Waste liquid liquid-level detection system with failure self-detection function, and detection method

A technology of liquid level detection and fault self-test, applied in buoy liquid level indicators, liquid/fluid solid measurement, measuring devices, etc., can solve problems such as high equipment maintenance costs and frequent failures, and reduce manpower consumption and Low probability of occurrence and the effect of reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

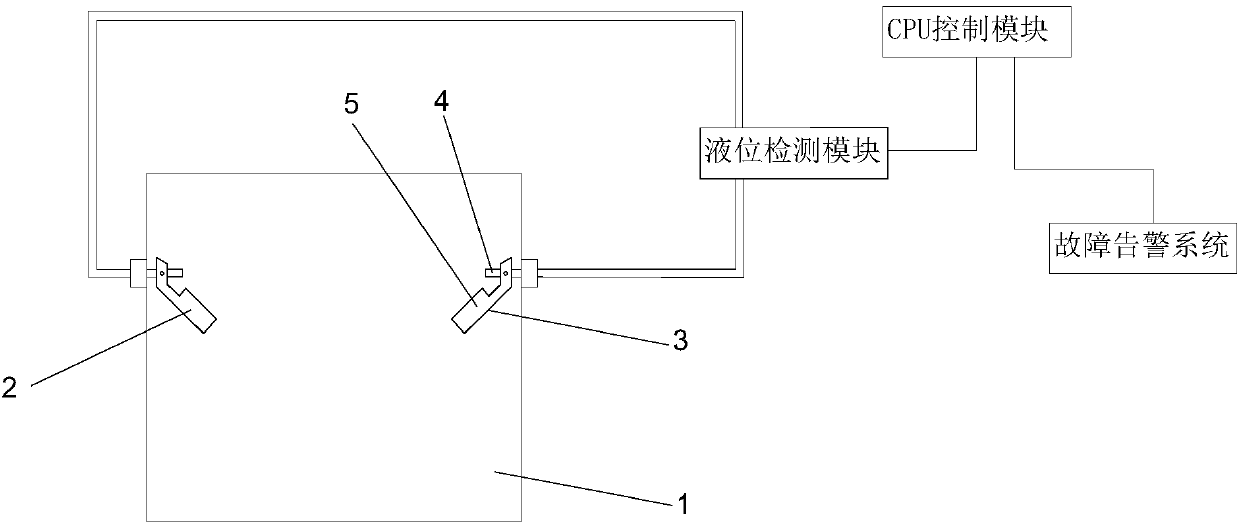

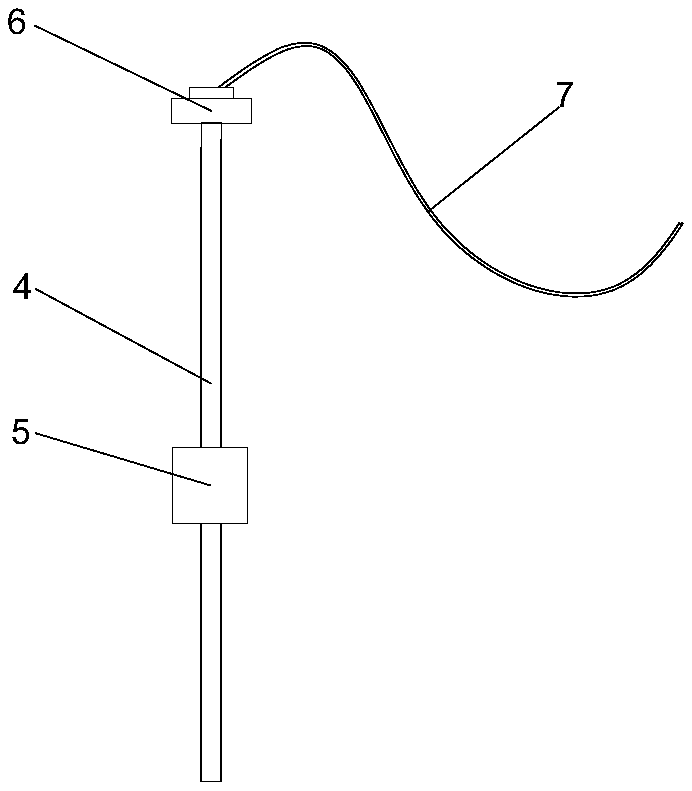

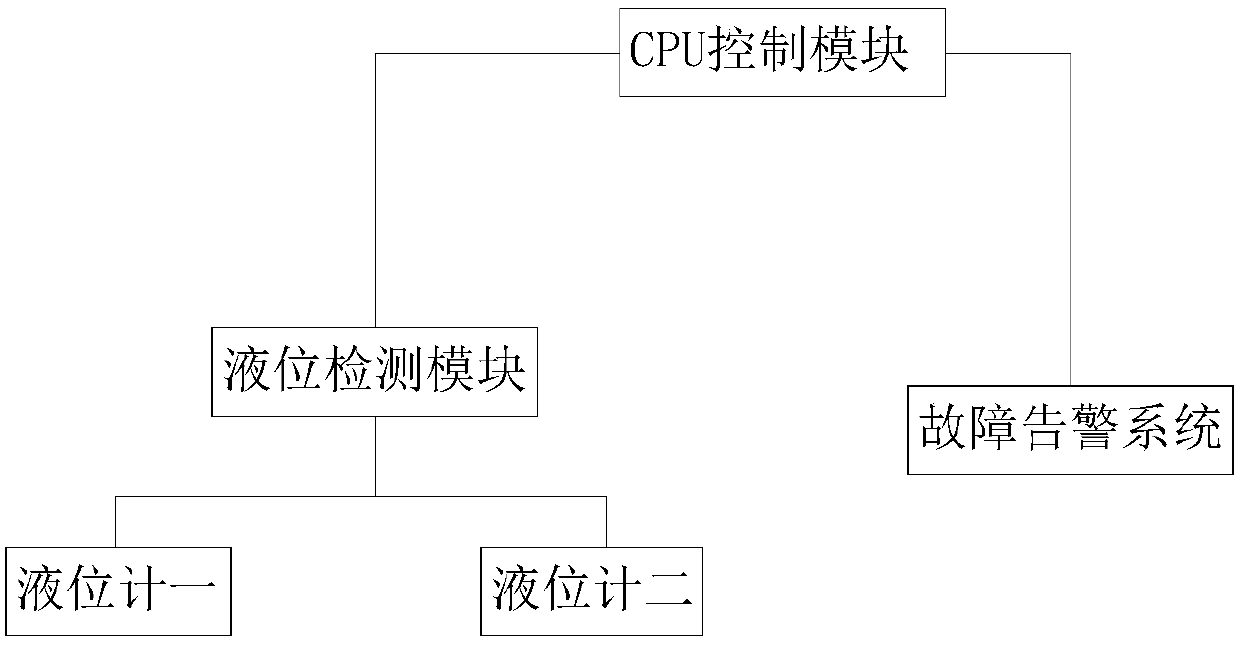

[0034] Such as figure 1 , image 3 As shown, the waste liquid level detection system with fault self-checking function of embodiment 1 includes a CPU control module, a fault alarm system and a liquid level detection system, and the liquid level detection system includes a liquid level detection module, a liquid level gauge-2 and The liquid level gauge 2 3 , the liquid level gauge 1 2 and the liquid level gauge 2 3 are respectively connected and communicated with the liquid level detection module. The liquid level detection module is connected with the CPU control module, and the CPU control module is connected with the fault alarm system. Liquid level gauge 1 2 and liquid level gauge 2 3 are duckbill float level switches. The liquid level gauge 1 2 and the liquid level gauge 2 3 are installed at the same level in the liquid storage tank 1 . Such as figure 1 As shown, the duckbill float liquid level switch includes a stator 4 and a float 5 , the stator 4 is fixed on the inn...

Embodiment 2

[0037] The waste liquid level detection method with fault self-diagnosis function of embodiment 2 is based on the waste liquid liquid level detection system with fault self-diagnosis function of embodiment 1. Such as Figure 4 , the waste liquid level detection method with fault self-checking function of embodiment 2, comprises the following steps:

[0038] 1. In the liquid level detection module, the liquid level detection fault record is initialized:

[0039] (1) Establish and initialize the number of times N of liquid level detection fault records, record N=0; then enter step (2),

[0040] 2. The liquid level detection system monitors the liquid level in the liquid storage tank in real time:

[0041] (2) Liquid level real-time monitoring: Liquid level gauge 1 and liquid level gauge 2 respectively monitor the liquid full state in the liquid storage tank in real time; when liquid level gauge 1 and / or liquid level gauge 2 detect a liquid full signal, the liquid level gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com