In-vivo phase transition tumor targeted nanobubble, its preparation method and application

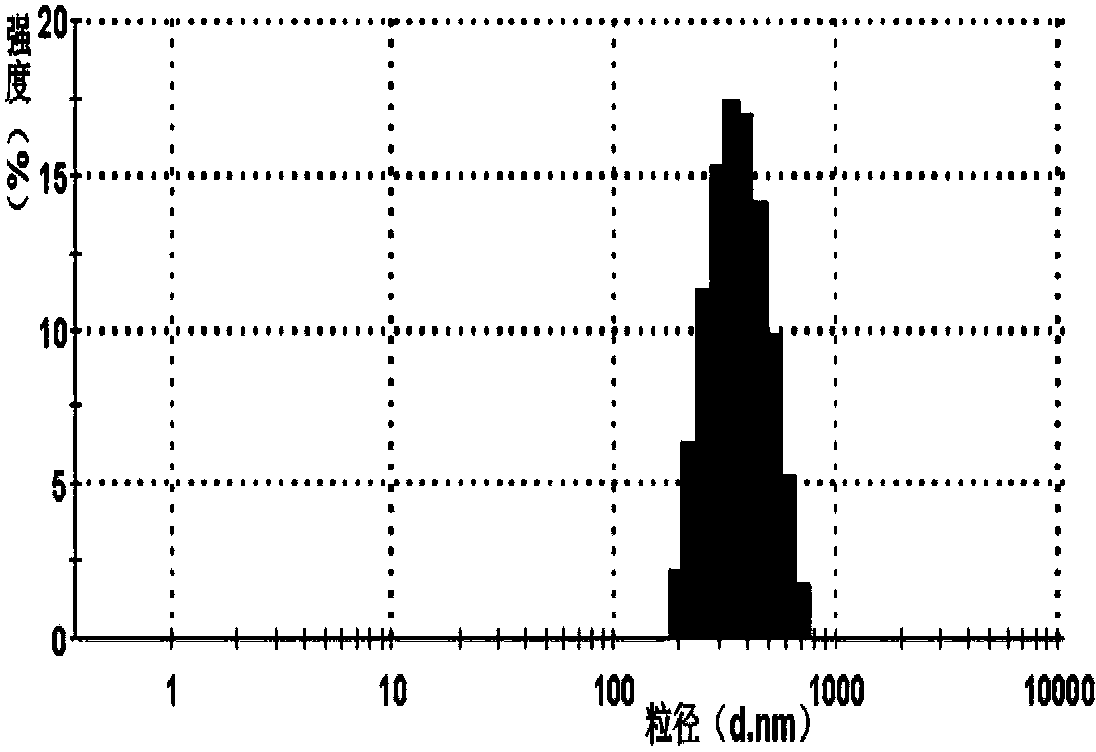

A technology of tumor targeting and nanobubbles, which is applied in the field of biomedicine, can solve the problems of loss of biological activity of targeting factors, poor reproducibility of preparation process, difficulty in obtaining microbubbles, etc., achieves highly uniform particle size, easy large-scale preparation, Effects that improve accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Preparation of copolymer

[0065] Referring to literature methods (S.Penczek, et al. Poly J. Chem., 2001, 75: 117-181; K. W. Leong, et al. J. Control. Rel., 2003, 92: 39-48.), synthesize poly Phosphate-polyester amphiphilic block copolymer.

[0066] Use 2-chloro-oxygen-1,3,2-dioxopentacycline phosphate and ethanol to synthesize ethyl phosphate ethyl ester, dissolve 0.29mol 2-chloro-oxygen-1,3,2-dioxopentacycline phosphate in In 250mL of dried benzene, cool down to -5°C, slowly drop the mixture of 0.29mol ethanol and 0.29mol triethylamine into the benzene solution under stirring, and keep the temperature at -5°C during the dropping process. After the dropwise addition was completed, the reaction was carried out at room temperature for 1.5h. By-products were removed by filtration, and ethyl ethyl phosphate was obtained by distillation. The copolymerization reaction of ethyl ethyl phosphate and D,L-lactide was carried out with triisobutylaluminum as the initiator. ...

Embodiment 2

[0073] (1) Preparation of copolymer

[0074] Adopt 2-chloro-oxygen-1,3,2-dioxopentacycline phosphate and isopropanol to synthesize ethyl phosphate isopropyl ester with the method of embodiment 1, take ethyl phosphate isopropyl ester and L-lactide as The polymerized monomer is subjected to a copolymerization reaction to obtain a polyethyl phosphate isopropyl ester-poly L-lactide copolymer. The number average molecular weight of the synthesized product measured by GPC was 26000, and the block ratio of phosphate ester and polyester segment was 1:2.

[0075] (2) Preparation of lactoferrin-coupled copolymers

[0076] References (M. Elfinger, et al. Biomaterials, 2007, 28(23): 3448-3455; K. Hu, et al. J. Control. Rel., 2009, 134(1): 55-61.) Methods Lactoferrin was chemically coupled to polyphosphate-polylactide copolymer. First, polyethylphosphoric acid isopropyl ester-poly L-lactide copolymer is subjected to aminolysis reaction to obtain polyethylphosphoramide-poly L-lactide cop...

Embodiment 3

[0080] (1) Preparation of copolymer

[0081] Adopt 2-chloro-oxygen-1,3,2-dioxopentacycline phosphate and ethanol to synthesize ethyl phosphate ethyl ester with the method of embodiment 1, use ethyl phosphate ethyl ester and glycolide-lactide oligomer Carry out copolymerization reaction for polymerizing monomers, and synthesize polyethyl phosphate-polyglycolide-lactide copolymer. The number average molecular weight of the synthesized product measured by GPC was 17500, and the block ratio of phosphate ester and polyester segment was 1:4.

[0082] (2) Preparation of RGD peptide-coupled copolymers

[0083] The same method as in Example 2 was used to prepare the RGD peptide-coupled polyethylene ethyl phosphate-polyglycolide-lactide copolymer.

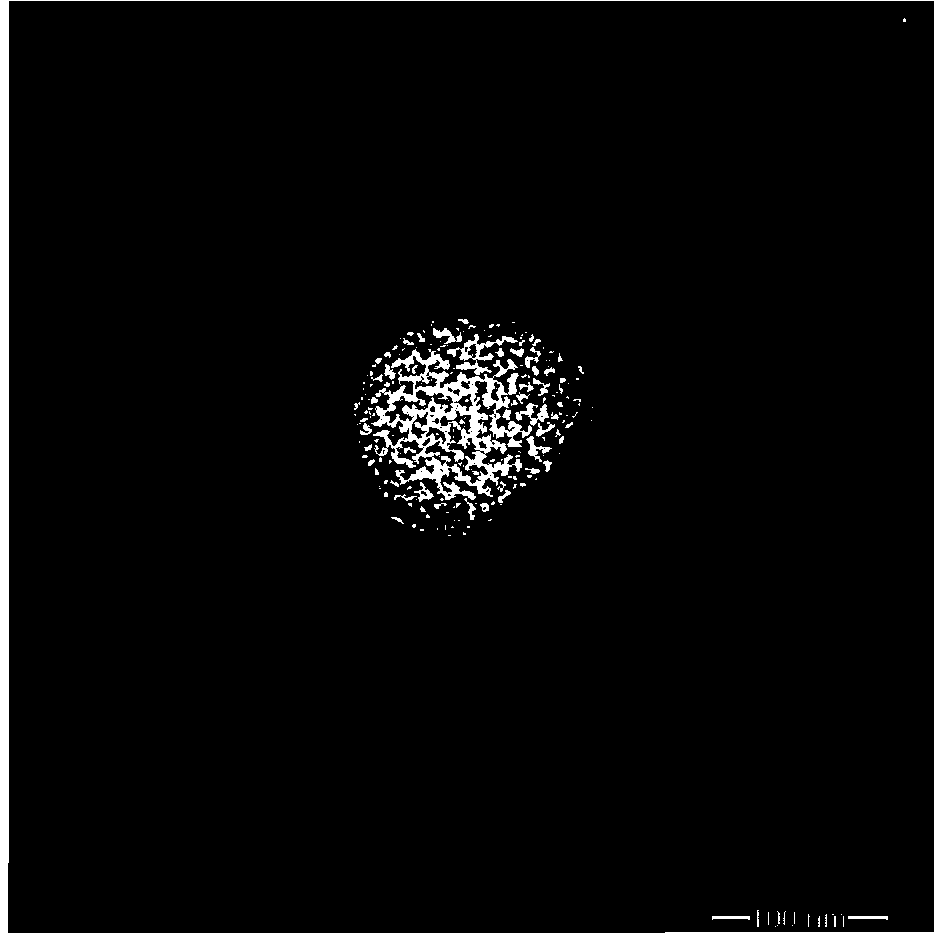

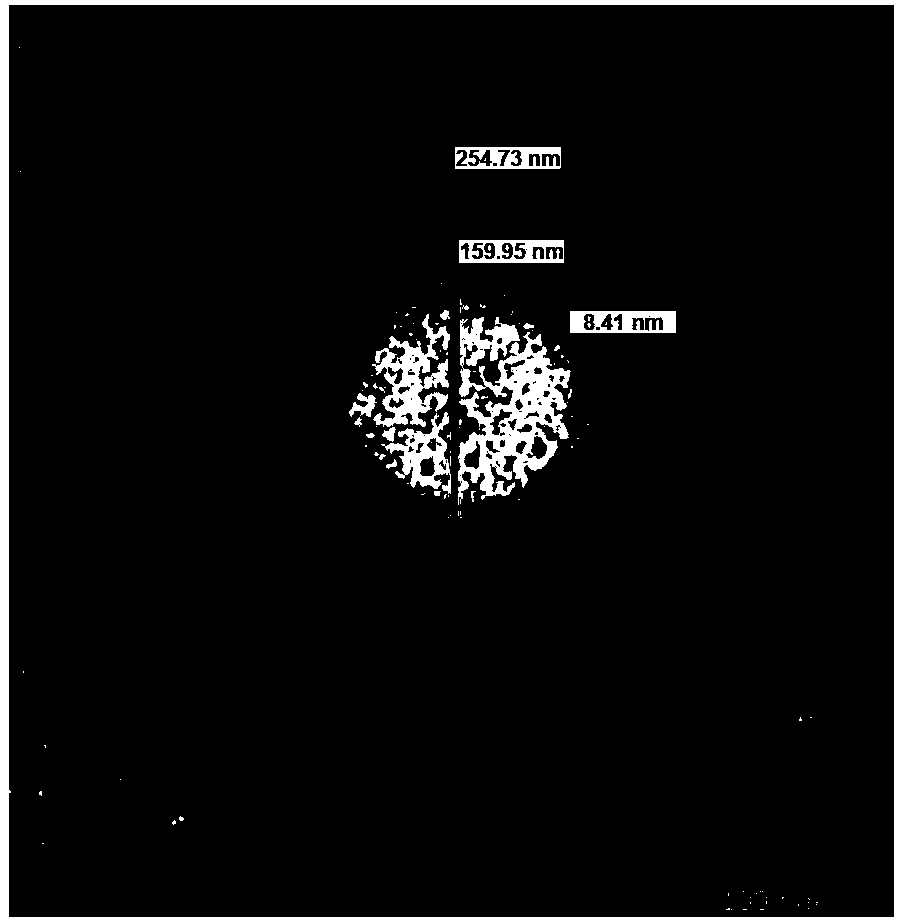

[0084] (3) Preparation of nanobubbles

[0085] RGD peptide-coupled polyethylene ethyl phosphate-polyglycolide-lactide copolymer nanobubbles were prepared by pre-double emulsion-hollow membrane tube emulsification method. The hollow membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com