Continuous production equipment for integrating synthesis and modification of nano material and method thereof

A technology of nanomaterials and production equipment, which is applied in chemical methods, chemical instruments and methods, and nanotechnology for liquid-liquid reactions, and can solve problems such as short residence time of reaction liquids, difficulty in controlling particle size and crystallinity, and achieve High crystallinity, high uniformity, and the effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments, and the advantages and characteristics of the present invention will become clearer along with the description. However, these embodiments are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

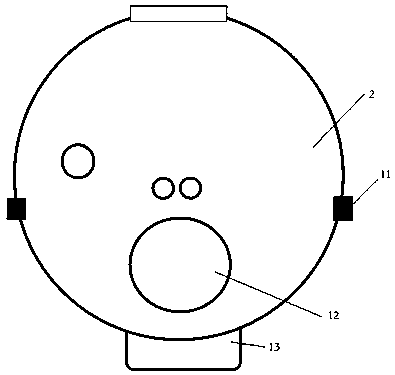

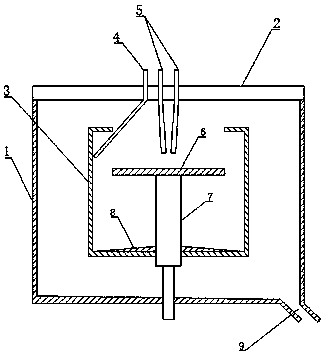

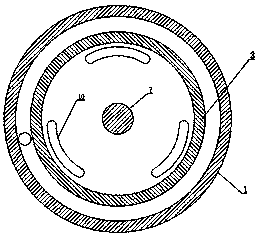

[0031] see Figure 1 to Figure 4 , the present invention relates to an integrated continuous production equipment for the synthesis and modification of nanomaterials, comprising an outer cylinder 1, an inner cylinder 3 and a disk 6 arranged in sequence from outside to inside, the outer cylinder 1, the inner cylinder The body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com