Preparation method of multilayer assembled micron-scale monodisperse polystyrene magnetic composite microspheres

A technology of polystyrene microspheres and magnetic composite microspheres, which is applied in the field of preparation of multilayer assembly of micron-scale monodisperse polystyrene magnetic composite microspheres, can solve the problem of particle size of magnetic polymer microspheres that do not have monodispersity and magnetic polymer microspheres Problems such as wide distribution and limited scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

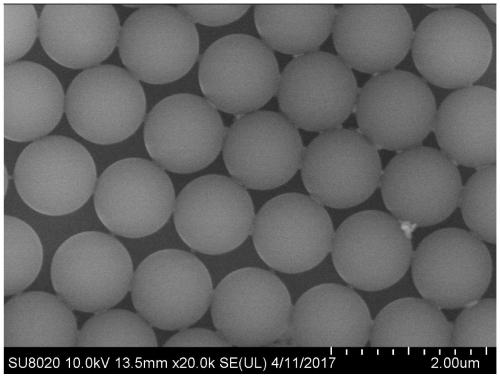

Embodiment 1

[0027] This embodiment provides a method for preparing multilayer assembled micron-sized monodisperse polystyrene magnetic composite microspheres, the specific steps are as follows:

[0028] (1) Synthesis of polystyrene microspheres: Take a 250ml round bottom flask, add 3g of polyvinylpyrrolidone (Mw=55000), 100mL of ethanol and 10mL of water, and stir to obtain a homogeneous solution. Weigh 0.08 g of azobisisobutyronitrile as an initiator and dissolve it in 8 mL of distilled styrene monomer. Add the styrene monomer solution dissolved with azobisisobutyronitrile into the homogeneous solution obtained above, stir, protect with nitrogen, raise the reaction temperature to 70°C, and react at 150rpm / min for 20 hours. After the reaction time is up, centrifuge, remove the supernatant, disperse with ethanol, repeat the dispersion six times, and dry in vacuum at 30°C for 24 hours to obtain polystyrene microspheres with a particle size of about 1 μm.

[0029] (2) Sulfonation of polysty...

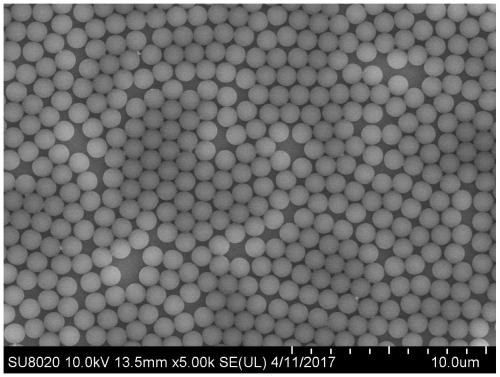

Embodiment 2

[0035] This embodiment provides a method for preparing multilayer assembled micron-sized monodisperse polystyrene magnetic composite microspheres, the specific steps are as follows:

[0036] (1) Synthesis of polystyrene microspheres: Take a 250ml round bottom flask, add 2.0g polyvinylpyrrolidone (Mw=55000) and 120mL ethanol, stir to obtain a homogeneous solution. Weigh 0.2 g of azobisisobutyronitrile as an initiator and dissolve it in 30 mL of distilled styrene monomer. Add the styrene monomer solution dissolved with azobisisobutyronitrile into the homogeneous solution obtained above, stir, protect with nitrogen, raise the reaction temperature to 68°C, and react at 150rpm / min for 20 hours. After the reaction time is up, centrifuge, remove the supernatant, disperse with ethanol, repeat six times, and vacuum dry at 30° C. for 24 hours to obtain polystyrene microspheres with a particle size of 3 μm.

[0037] (2) Sulfonation of polystyrene microspheres: Take a 100mL round-bottome...

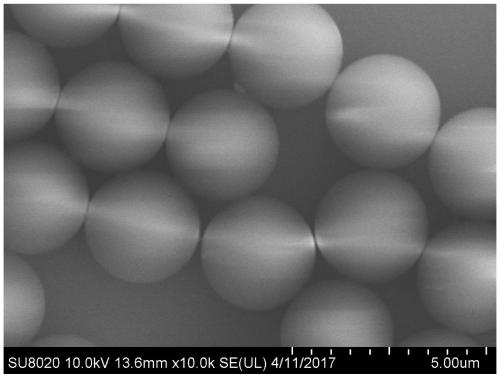

Embodiment 3

[0042] This embodiment provides a method for preparing multilayer assembled micron-sized monodisperse polystyrene magnetic composite microspheres, the specific steps are as follows:

[0043] (1) Synthesis of polystyrene microspheres: Take a 250ml round bottom flask, add 4.0g polyvinylpyrrolidone (Mw=55000), 40mL ethanol and 60mL ethylene glycol methyl ether, and stir to obtain a homogeneous solution. Weigh 0.3 g of azobisisobutyronitrile as an initiator and dissolve it in 30 mL of distilled styrene monomer. Add the styrene monomer solution dissolved with azobisisobutyronitrile into the homogeneous solution obtained above, stir, protect with nitrogen, raise the reaction temperature to 72°C, and react at 150rpm / min for 20 hours. After the reaction time is up, centrifuge, remove the supernatant, disperse with ethanol, repeat six times, and dry in vacuum at 30° C. for 24 hours to obtain polystyrene microspheres with a particle size of 6 μm.

[0044](2) Sulfonation of polystyrene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com