Diameter measurement method based on shear ruler

A technology of diameter measurement and scissors, which is applied in the field of diameter measurement based on scissors, can solve the problems of high requirements for the operating environment of the measurement object, limited range of measurement diameter, inconvenient portability and measurement, etc., so as to facilitate remote data collection, Easy to implement, innovative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

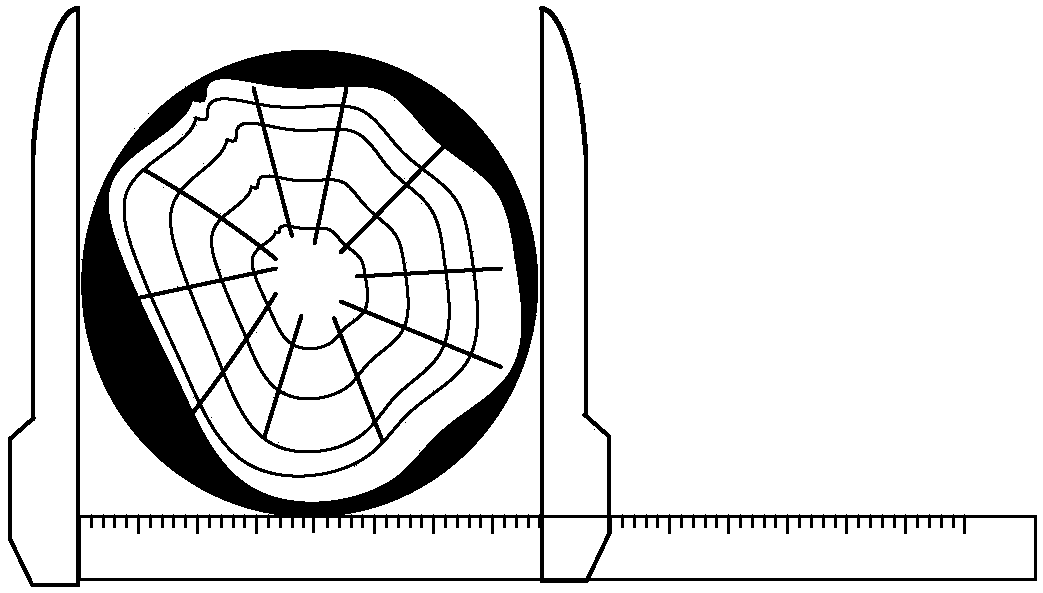

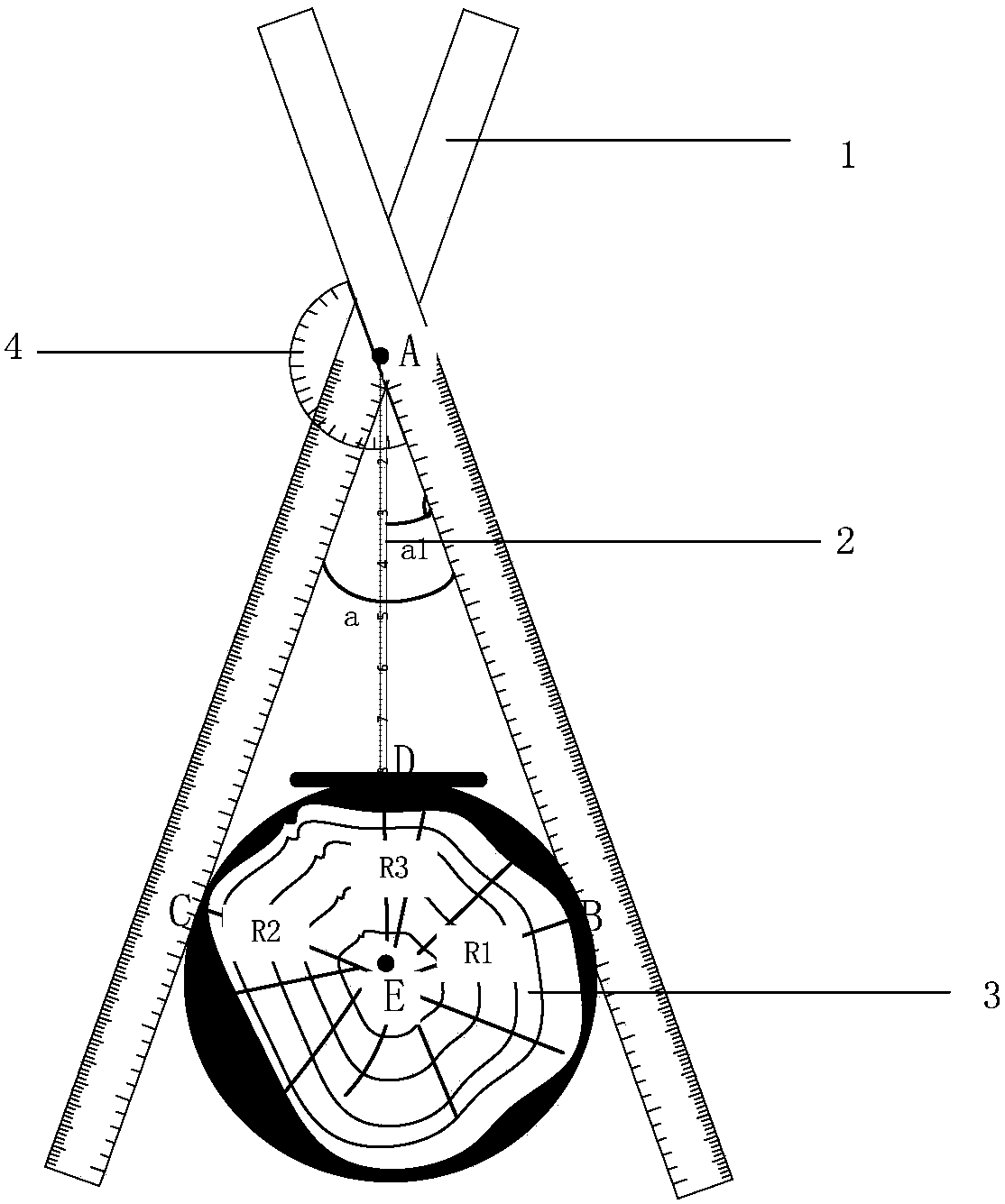

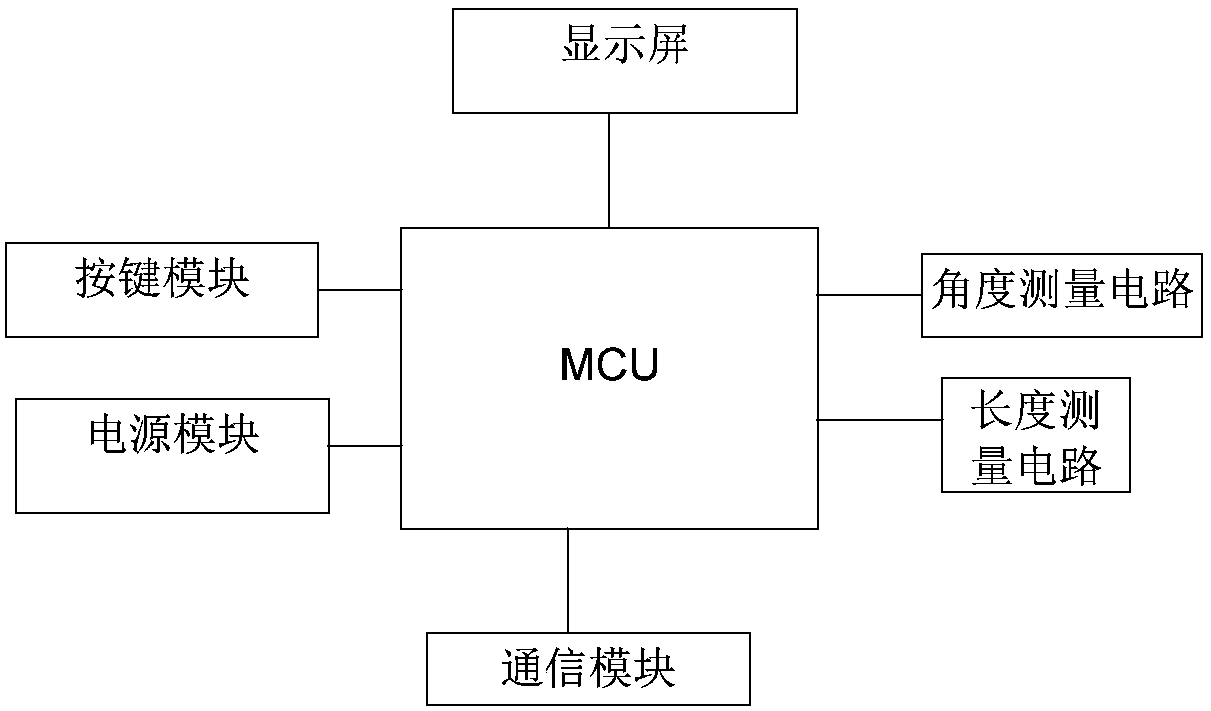

[0066] Embodiment 1: as figure 2, a kind of diameter measuring method based on scissors, is characterized in that, realizes diameter measurement by scissors 1, straightedge and protractor 4; The first end of straightedge links to each other with hinge point A of scissors, the second of straightedge The end is used to contact the surface of the measured object (such as the trunk 3); the measured object is cylindrical or cylindrical;

[0067] The measurement steps are as follows:

[0068] Step 1: Open the scissors;

[0069] The opening direction is perpendicular to the axis of the measured object;

[0070] Step 2: Put the second end of the ruler against the surface of the measured object; and clamp the two arms of the opened scissors to the measured object;

[0071] Step 3: Reading;

[0072] The read data includes the angle data measured by the protractor;

[0073] Step 4: Calculate the diameter;

[0074] The diameter Φ of the measured object is calculated based on the le...

Embodiment 2

[0082] Such as Figure 2-5 , a kind of diameter measuring method based on scissors, is characterized in that, realizes diameter measurement by scissors 1, straightedge and protractor 3; The first end of straightedge is connected with hinge point A of scissors, the second of straightedge The end is used to contact the surface of the measured object; the measured object is cylindrical or cylindrical;

[0083] The measurement steps are as follows:

[0084] Step 1: Open the scissors;

[0085] The opening direction is perpendicular to the axis of the measured object;

[0086] Step 2: Put the second end of the ruler against the surface of the measured object; and clamp the two arms of the opened scissors to the measured object;

[0087] Step 3: Reading;

[0088] The read data includes the angle data measured by the protractor;

[0089] Step 4: Calculate the diameter;

[0090] The diameter Φ of the measured object is calculated based on the length of the ruler and the opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com