Glycerol adding system for filter stick forming machines

A filter rod forming machine, glycerin technology, applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of high pressure, hidden danger of material safety on production site, manual control of corrosion-resistant ball valve is not safe, etc., to avoid uncertainty, The effect of reducing the risk of glycerin spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The scheme of the present invention will be further described below in conjunction with the accompanying drawings.

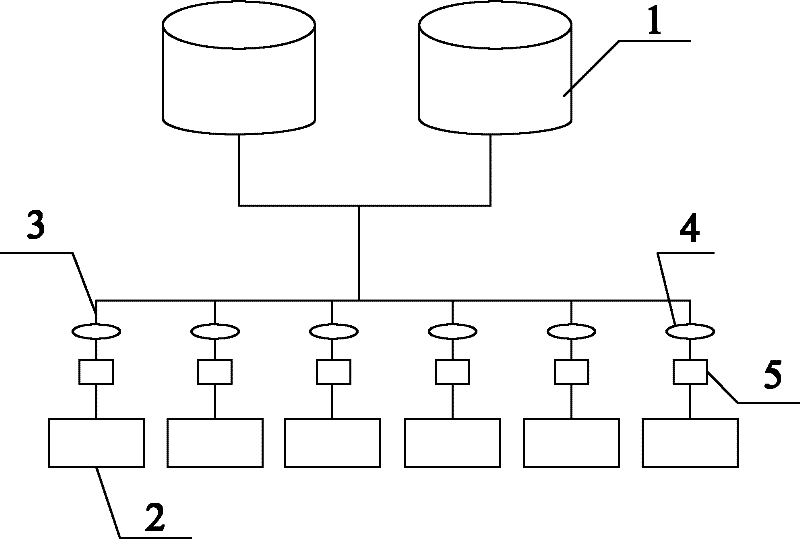

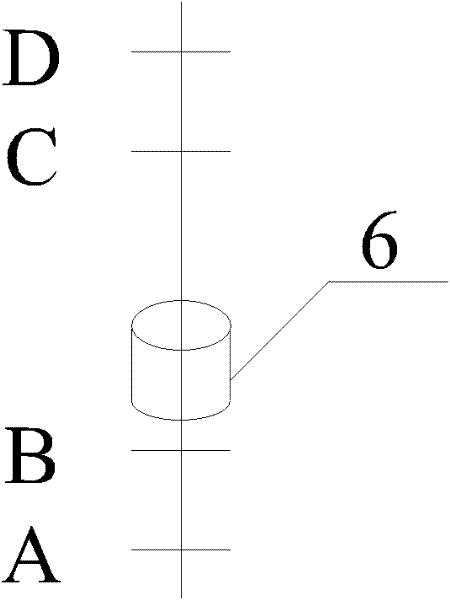

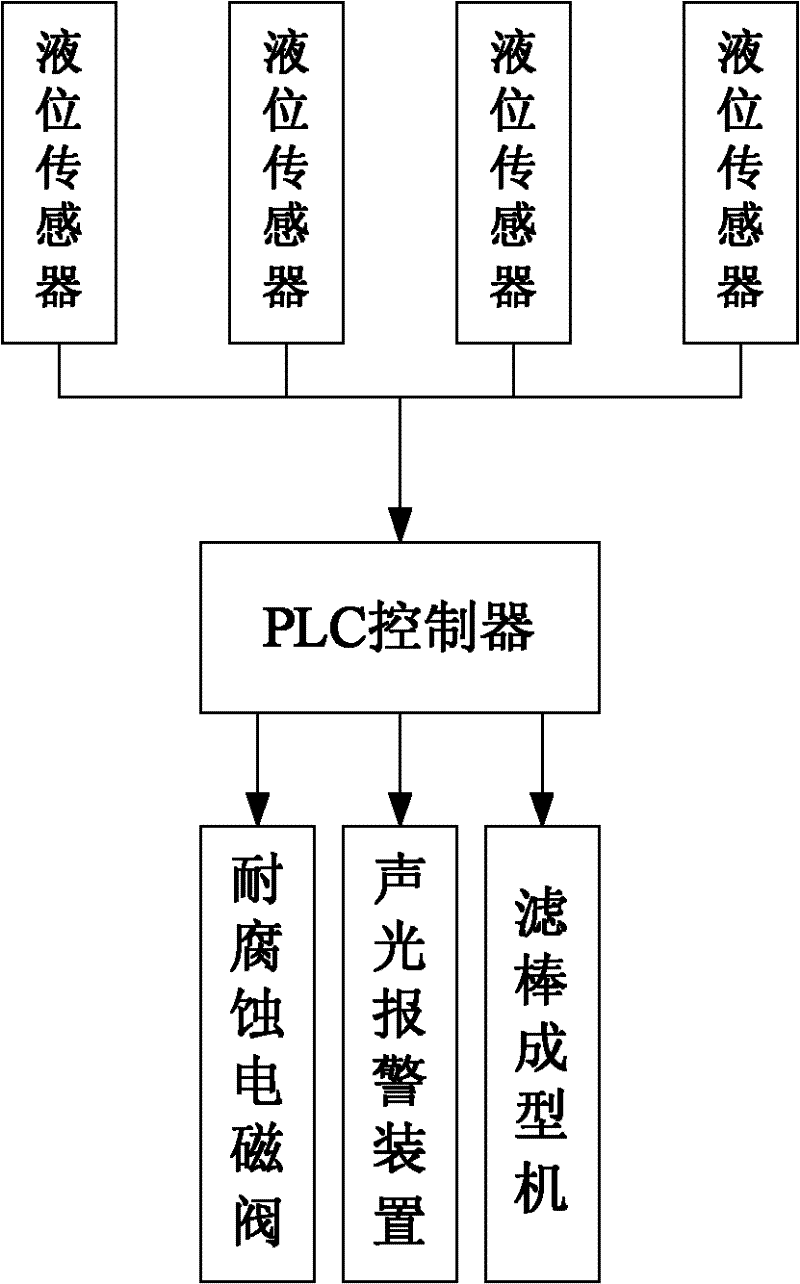

[0013] Such as figure 1 As shown, the present invention adds glycerol from the total glycerin tank 1 to several filter rod forming machine glycerin storage tanks 2, and each glycerin storage tank 2 communicates with the total glycerin tank 1 through a delivery branch pipe 3, and each delivery branch pipe 3 A corrosion-resistant ball valve 4 is provided, and each delivery branch pipe 3 is also provided with a corrosion-resistant solenoid valve 5. The corrosion-resistant solenoid valve 5 is located between the corrosion-resistant ball valve 4 and the glycerin storage tank 2, such as figure 2 As shown, each glycerin storage tank 2 is provided with a glycerin float switch 6, and four different heights A, B, C, and D of the inner wall of each glycerin storage tank 2 are respectively provided with liquid level sensors, and the signals of the four liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com