Optical lens

An optical lens and lens technology, which is applied in the field of optical lenses, can solve problems such as difficult separation, asymmetry, and large deformation of the lens surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

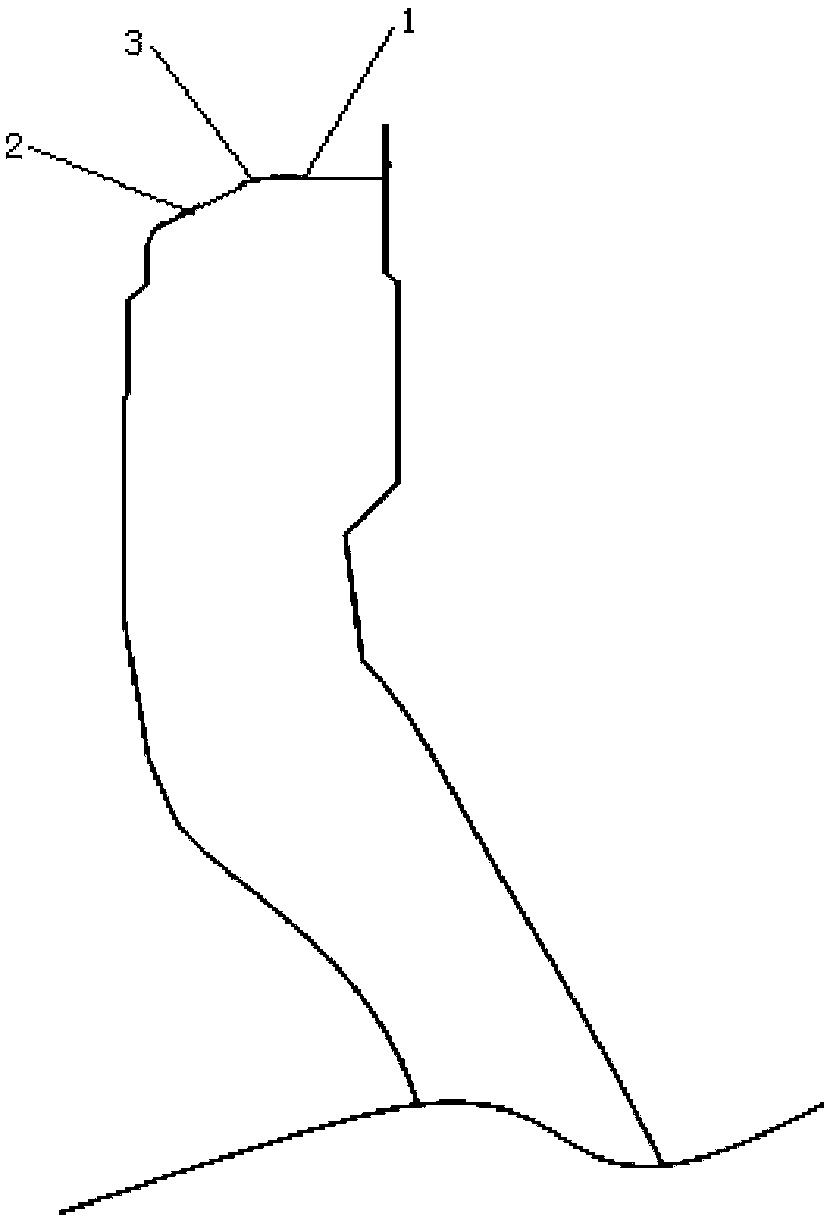

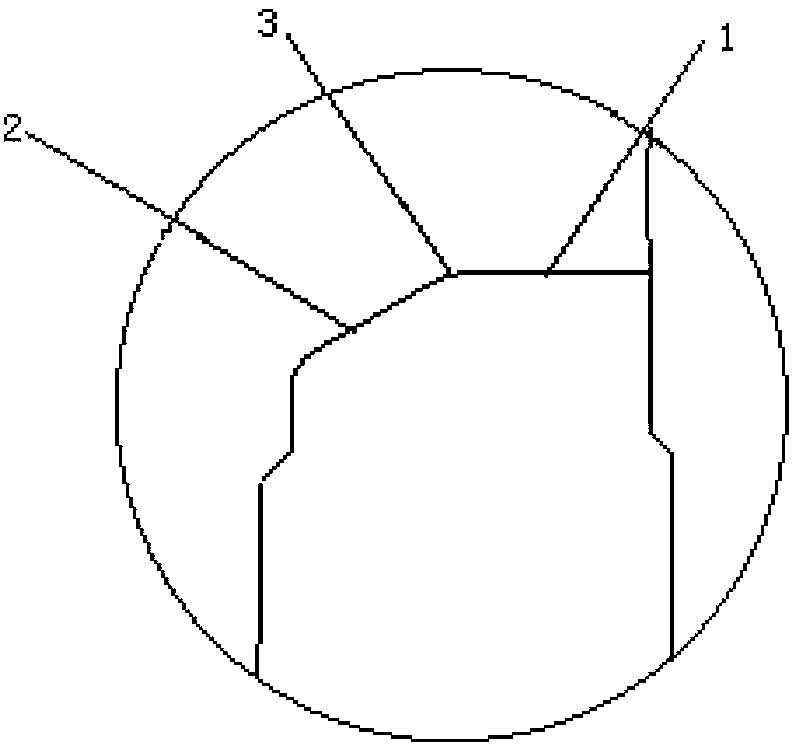

[0008] Such as figure 1 with figure 2 As shown, the optical lens of the present invention includes a curved surface of the lens and an outer diameter of the lens, the outer diameter of the lens is integrally formed with the curved surface of the lens, and the movable side of the outer diameter of the lens is composed of a straight section 1, a slope 2 and a connecting part 3 , the length of the straight section 1 is 0.08 mm to 0.2 mm, the demoulding slope of the slope 2 is 5° to 30°, and the radius of curvature of the connecting portion 3 is 0.05 to 0.1. During specific implementation, the length of the straight segment of the lens is 0.1 mm, the demoulding angle of the inclined surface is 15°, and the radius of curvature of the connecting portion is 0.08.

[0009] Control the length of the straight section 1 on the movable side of the outer diameter of the lens (also known as the male mold) within the range of 0.08mm to 0.2mm, and set the demoulding slope of 5° to 30° on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap