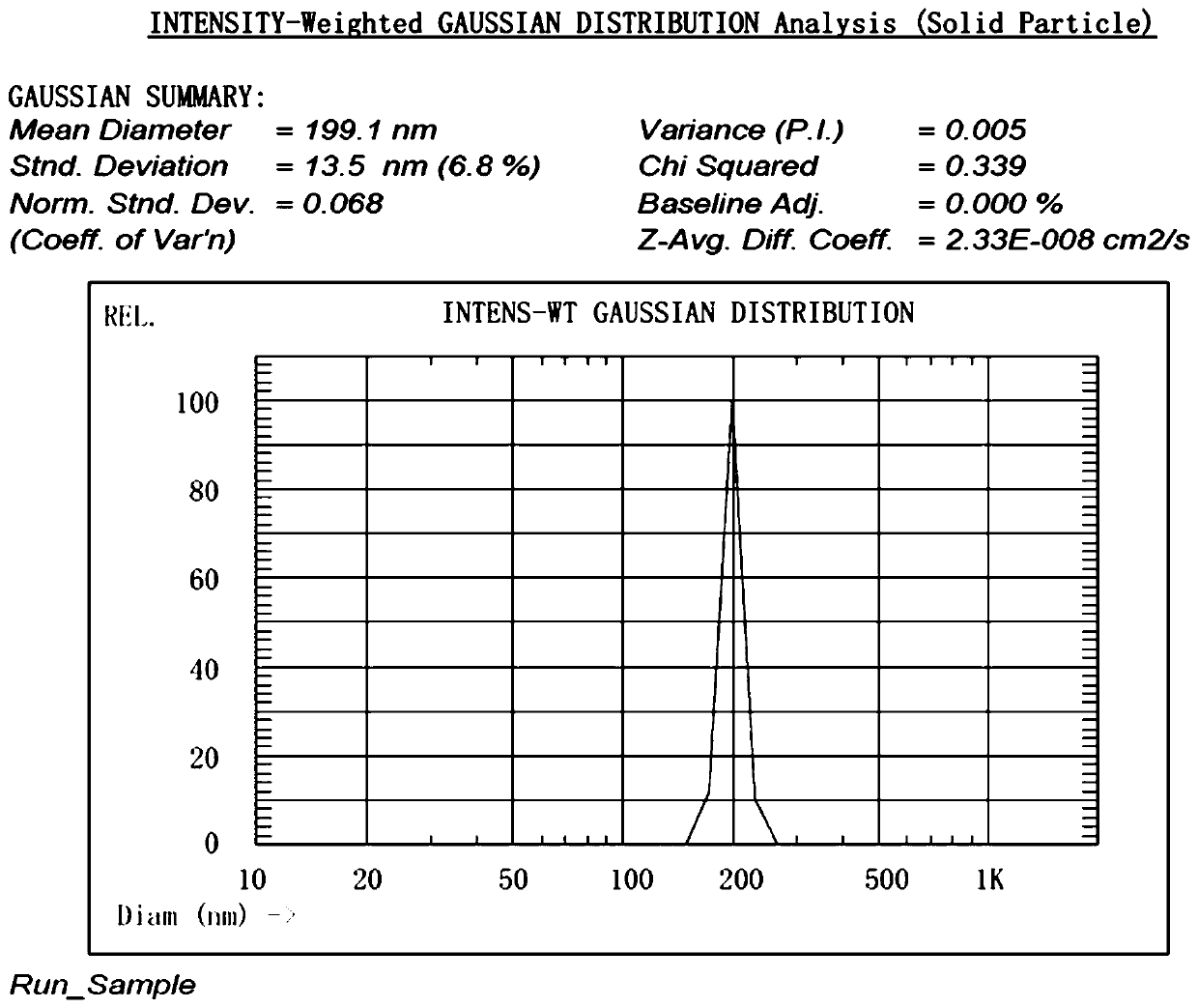

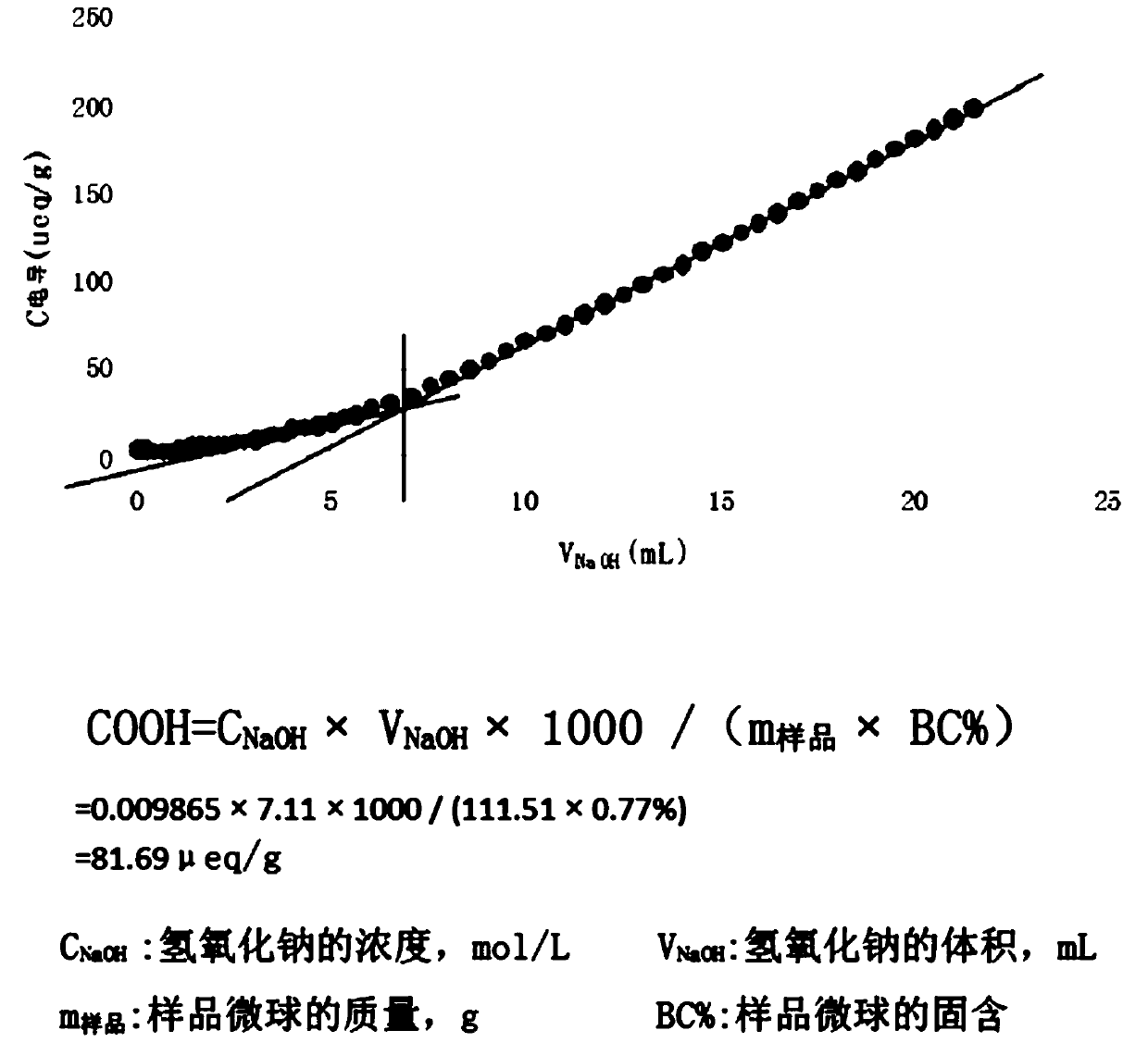

[0045] This embodiment provides a one-step method for preparing monodisperse polystyrene quantum dot composite microspheres containing carboxyl groups on the surface. The specific steps are as follows:

[0046] Oil-soluble quantum dot nanoparticles are dissolved in n-octane to form a quantum dot solution with a mass fraction of 10%. Weighing 20mg sodium dodecylsulfonate is dissolved in 40g distilled water to obtain sodium dodecylsulfonate aqueous solution, and then 2g of the quantum dot solution was added to the aqueous solution of sodium dodecylsulfonate for mixing, and the mixed solution was treated with a homogenizer at low temperature to obtain a quantum dot miniemulsion.

[0047] Weigh 80mg of sodium dodecylsulfonate and dissolve in 80g of distilled water to obtain an aqueous solution of sodium dodecylsulfonate, then mix 3.2g of styrene monomer with 40mg of superhydrophobic agent hexadecane, and pack it into the monomer tank. Nitrogen protection was applied, and pressure ...

Embodiment 2

[0050] This embodiment provides a one-step method for preparing monodisperse polystyrene quantum dot composite microspheres containing carboxyl groups on the surface. The specific steps are as follows:

[0051] Oil-soluble quantum dot nanoparticles are dissolved in n-octane to form a quantum dot solution with a mass fraction of 50%. Weighing 20mg sodium dodecylsulfonate is dissolved in 100g distilled water to obtain sodium dodecylsulfonate aqueous solution, and then 1 g of the quantum dot solution was added to the aqueous solution of sodium dodecylsulfonate for mixing, and the mixed solution was treated with a homogenizer at low temperature to obtain a quantum dot miniemulsion.

[0052] Weigh 80mg of sodium dodecylsulfonate and dissolve in 120g of distilled water to obtain an aqueous solution of sodium dodecylsulfonate, then mix 12g of styrene monomer with 120mg of superhydrophobic agent hexadecane, put it into a monomer tank, and pass Under nitrogen protection, pressure is ap...

Embodiment 3

[0055] This embodiment provides a one-step method for preparing monodisperse polystyrene quantum dot composite microspheres containing carboxyl groups on the surface. The specific steps are as follows:

[0056] Oil-soluble quantum dot nanoparticles are dissolved in n-octane to form a quantum dot solution with a mass fraction of 20%, and weighing 20 mg of sodium dodecylsulfonate is dissolved in 50 g of distilled water to obtain sodium dodecylsulfonate. aqueous solution, and then 1 g of the quantum dot solution was added to the aqueous solution of sodium dodecylsulfonate for mixing, and the mixed solution was treated with a homogenizer at low temperature to obtain a quantum dot miniemulsion.

[0057] Weigh 80mg of sodium dodecylsulfonate and dissolve in 100g of distilled water to obtain an aqueous solution of sodium dodecylsulfonate, then mix 5g of styrene monomer with 80mg of superhydrophobic agent hexadecane, put it into the monomer tank, and pass Under nitrogen protection, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com