Automatic full-process crawler-type honey harvesting machine and control method thereof

A fully automatic, control-based technology that is applied in the field of agricultural machinery to achieve the effects of reducing blockage, facilitating recycling and storage, and adapting to a wide range of sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

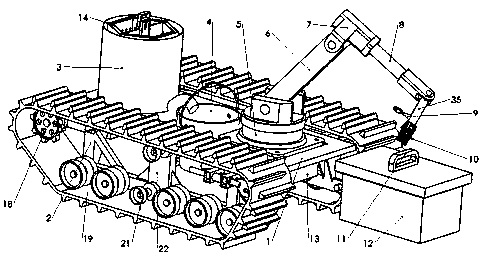

[0044] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

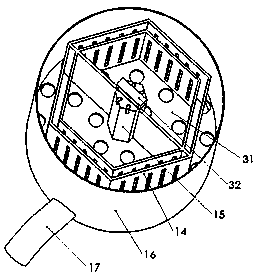

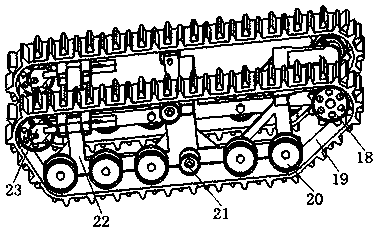

[0045] A crawler-type honey whole-process automatic harvesting machine, comprising a crawler-type traveling mechanism 2, a robotic arm and a honey extraction device 3 are sequentially arranged on the deck 1 of the crawler-type traveling mechanism 2 from front to rear, and the lower part of the deck 1 The chassis 22 is symmetrically installed with a large chassis wheel 20 and a small chassis wheel 21, and the front and rear sides above the large chassis wheel 20 and the small chassis wheel 21 are symmetrically installed with driving wheels 18 and driven wheels 23 respectively. The wheel 18, the driven wheel 23, the large chassis wheel 20 and the small chassis wheel 21 are connected by the track 19, and the driving wheel 18 is connected with the driving device. In order to facilitate the steering of the chassis 22, a differential c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com