Plug-in type insulation sleeve

An insulating sleeve and plug-in technology, applied in the direction of insulators, insulators, electrical components, etc., can solve the problems of limited length of insulating sleeve, affect work efficiency, time-consuming connection, etc., achieve good elasticity and flexibility, and prolong service life , to achieve the effect of a stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

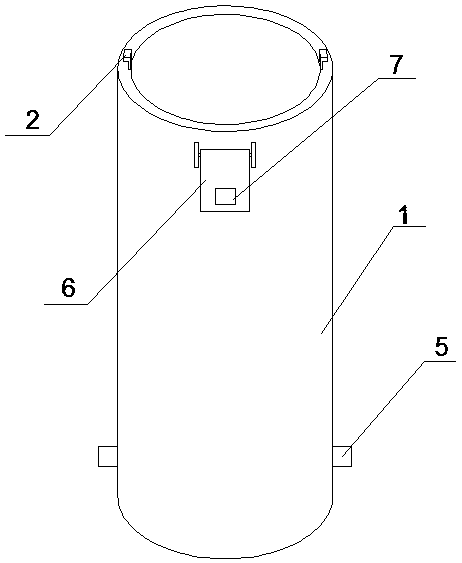

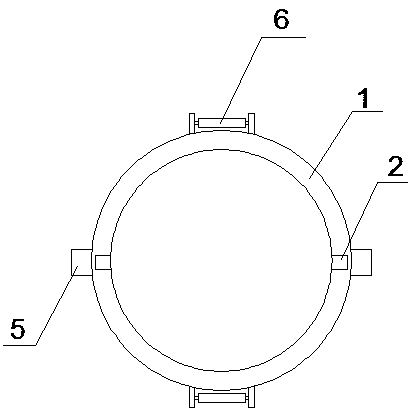

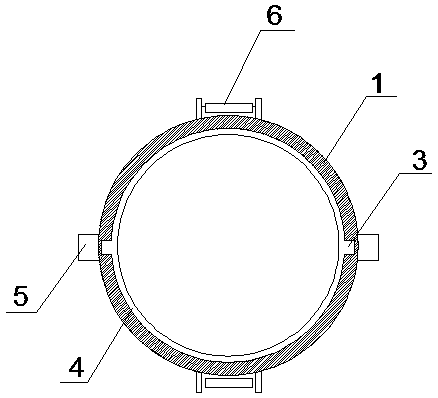

[0030] A plug-in insulating sleeve provided in this embodiment has a structure such as figure 1 As shown, including a pipe body 1, the upper end surface of the pipe body 1 is fixedly provided with an insertion rod 2, the insertion rod 2 of this embodiment is an inverted L shape, and the lower end surface of the pipe body 1 is provided with an insertion rod 2 2 matching socket 3, the lower end surface of the tube body 1 is provided with a cavity 4 for the insertion rod 2 to move, by inserting the insertion rod 2 into the socket 3 and then rotating, the lateral part of the insertion rod 2 is rotated to In the cavity 4, the upper and lower positions between the two insulating sleeves can be fixed;

[0031] The side of the pipe body 1 is provided with a bump 5, the bump 5 is located at the lower part of the side of the pipe body 1, two of the bumps 5 are arranged, and they are located on the same diameter of the end face of the pipe body 1, the pipe body 1 The side is hinged with...

Embodiment 2

[0040] A plug-in insulating sleeve provided in this embodiment has a structure such as figure 1 As shown, including a pipe body 1, the upper end surface of the pipe body 1 is fixedly provided with an insertion rod 2, the insertion rod 2 of this embodiment is an inverted L shape, and the lower end surface of the pipe body 1 is provided with an insertion rod 2 2 matching socket 3, the lower end surface of the tube body 1 is provided with a cavity 4 for the insertion rod 2 to move, by inserting the insertion rod 2 into the socket 3 and then rotating, the lateral part of the insertion rod 2 is rotated to In the cavity 4, the upper and lower positions between the two insulating sleeves can be fixed;

[0041] The side of the pipe body 1 is provided with a bump 5, the bump 5 is located at the bottom of the side of the pipe body 1, the side of the pipe body 1 is hinged with a cover plate 6, the cover plate 6 is located at the top of the side of the pipe body 1, and the cover plate 6 ...

Embodiment 3

[0050] A plug-in insulating sleeve provided in this embodiment has a structure such as figure 1 As shown, including a pipe body 1, the upper end surface of the pipe body 1 is fixedly provided with an insertion rod 2, the insertion rod 2 of this embodiment is an inverted L shape, and the lower end surface of the pipe body 1 is provided with an insertion rod 2 2 matching socket 3, the lower end surface of the tube body 1 is provided with a cavity 4 for the insertion rod 2 to move, by inserting the insertion rod 2 into the socket 3 and then rotating, the lateral part of the insertion rod 2 is rotated to In the cavity 4, the upper and lower positions between the two insulating sleeves can be fixed;

[0051] The side of the pipe body 1 is provided with a bump 5, the bump 5 is located at the bottom of the side of the pipe body 1, the side of the pipe body 1 is hinged with a cover plate 6, the cover plate 6 is located at the top of the side of the pipe body 1, and the cover plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com